Combined technique for preparing olefins by using refinery C4

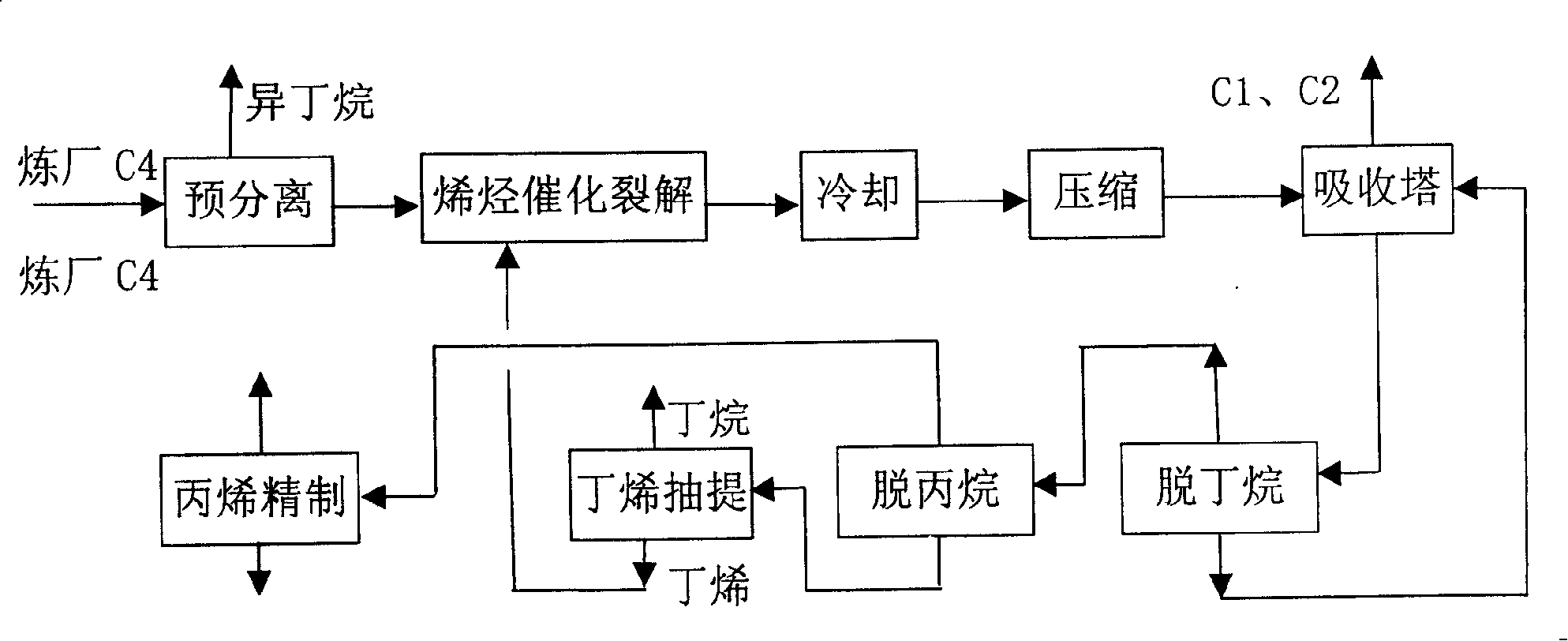

A combination process, C4 technology of refinery, applied in the field of new process of producing and separating olefins, can solve the problem of low utilization rate of C4 in refinery, achieve significant industrial value, reduce production cost, and increase production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

