Systems and methods enabling zoned electrospinning of multiple materials

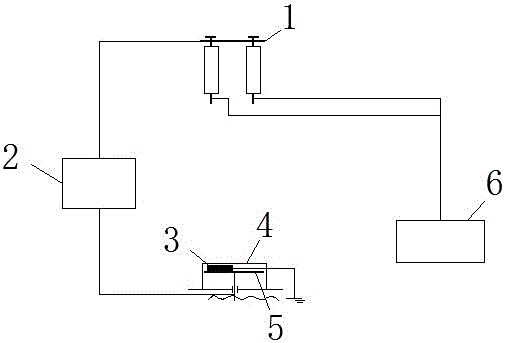

A multi-material, electrospinning technology, applied in the fields of electrospinning and biomanufacturing, can solve the problems of uncontrollable receiving fibers and restricting the application of electrospinning technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

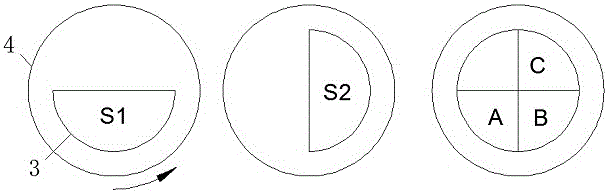

[0026] Such as figure 2 As shown, the method (embodiment 1) of the present invention that can realize multi-material partition electrospinning comprises the following steps:

[0027] 1) Prepare two 8.8% PVA (polyvinyl alcohol) solutions, both 20ml;

[0028] 2) Take the second-generation human adipose stem cells and centrifuge them at 1000r / min for 5min to prepare a cell content of 4X10 6 cells / ml cell suspension; take the second-generation human fibroblasts and centrifuge at 1000r / min for 5min to prepare a cell content of 4X10 6 cell suspension per ml;

[0029] 3) Mix 5ml of adipose stem cells with a portion of PVA, stir evenly, and put it into the barrel m; put a portion of the PVA solution into the outer channel of the barrel n, and put 5ml of the cell suspension into the barrel n in the inner channel;

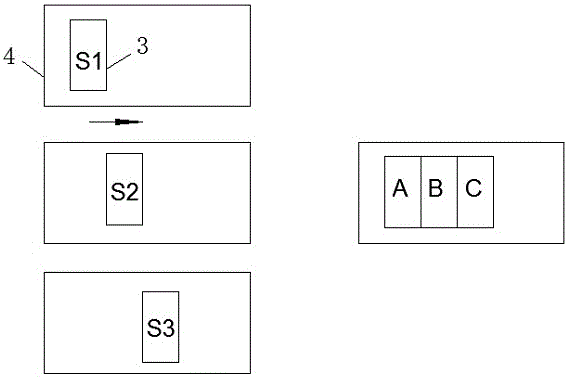

[0030] 4) When the conductor is located figure 2 At the position S1, the micropump of the feeding mechanism controls the supply of the electrospinning solution, and t...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, and the special features are as follows: the double nozzles are expanded into three nozzles, and the three nozzles all adopt coaxial nozzles, including the following steps:

[0038] 1) Prepare three 8.8% PVA solutions, each 20ml;

[0039] 2) Prepare solutions of vascular endothelial growth factor (VEGF), fibroblast growth factor (bFGF), and epidermal growth factor (EGF) at a concentration of 2%;

[0040] 3) Put a portion of PVA into the outer channel of the barrel m of the multi-nozzle feeding mechanism, and put a solution of vascular endothelial growth factor (VEGF) into the inner channel of the barrel m of the multi-nozzle feeding mechanism; One part of PVA is loaded into the outer channel of the barrel n of the multi-nozzle feeding mechanism, and the fibroblast growth factor (bFGF) solution is loaded into the inner channel of the barrel n of the multi-nozzle feeding mechanism; one part of PVA Put it into the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com