Remote 3D printing method and system

A 3D printing, remote technology, applied in the field of 3D printing, can solve the problems that cannot fully meet the needs of 3D printing remote real-time printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

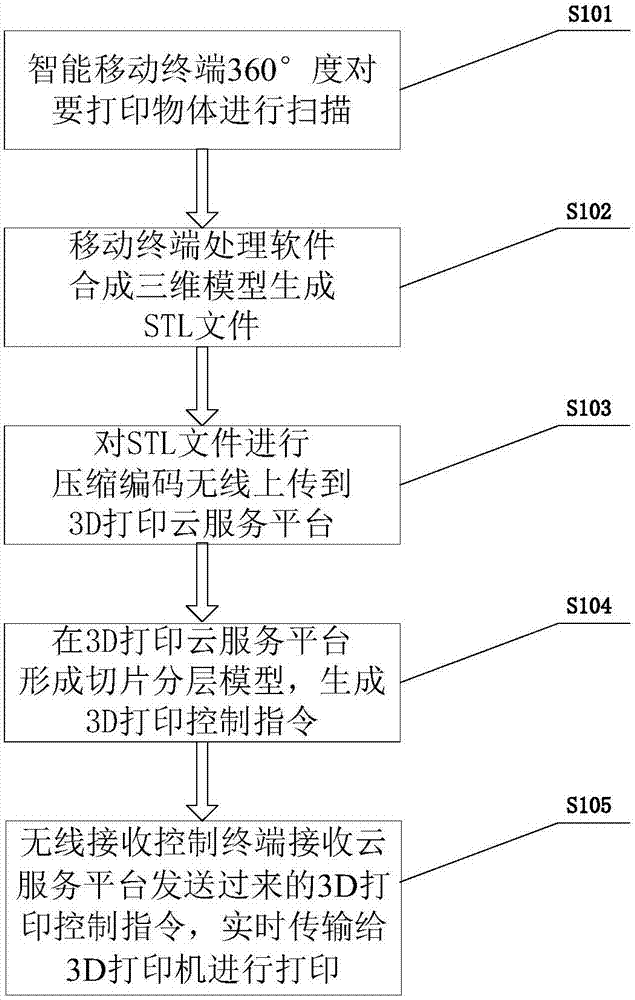

[0023] figure 1 A remote 3D printing method provided by the present invention specifically includes the following steps:

[0024] S101. Use the camera and camera functions of the smart mobile terminal (smart phone, tablet computer) as the scanning function to scan the object to be printed at 360° to obtain a scanned file of the object.

[0025] When scanning the object to be printed, you can choose an angle to start, and scan all angles of the object and the details of the protruding and concave parts of the object to obtain the scanned file of the object.

[0026] S102. Synthesize the scanned files into a 3D model of the object to be printed through the 3D modeling processing software provided by the smart mobile terminal, and perform triangular mesh faceting on the model to generate an STL (standard template library) file. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com