Dental implant and preparation method thereof

A technology of dental implants and implants, applied in dentistry, dental implants, dental restorations, etc., can solve problems such as poor bonding strength, and achieve the effect of firm connection, improved bonding strength, and perfect connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

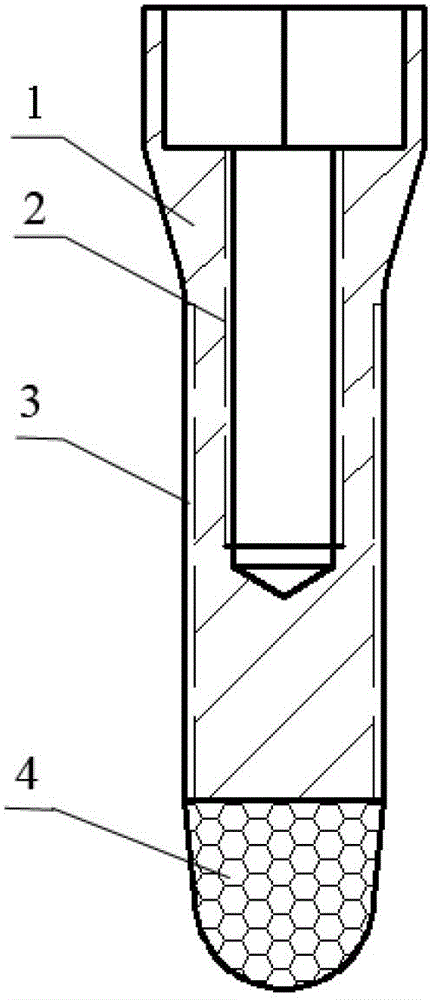

[0020] The preparation method of novel porous structure dental implant of the present invention comprises the following steps:

[0021] The first step is to use known commercial CAD software, such as: Unigraphix, Pro / E, Catia, etc., to design the overall structure of the dental implant, and to design the porous structure according to the principle of facilitating the growth of cells and tissues 4 The structure: the pores are completely connected to each other, the pore size is designed to be 300-1000 microns, the porosity is designed to be 60%-90%, and the CAD design data of the dental implant with a porous structure at the bottom is stored as STL file format.

[0022] In the second step, the CAD model design data of the above-mentioned dental implant is input into the rapid prototyping system, which is mainly used to control the scanning path of the electron beam, and the materialize's Magics software in the system is used to analyze the dental implant. Carry out layered sli...

Embodiment 1

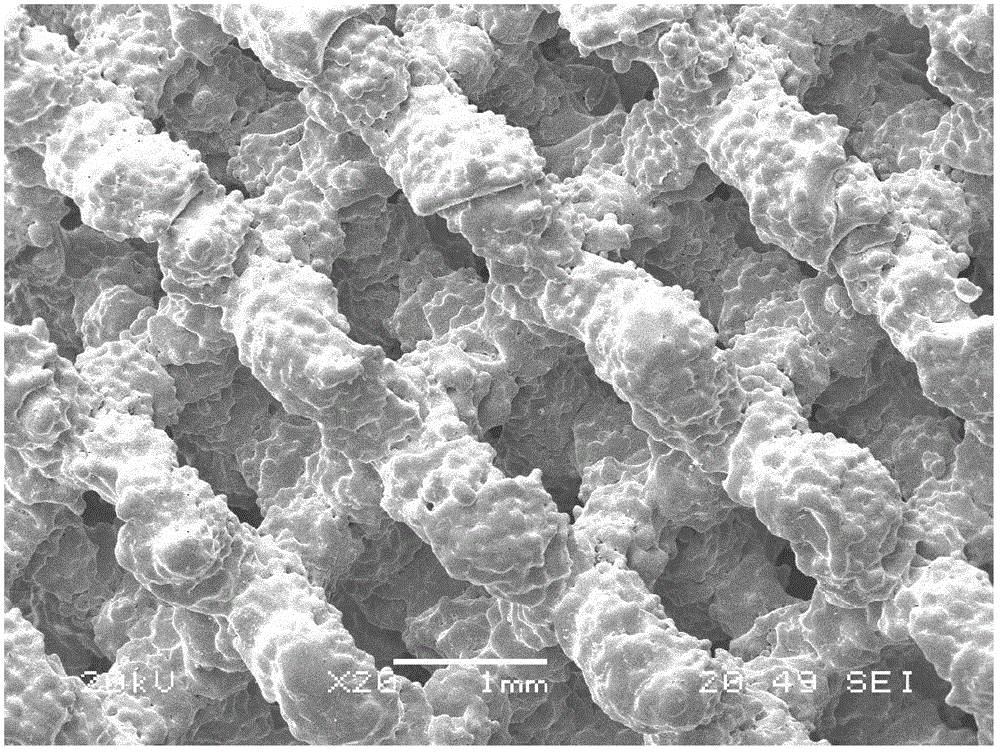

[0029] First, use the well-known commercial CAD software Unigraphix to design the overall structure of the dental implant, and then design a diamond molecular structure porous structure 4 at the end of the implant according to the basic principles that are conducive to the growth of cells and tissues. The pore size is 300 microns. The porosity is 60%, and the pores are completely connected to each other. The CAD design data of the designed porous structure is stored in the STL file format; the STL data is input into the rapid prototyping system, and the layered slice processing is performed to obtain the two-dimensional dental implant. Information data; then direct metal rapid prototyping is carried out, the Ti metal powder material is sent to the predetermined area by the powder feeding mechanism, the powder spreading mechanism flattens and compacts the powder, and then, the electron beam is controlled by the computer according to the obtained Scan the two-dimensional informat...

Embodiment 2

[0031]First, use the commercial CAD software Pro / E to design the overall structure of the dental implant, and then design a porous structure 4 with a diamond molecular structure at the bottom of the implant according to the basic principles that are conducive to the growth of cells and tissues. The pore size is 650 micron, the porosity is 75%, and the pores are completely connected to each other. The designed CAD model of the dental implant is stored in the STL file format; the STL data is input into the rapid prototyping system, and the layered slice processing is performed to obtain the second image of the dental implant. Dimensional information data; then directly carry out metal rapid prototyping manufacturing, the cobalt-chromium-molybdenum alloy powder material is sent to the predetermined area by the powder feeding mechanism, and the powder spreading mechanism flattens and compacts the powder, and then, the electron beam is controlled by the computer according to Scan th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com