Clutch assembly in a gearbox comprising two axially and radially adjoining clutches

A clutch device, clutch technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve problems such as associated defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

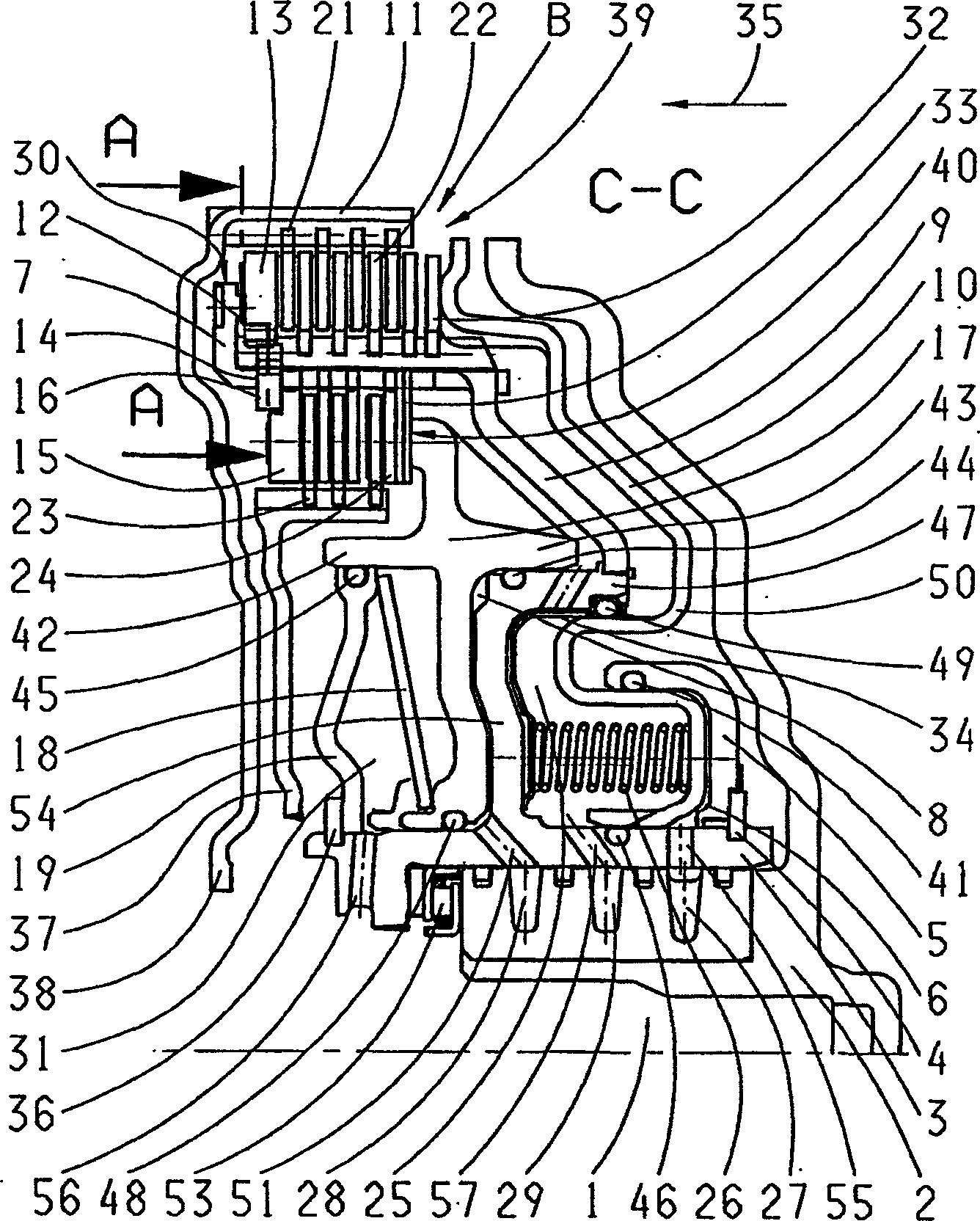

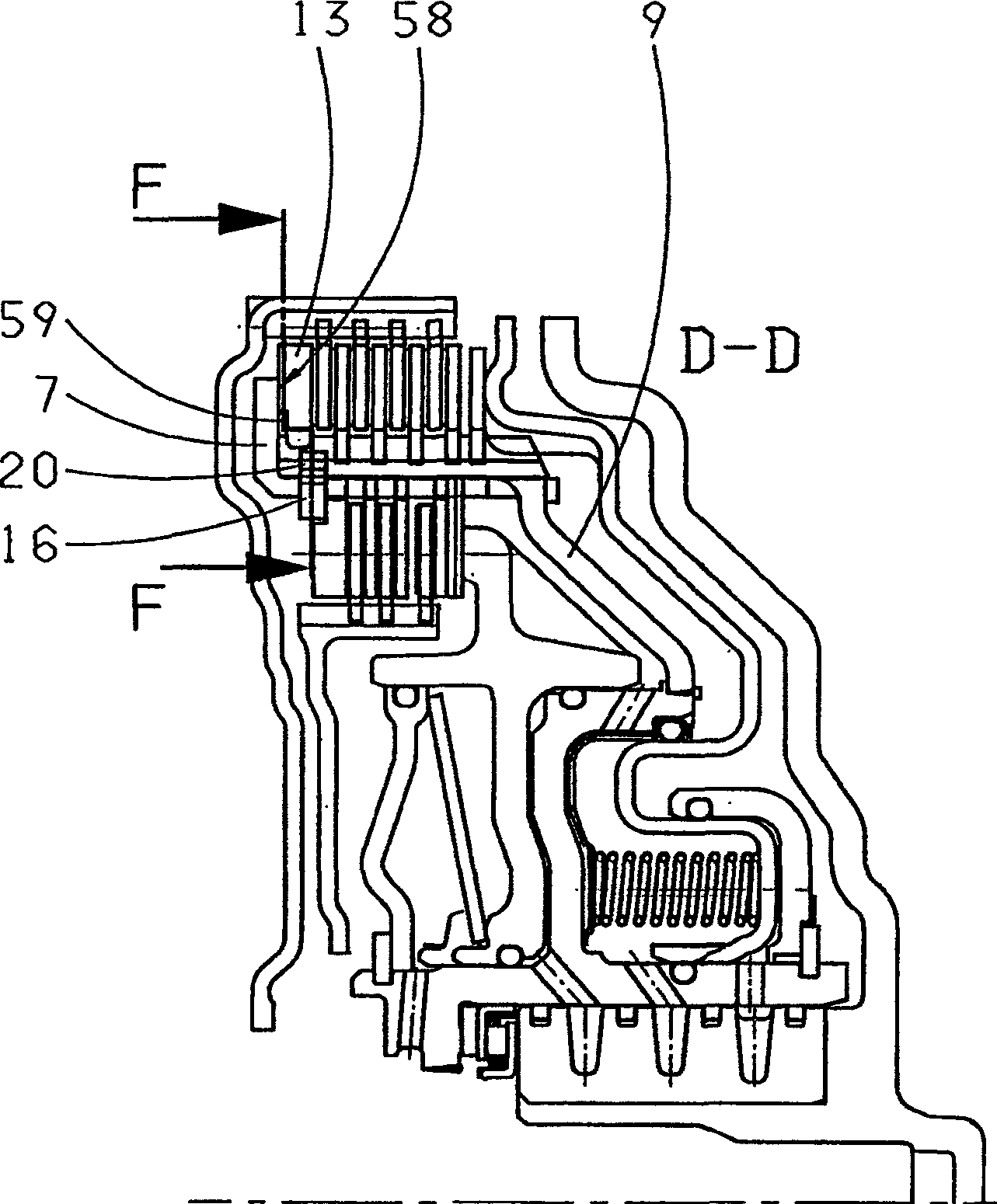

[0027] therefore figure 1 A transmission is shown in cross-section in the region of two multi-disk clutches B and E, which are arranged radially and axially directly adjacent in a transmission housing 2 . The design of the clutch arrangement selected here provides that the clutch E is arranged radially directly below the outer clutch B.