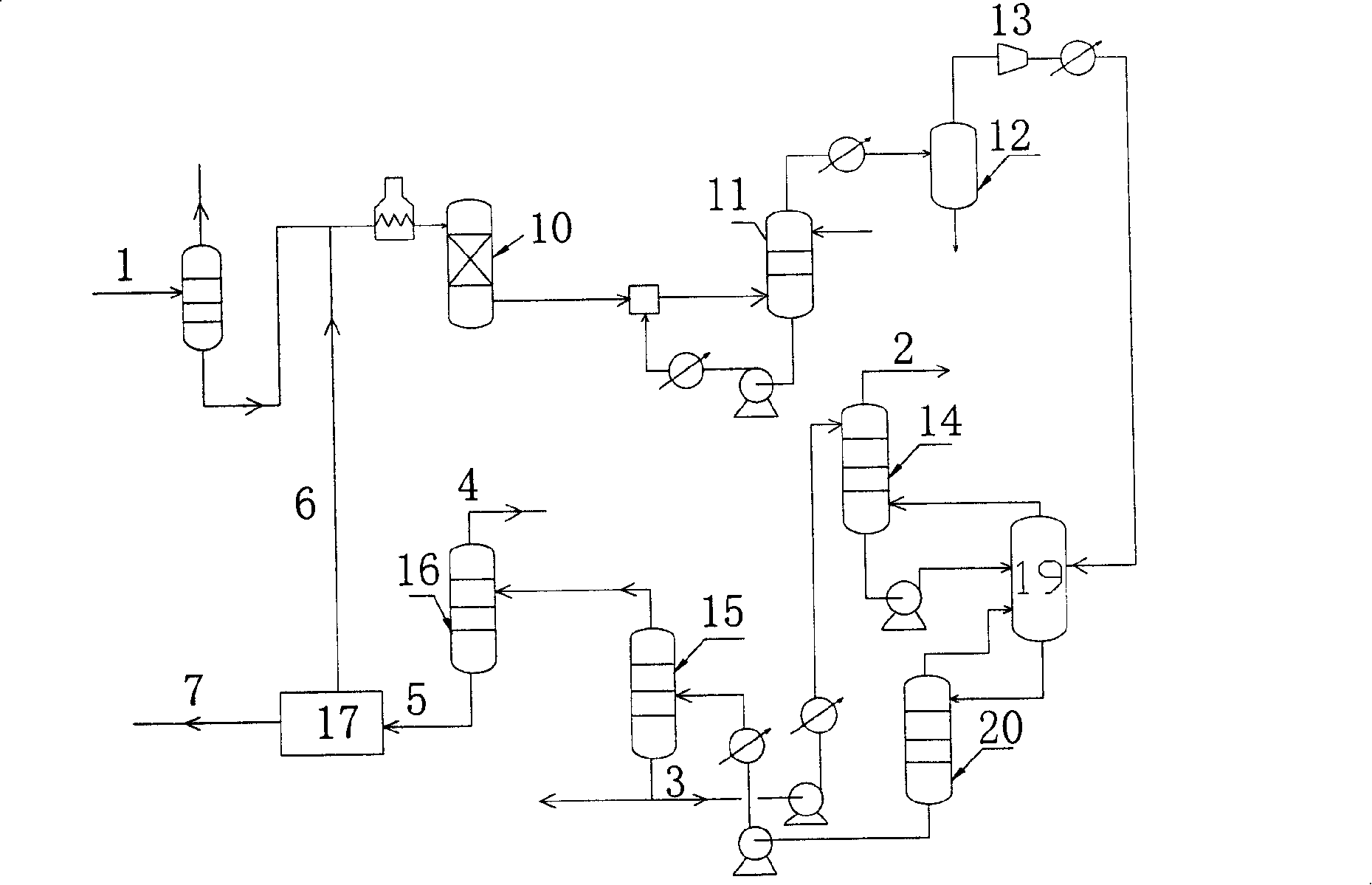

[0043] Reference attached figure 2 , with the flow rate of 17500kg / h refinery C41 as raw material, its main composition (mass percentage) is: propane 7.3%, isobutene 14.0%, 1-butene 14.0%, cis-2-butene 16.3%, trans 20.2% -2-butene, 17.0% n-butane, 0.5-10.0% isobutane, and the balance is propylene. The carbon four in the refinery enters the pre-separation tower. The number of plates in the pre-separation tower is 130. The operating conditions are: tower top pressure 0.9MPa (absolute), tower top temperature 39.4°C, tower bottom temperature 73.7°C and reflux ratio 26.6. Light ends were withdrawn with an isobutane content (mass) of 51%. After the stream in the tower kettle is preheated to 500°C, it enters the olefin catalytic cracking reactor 10 for reaction. The amount of water vapor is 9850kg / h, and the loading capacity of the catalyst is 7 tons. The catalyst adopts the catalyst of the brand BOC-1 of Beijing Research Institute of Chemical Industry. The conditions are: tempera...

