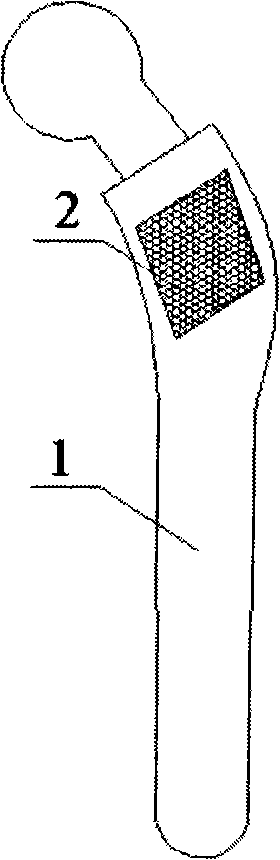

Preparation of artificial joint prosthesis with partially controllable porous structure

A technology of porous structure and artificial joints, applied in the direction of prosthesis, joint implants, joint implants, etc., can solve the problems of mechanical properties of damaged prostheses, and achieve the effect of protecting high-strength mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

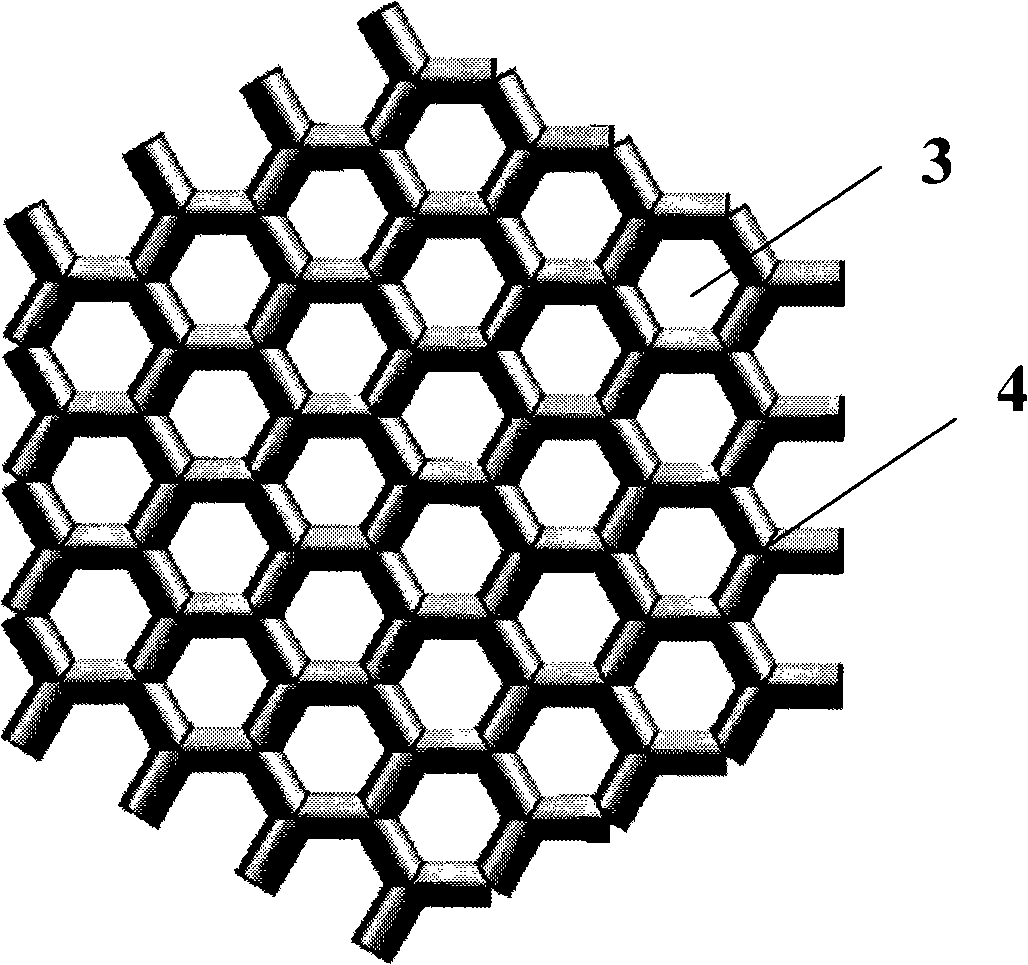

Embodiment 1

[0024] First of all, according to the basic principles that are beneficial to the growth of cells and tissues, the commercial CAD software Unigraphix is used to design a honeycomb porous structure. The pore size is 200 μm, the porosity is 50%, and the pores are completely connected to each other. The designed porous structure The solid CAD model is stored in STL file format; the STL data is input into the rapid prototyping system, and the layered slice processing is performed to obtain the two-dimensional information data of the porous structure; then direct metal rapid prototyping is carried out, and the Ti6Al4V alloy powder is fed by the powder feeding mechanism The powder material is sent to the predetermined area, and the powder spreading mechanism flattens and compacts the powder. Then, the electron beam scans according to the obtained two-dimensional information data under the control of the computer, melts and sinters the powder material, and then feeds the powder and l...

Embodiment 2

[0026] Firstly, according to the basic principle that is conducive to the growth of cells and tissues, the honeycomb porous structure is designed by using the commercial CAD software Unigraphix. The pore size is 600 μm, the porosity is 70%, and the pores are completely connected to each other. The designed porous structure The solid CAD model is stored in STL file format; the STL data is input into the rapid prototyping system, and the layered slice processing is performed to obtain the two-dimensional information data of the porous structure; then direct metal rapid prototyping is carried out, and the Ti6Al4V alloy powder is fed by the powder feeding mechanism Then, the electron beam scans according to the obtained two-dimensional information data under the control of the computer, melts and sinters the powder material, and then feeds the powder and lays the powder. powder, melting and sintering powder, and repeat this process until the entire test piece is formed. The basic p...

Embodiment 3

[0028]Firstly, according to the basic principle that is conducive to the growth of cells and tissues, the honeycomb porous structure is designed by using the commercial CAD software Unigraphix. The pore size is 1000 μm, the porosity is 90%, and the pores are completely connected to each other. The designed porous structure The solid CAD model is stored in STL file format; the STL data is input into the rapid prototyping system, and the layered slice processing is performed to obtain the two-dimensional information data of the porous structure; then direct metal rapid prototyping is carried out, and the Ti6Al4V alloy powder is fed by the powder feeding mechanism The powder material is sent to the predetermined area, and the powder spreading mechanism flattens and compacts the powder. Then, the electron beam scans according to the obtained two-dimensional information data under the control of the computer, melts and sinters the powder material, and then feeds the powder and lays t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com