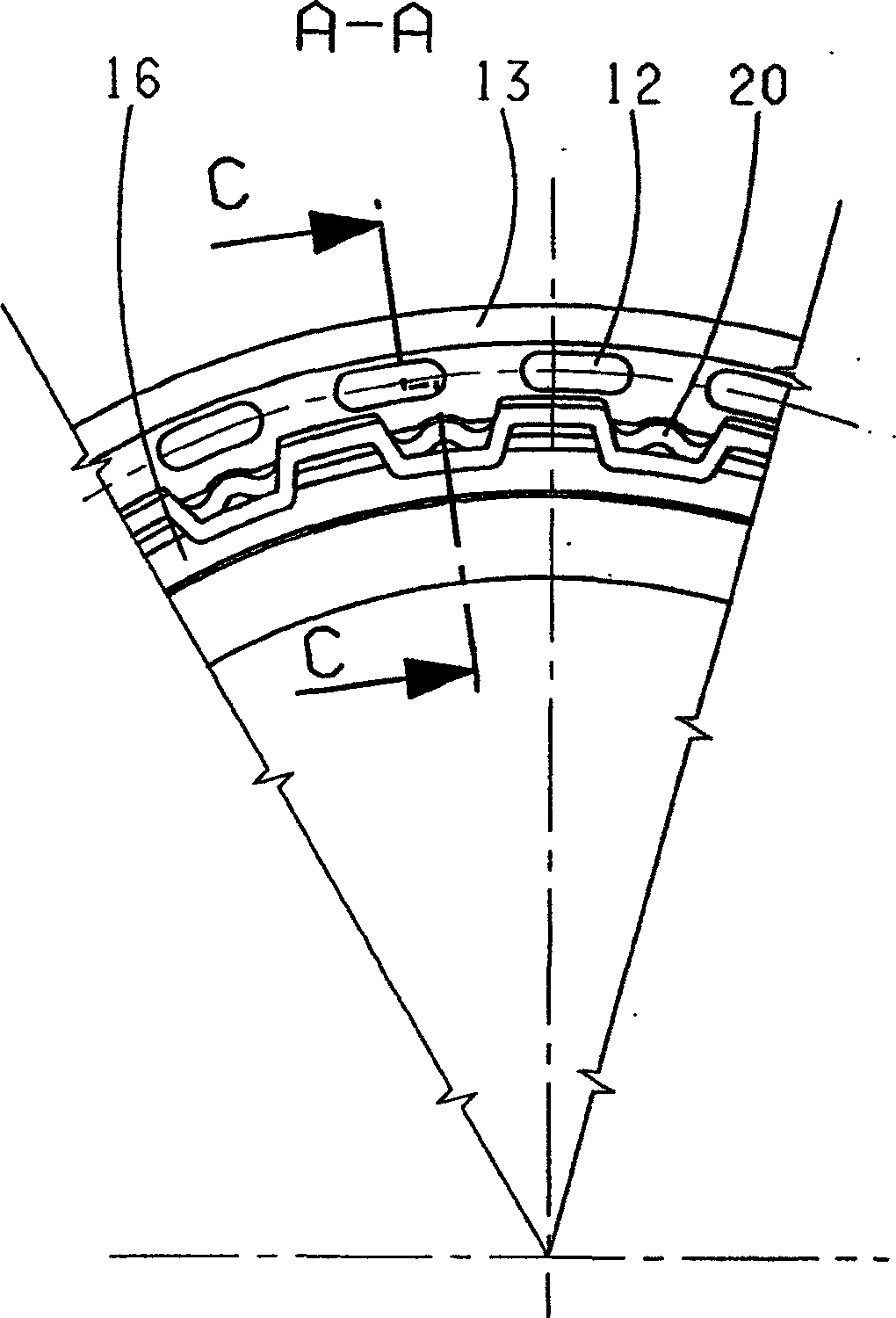

[0028] figure 2 show figure 1 A cross-sectional view of the region A-A in figure 1 Looking in the direction indicated by the two arrows. exist figure 2 The truncation plane C-C shown in the figure 1 Side view of a structural component within the area of the cut line selected in .

[0029] The two disk packs 39, 40, the corresponding outer and inner disk carriers 37, 38 as well as the clutch actuating pistons 10, 17 of the pressure-medium-actuated actuating servo are among the core components of this clutch arrangement, by means of which the Make both clutches close in the same direction of actuation. In this clutch device, the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com