Method and system for adaptively controlling a laser-based material processing process and method and system for qualifying same

a laser-based material and processing process technology, applied in the laser field, can solve problems such as limit yield, and achieve the effect of eliminating unnecessary test steps in device fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0085] Unless otherwise stated the phrase “semiconductive workpiece” or terms “workpiece” or “substrate” are to be non-limiting, and are to be construed as a workpiece having a semiconductor material. By way of example, a workpiece may be a semiconductor wafer with a plurality of die thereon, and may generally include multi-material devices. Memory circuits fabricated on silicon substrates are one example, and are generally constructed as a series of layers on a silicon wafer as taught in LIA HANDBOOK (referenced above), U.S. Pat. Nos. 5,936,296; 6,320,243; and 6,518,140, and numerous other patents and publications. The workpiece may be an entire substrate (e.g., 200 mm diameter wafer) with a large number of die, singulated die or devices, device portions, or other variations of semiconductor devices or chips which may repaired with a laser.

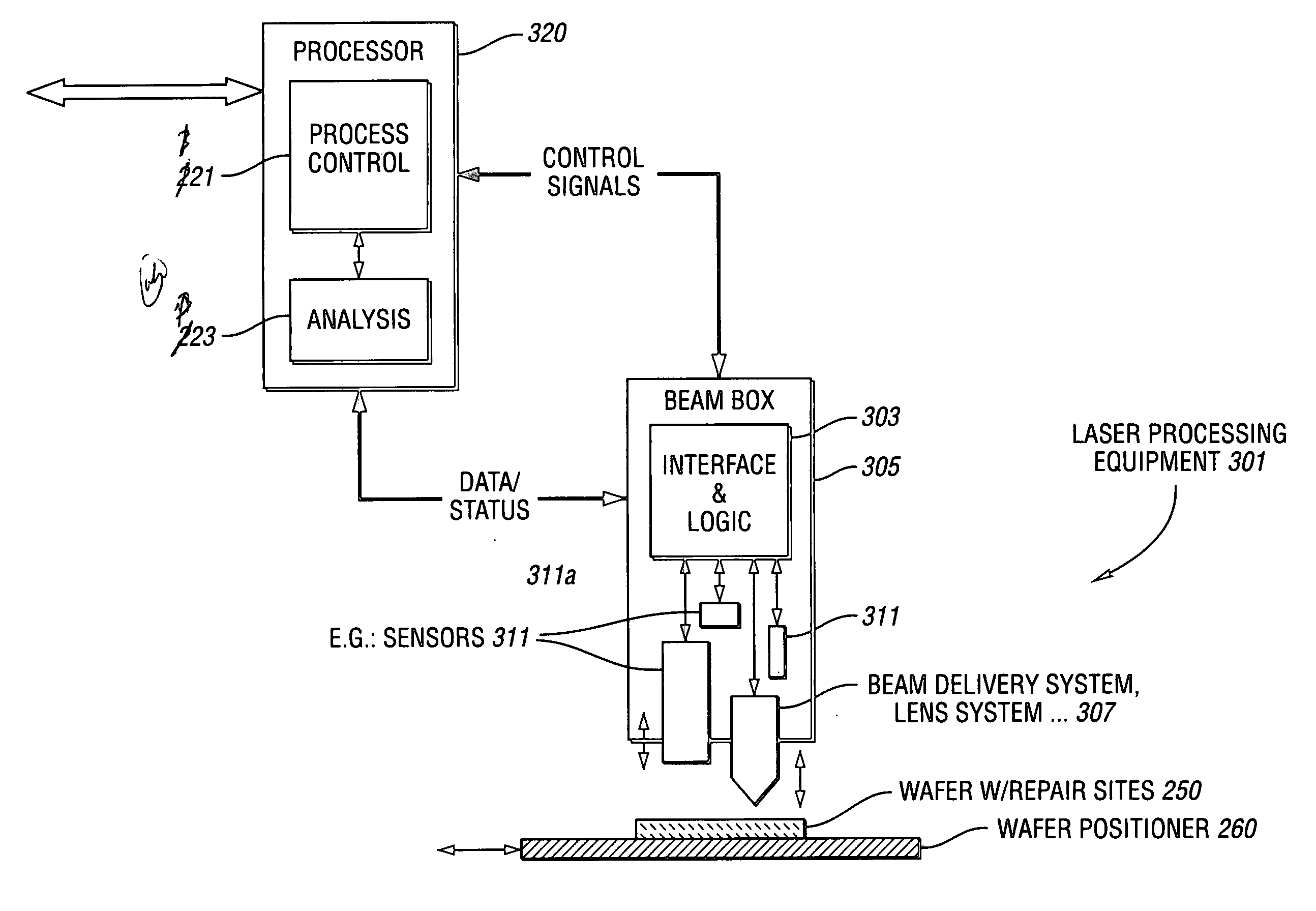

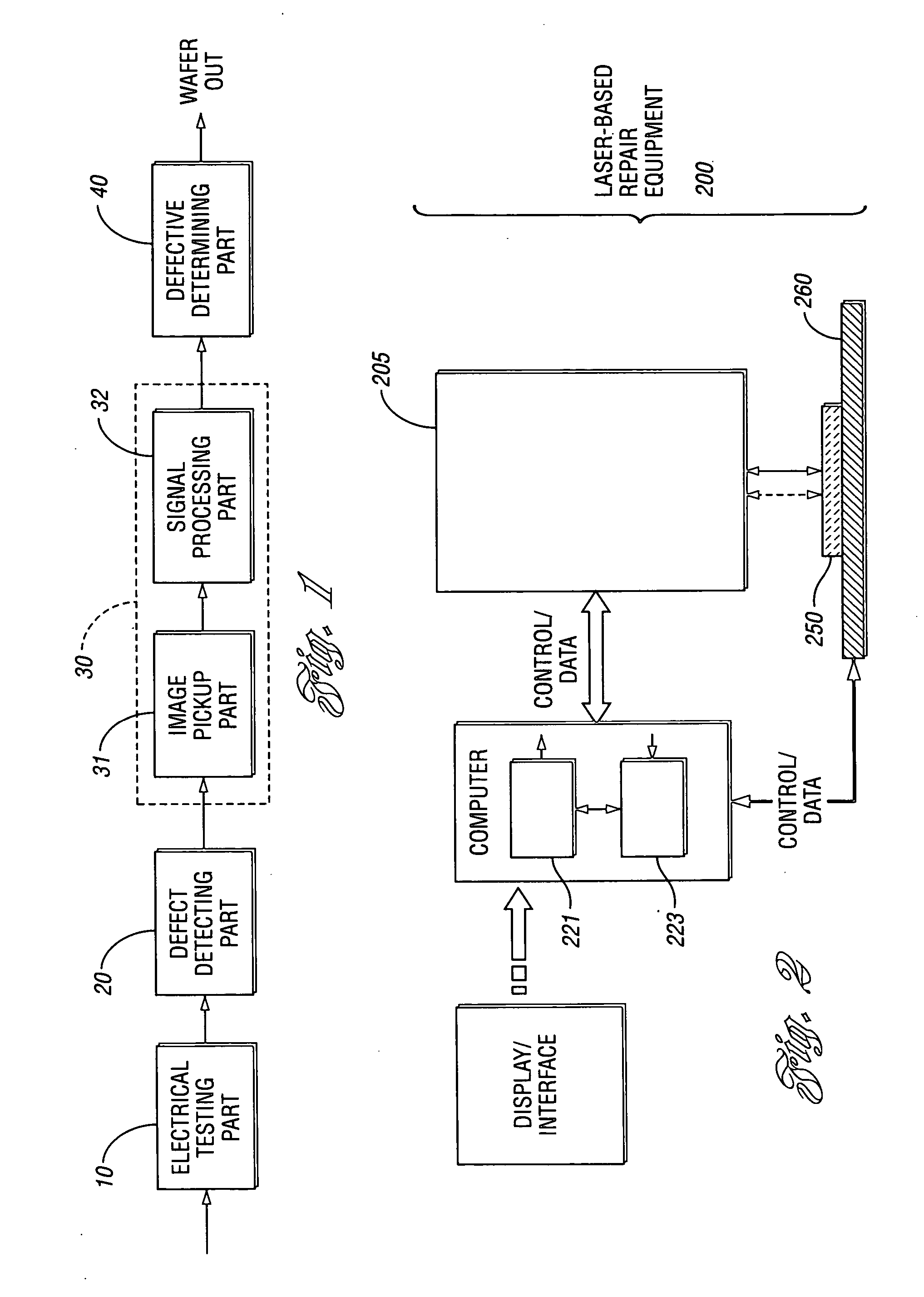

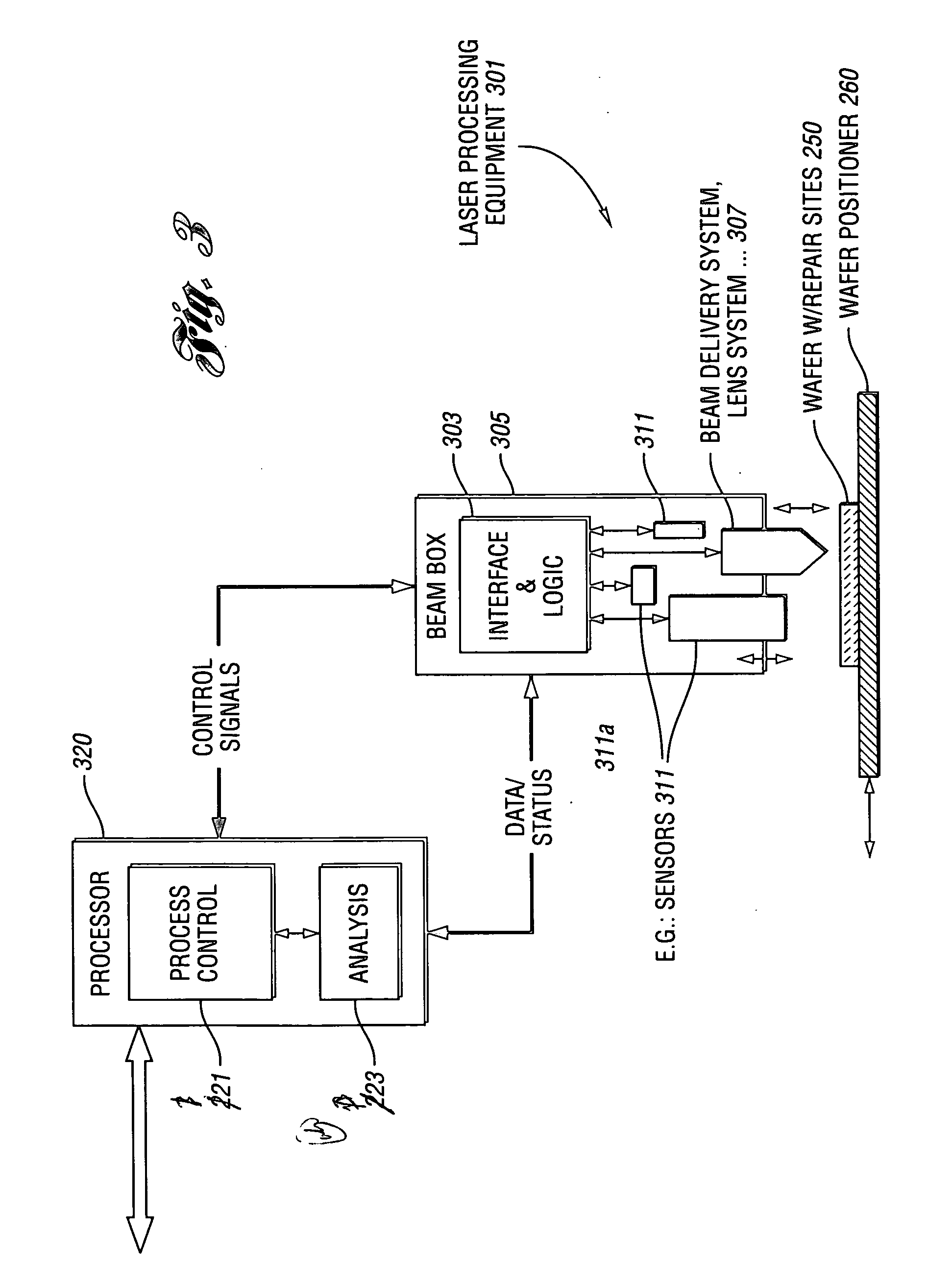

[0086]FIG. 2 shows some elements of a general embodiment of the present invention. The laser-based repair system 200 generally includes laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com