Catalytically cracked gasoline deep desulfurization combined technique

A catalytic cracking gasoline, deep desulfurization technology, applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of large octane loss, desulfurization rate decline, low product liquid yield, etc., to achieve high desulfurization depth , mature catalyst and high liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

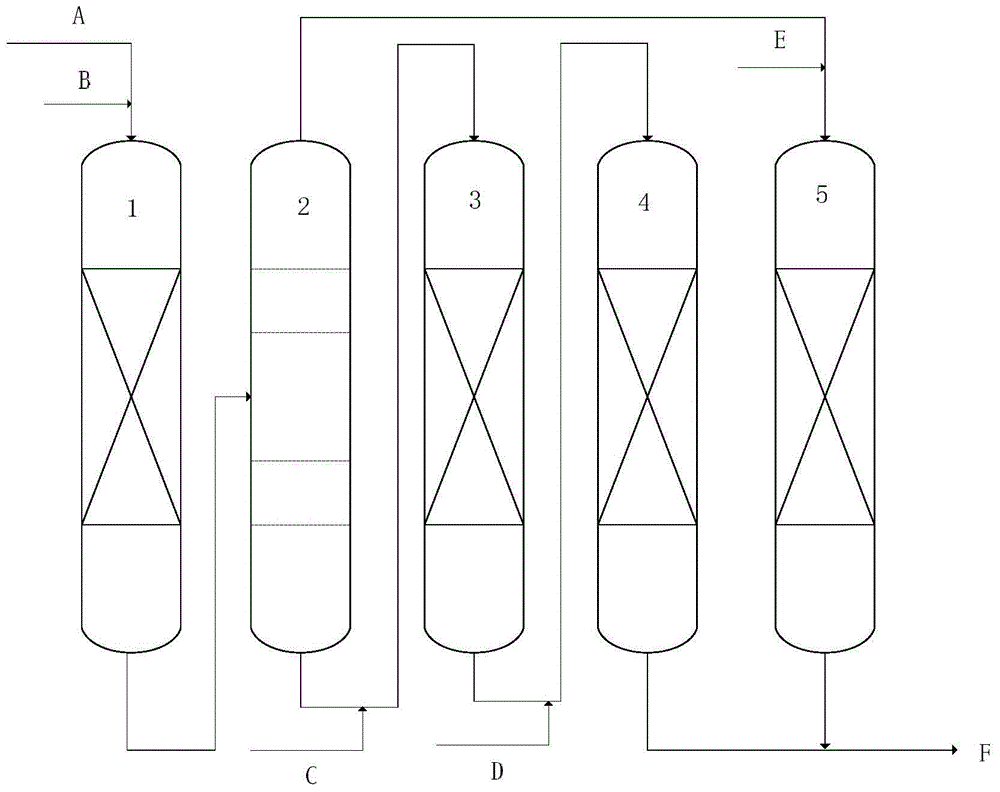

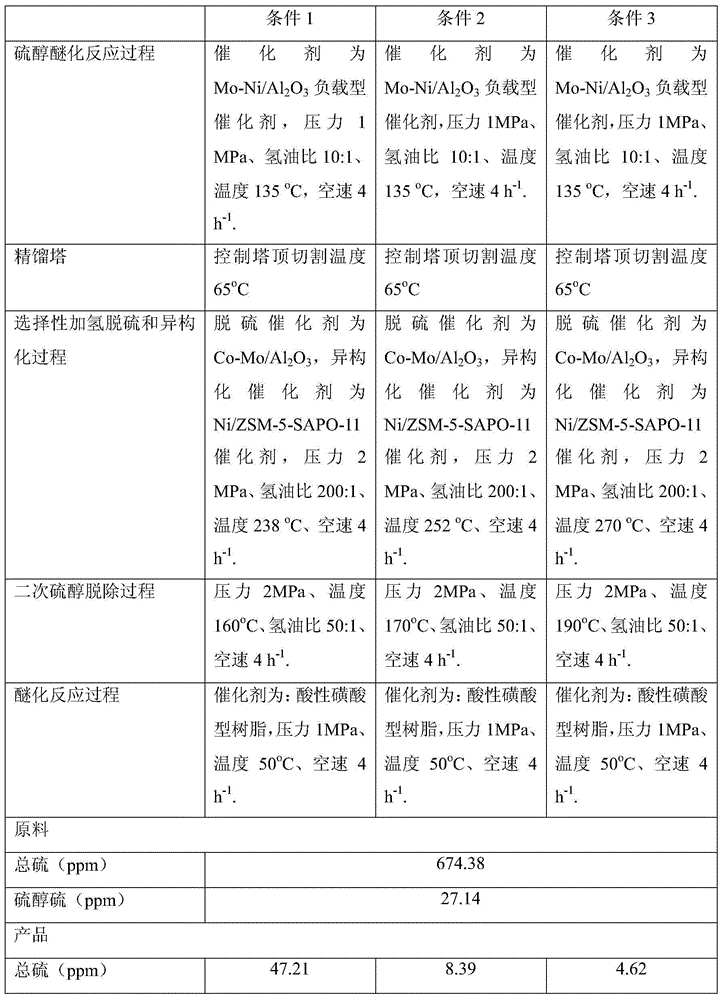

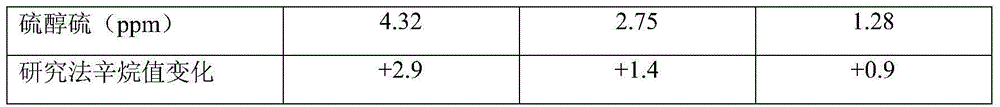

[0032] The whole-fraction catalytic cracking stable gasoline raw material A is mixed with hydrogen B, and then enters the fixed-bed reactor 1 filled with mercaptan etherification reaction catalyst, at a reaction pressure of 0.5-3.5MPa, a temperature of 60-180°C, and a space velocity of 1-10h -1, Under the condition of hydrogen-to-oil volume ratio of 0.5-20, the thioetherification reaction between mercaptans and olefins or diolefins occurs, and the mercaptans are converted into heavy sulfides, while the diolefins are selectively hydrogenated into monoolefins. After the reaction, the gasoline enters a rectification tower to cut the whole distillate gasoline into light and heavy parts, wherein the cutting point temperature is 65°C, and the top of the tower is the olefin-rich and sulfur-free light gasoline component. The heavy distillate at the bottom of the tower is mixed with hydrogen C and then enters the selective hydrogenation reactor. The reaction pressure is 0.5-3.5MPa, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com