Measuring and machining integrated laser three-dimensional marking method and device

A laser three-dimensional, laser technology, used in typewriters, printing, digital control and other directions to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

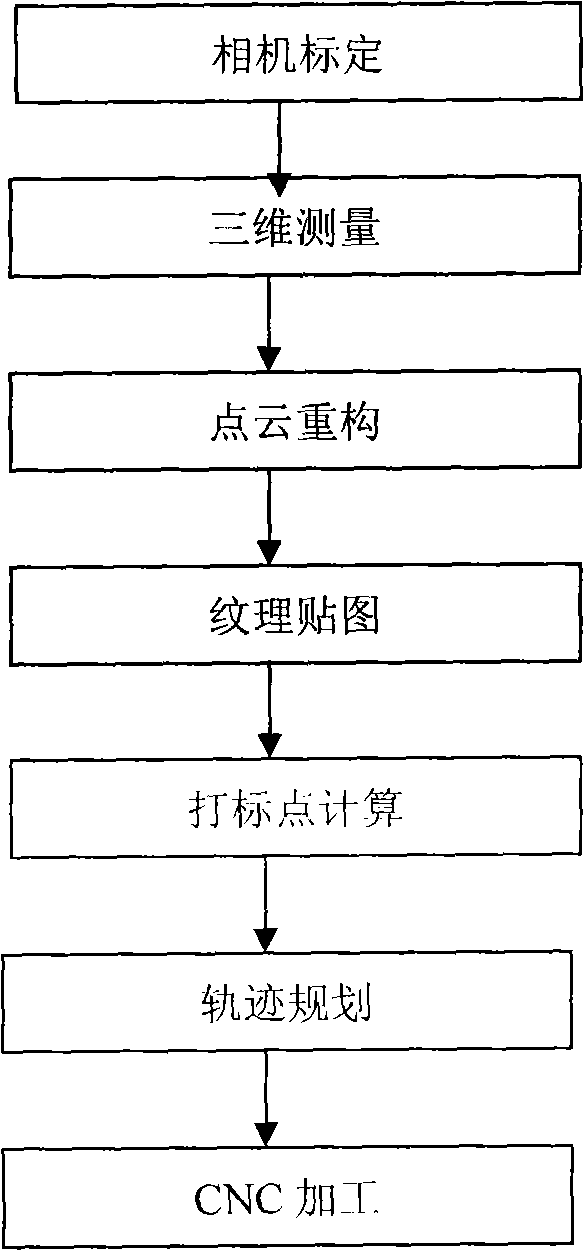

[0027] 1. The overall process flow

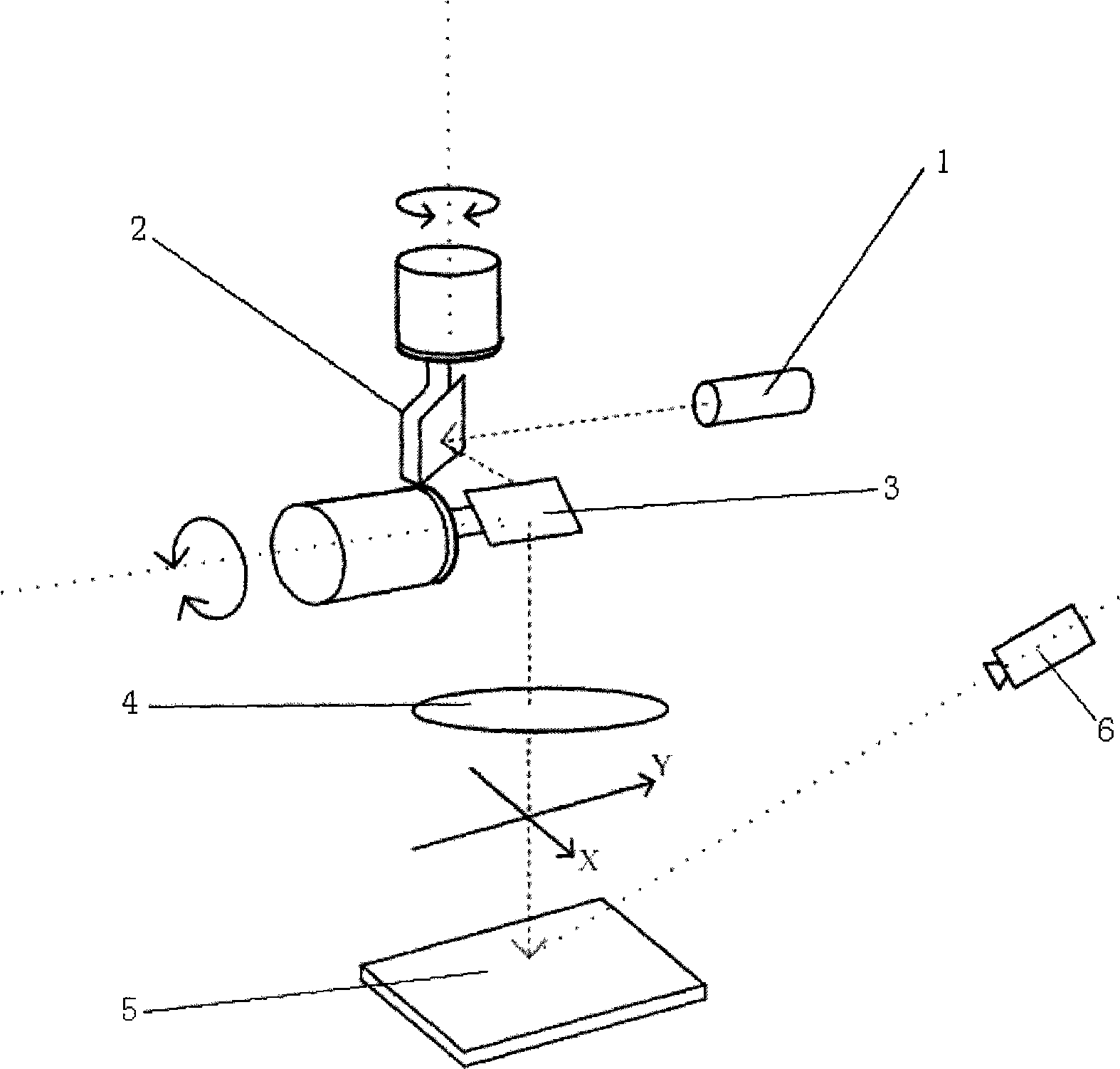

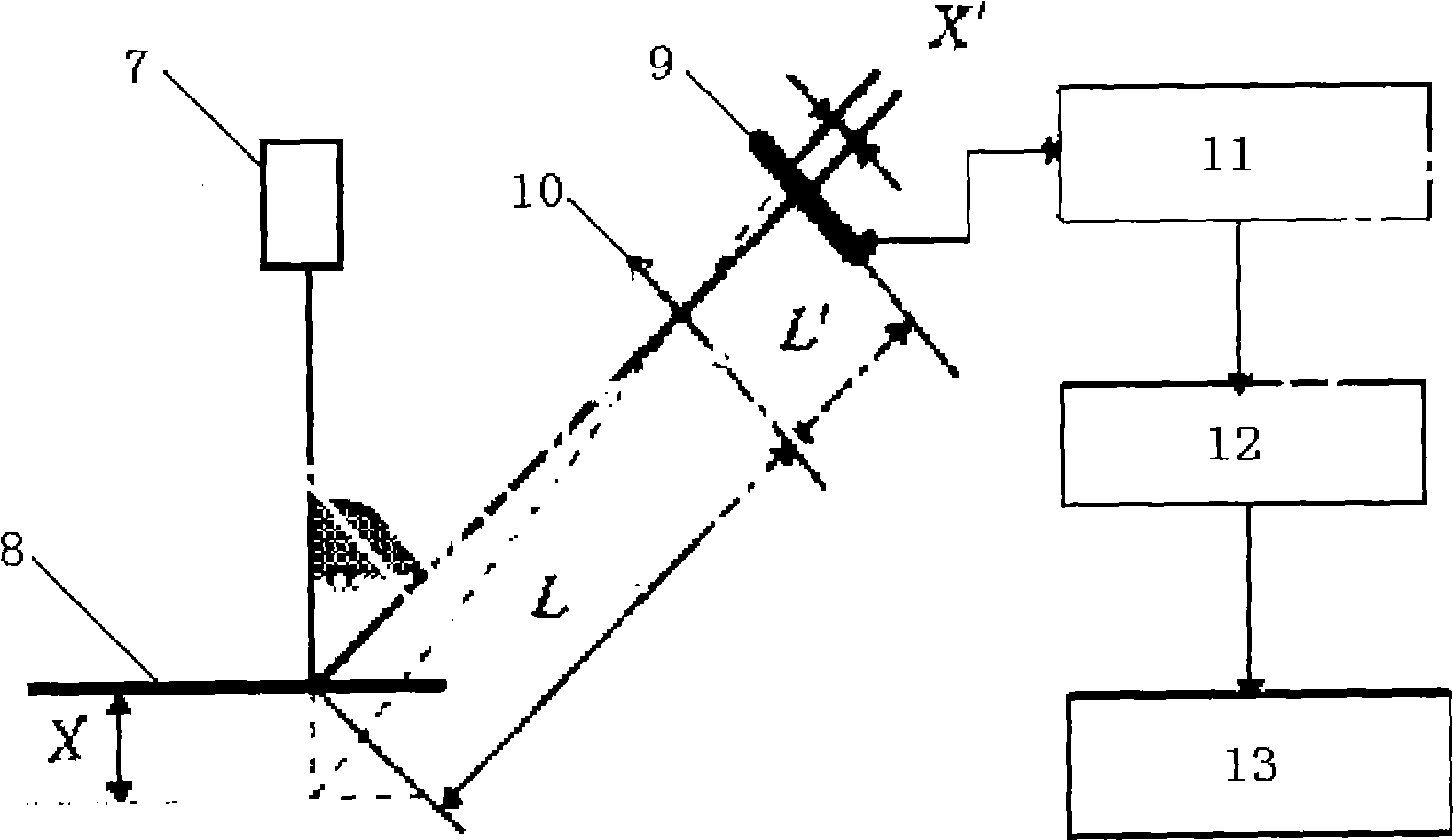

[0028] The following will combine figure 1 The overall technological process of the present invention is described. After the optical camera is installed and fixed, the camera must be calibrated to obtain the positional relationship data between the camera and the workbench of the engraving machine. The present invention can use the calibration algorithm of the single-point laser displacement meter. The algorithm is the classic laser triangulation method.

[0029] After the calibration is completed, after the target part is fixed on the workbench, enter the three-dimensional measurement step, control the laser to scan at a fixed point at a lower power at this time, and obtain a series of collected images, from the collected images through the image processing algorithm, automatically find the For the center of the light spot, the depth information of the light spot can be measured according to the displacement of the light spot combined wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com