Method for treating organic wastewater by photoelectric combined technique

A technology for organic wastewater and technical treatment, which is applied in illumination water/sewage treatment, electrochemical water/sewage treatment, multi-stage water treatment, etc. It can solve the problems of incomplete degradation, large investment in reactor construction, and incomplete reaction. Achieve the effect of easy industrial scale-up application, good COD removal rate, and complete wastewater degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

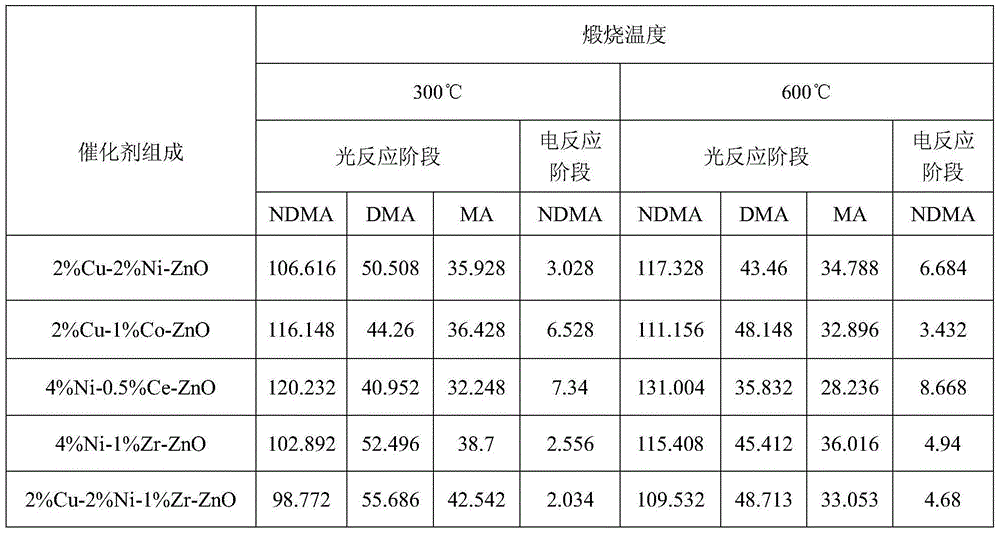

Examples

preparation example Construction

[0015] The preparation method of the three-dimensional electrode material used in the electric reaction stage is as follows: the main anode is a boron-doped diamond film electrode, the main cathode is stainless steel (can be made into a drum), and the electrode material filled with particles is carbon nanofibers and calcium alginate microspheres. 5-20g / L, cell voltage 8-12V, initial pH value 6.0-7.5, treatment time 20-60min. Among them, the preparation method of the main anode-boron-doped diamond film electrode is as follows: choose diamond powder, mechanically grind on the surface of the substrate material to form scratch damage, and then use acetone solution to ultrasonically clean it for standby; use acetone as the carbon source, hydrogen as the etching gas, Boron trioxide (B 2 o 3 ) as the dopant source, the main anode boron-doped diamond film electrode material is prepared by hot wire chemical vapor deposition (HFCVD); the base material mainly includes one or more of p-t...

Embodiment 1

[0020] Embodiment 1: Unsymmetrical dimethylhydrazine wastewater treatment

[0021] At room temperature 35°C, add 1.0 g of 4% CuO-4% ZrO 2 -ZnO (molar ratio) modified nano-zinc oxide catalyst, add 10mL 30% hydrogen peroxide to enhance the generation of OH, put the mixed solution in a dark place, stir and mix well, put it under a UV lamp for photocatalytic degradation for 30min, take out A certain amount of treatment liquid is subjected to concentration measurement. After photocatalytic degradation, the concentration of unsymmetrical dimethylhydrazine was 68.5mg / L, the removal rate was 86.3%, the COD was 204.7mg / L, the removal rate was 79.4%, and the intermediate product NH 3 -N content is 35 mg / L, and nitrosodimethylamine NDMA content is 14.3 mg / L. Then the light-treated wastewater is transferred to an electrochemical device, the main anode is a boron-doped diamond film electrode, the main cathode is a drum made of stainless steel, and the filling material is 10g / L carbon nan...

Embodiment 2

[0022] Embodiment 2: aniline wastewater treatment

[0023] Add 0.4g of 2%CuO-0.5%ZrO to 100mL of aniline wastewater with an initial concentration of 450mg / L and an initial COD of 991mg / L at a room temperature of 18°C 2 -ZnO (molar ratio) modified nano-zinc oxide catalyst and 10mL of 30% hydrogen peroxide, the mixed solution was placed in a dark place and stirred evenly, then photocatalytic degradation was carried out under an ultraviolet lamp for 60min, and a certain amount of the treatment solution was taken out for concentration determination. After photocatalytic degradation, the concentration of aniline was 136.2mg / L, the removal rate was 69.7%, and the COD was 343.9mg / L, the removal rate was 65.3%. Then the light-treated wastewater is transferred to the electrochemical device, the main anode is a boron-doped diamond film electrode, the main cathode is stainless steel, the filling material is 5g / L carbon nanofiber and 20g / L calcium alginate microspheres, and the cell volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com