Resin composition for temperature control indication

A resin composition and indicating technology, applied in the field of resin composition for temperature control indication, can solve the problems of limiting the application range of thermochromic pigments, residual background color, poor temperature resistance, etc., achieving repeatability and widening temperature range. , the effect of huge market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

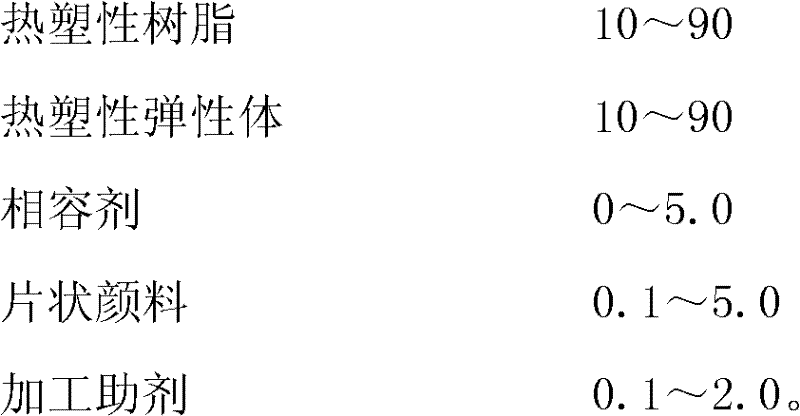

[0036] Prepare materials according to the following components and parts by weight:

[0037]

[0038] Among them, the thermoplastic resin is PP;

[0039] The thermoplastic elastomer is EPR;

[0040] The flake pigment is bismuth oxide coated pearlescent pigment, with a particle size of 20-200 μm;

[0041] The processing aid is Ciba Specialty Antioxidant B9000.3, the lubricant is zinc stearate 0.5, and the light stabilizer is Ciba Specialty UVP (hydroxybenzotriazole) and 770 (hindered amine) 0.1 each.

[0042] To accentuate the difference in color, some red organic dye is added.

Embodiment 2

[0044] Prepare materials according to the following components and parts by weight:

[0045]

[0046]

[0047] Wherein, thermoplastic resin is PVC;

[0048] The thermoplastic elastomer is EPR;

[0049] The flake pigments are mica-based pearlescent pigments with a particle size of 200-500 μm;

[0050] The processing aid is Ciba Specialty Chemical Antioxidant B9000.3, the lubricant is magnesium stearate 1.0, and the light stabilizer is Ciba Specialty Chemical UVP, 0.1 each of 770. To accentuate the difference in color, some red organic dye is added.

Embodiment 3

[0052] The component ingredients are the same as in Example 2, only on the basis of Example 2, the flake pigments are changed from mica-based pearlescent pigments to flake aluminum powder pigments with a particle size of 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com