Combined technique for processing heavy oil

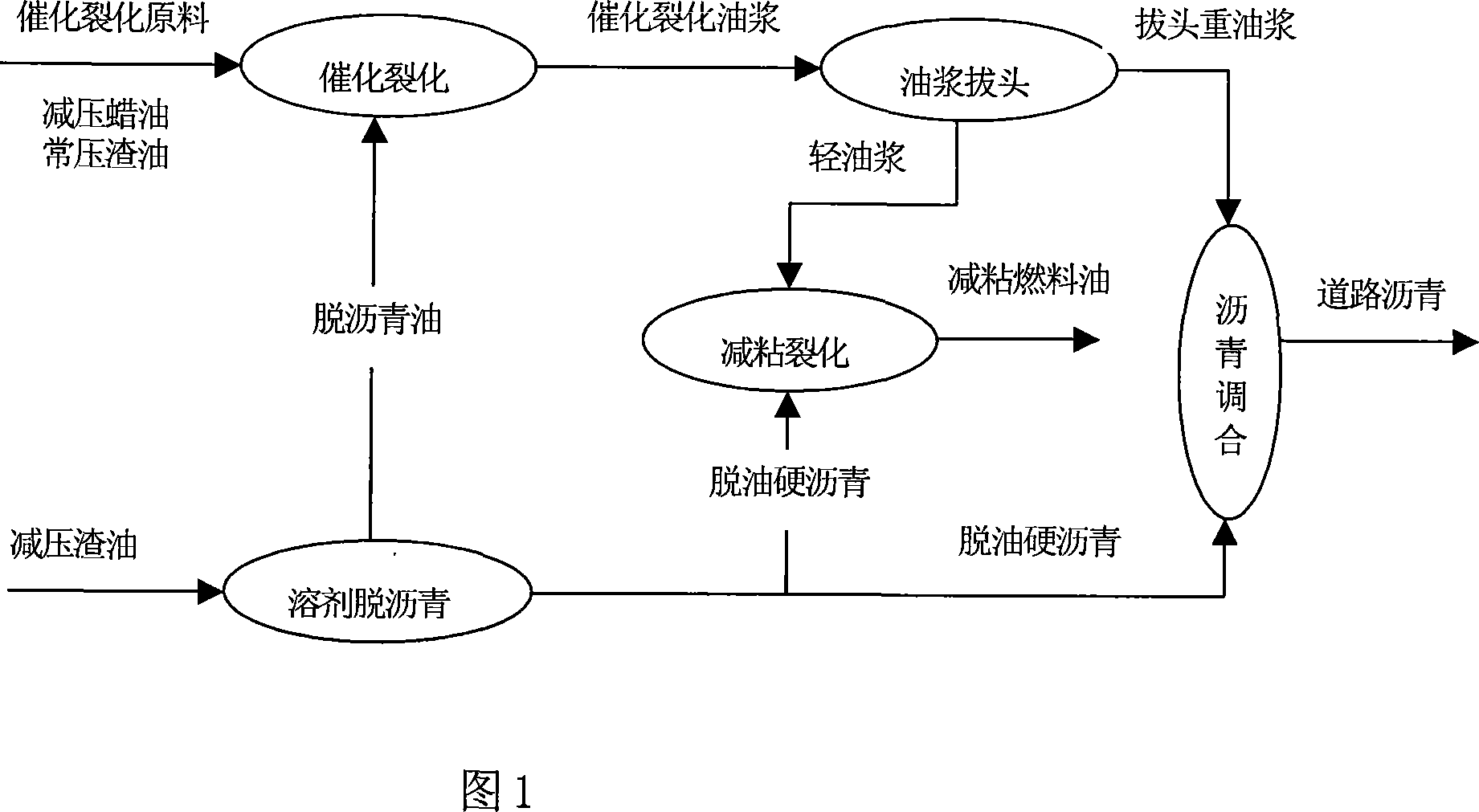

A combined process, heavy oil technology, applied in the direction of selective solvent extraction tar processing, only multi-stage series refining and cracking process treatment, etc., to achieve the effect of reducing wax content, improving quality and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

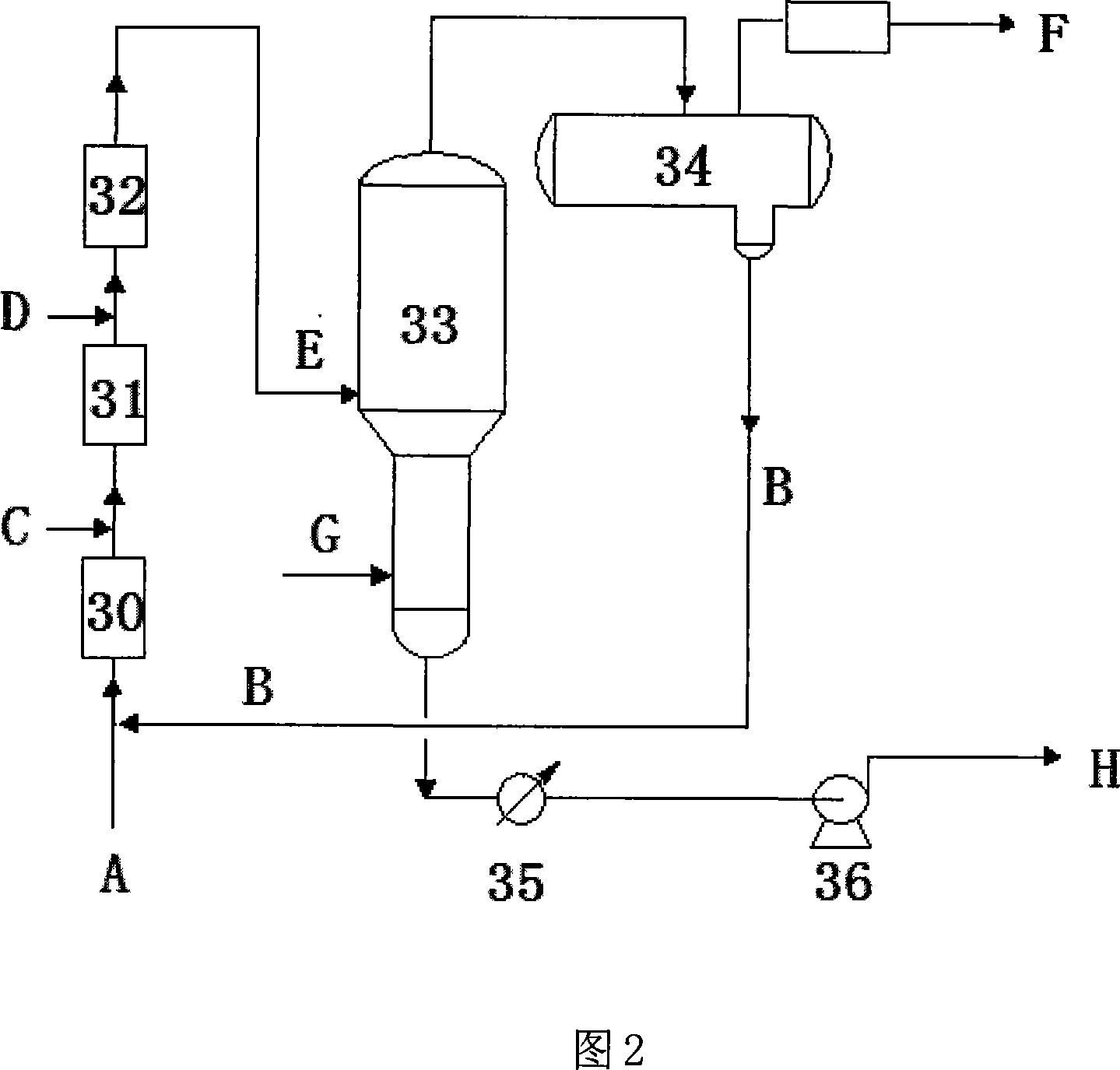

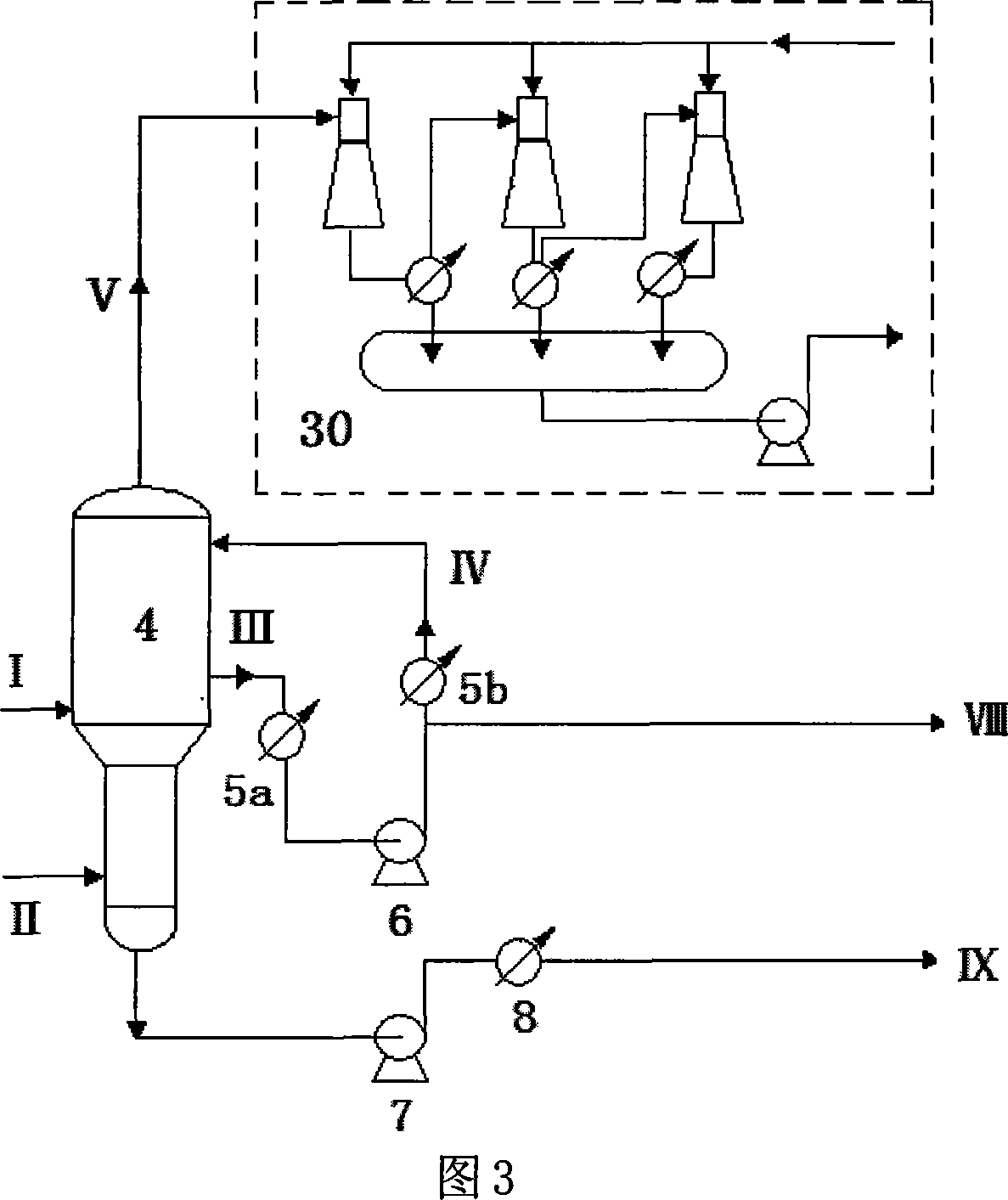

[0060] Solvent deasphalting process: blending the mixed vacuum residue A of Zhongyuan crude oil (paraffin base) and Oman crude oil (intermediate base) with a blending ratio of 30:70 (by weight), first with the circulating gum B from the bottom of the gum settler Mix in primary mixer 31, then mix in secondary mixer 32 with dilute solvent butane C that accounts for 16% of total solvent weight, then mix with main solvent D that accounts for 70% of total solvent weight in tertiary mixer 33 After mixing in the medium, enter the asphaltene extractor 34 for liquid phase extraction and sedimentation separation, and use the temperature control valve to control the temperature at 115 ° C; the stream drawn from the top of the extractor enters the deasphalted oil desolvent treatment unit 37, The deasphalted oil F is obtained after the solvent butane is separated by flash evaporation and stripping. In order to make the extraction more thorough, inject from the bottom of the asphaltenes ext...

Embodiment 3

[0080] Solvent deasphalting process: blending the mixed vacuum residue A of Zhongyuan crude oil (paraffin base) and Oman crude oil (intermediate base) with a blending ratio of 40:60 (by weight), first with the circulating gum B from the bottom of the gum settler Mix in primary mixer 31, then mix in secondary mixer 32 with dilute solvent butane C that accounts for 8% of total solvent weight, and then mix with main solvent D that accounts for 80% of total solvent weight in tertiary mixer 33 After mixing in the medium, enter the asphaltene extractor 34 for liquid phase extraction and sedimentation separation, and use the temperature control valve to control the temperature at 112 ° C; the stream drawn from the top of the extractor enters the deasphalted oil desolvent treatment unit 37, The deasphalted oil F is obtained after the solvent butane is separated by flash evaporation and stripping. In order to make the extraction more thorough, inject the secondary solvent butane G acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com