Embodiment 2

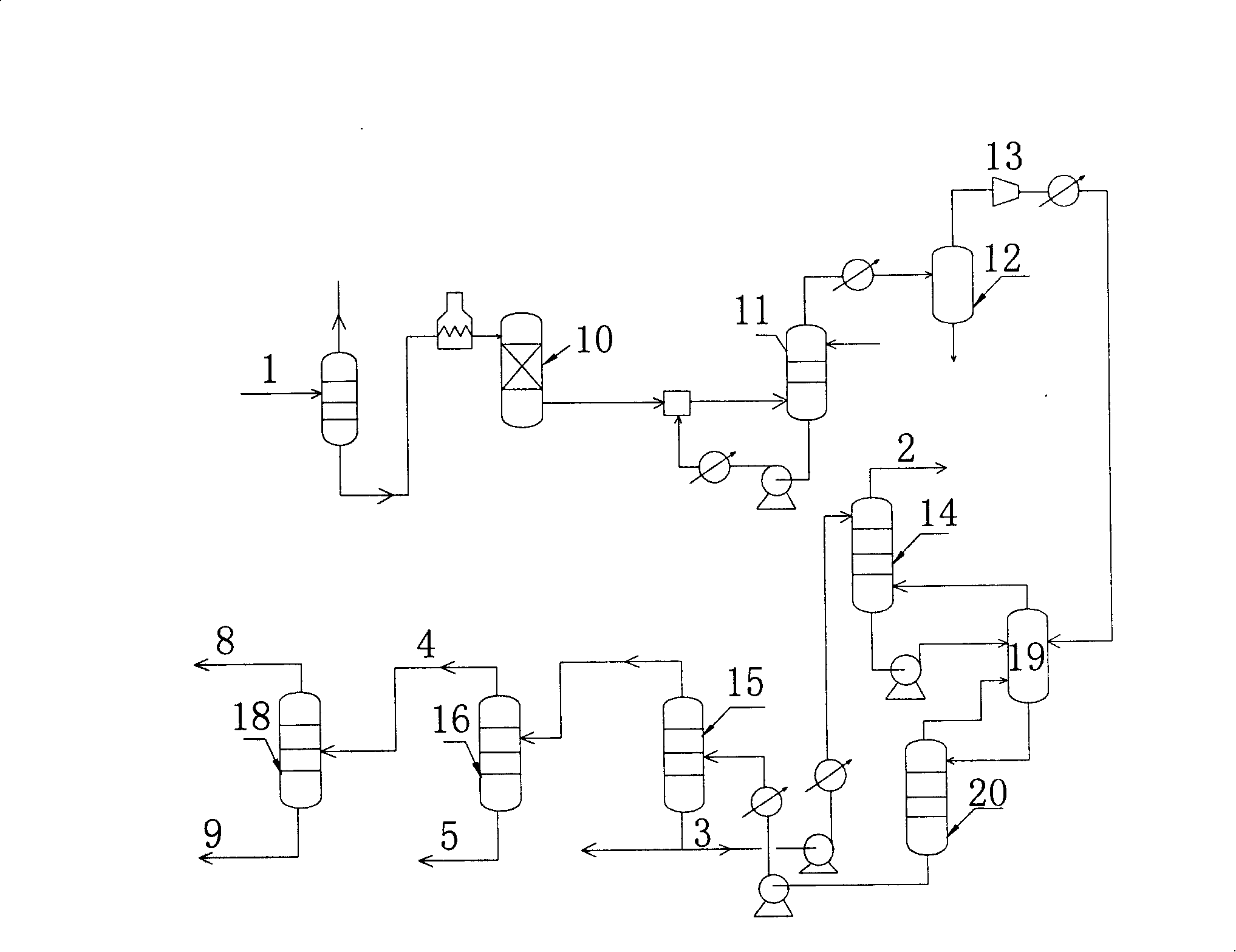

[0045] Reference attached image 3 , using the same raw material as in Example 1, enter the gas-liquid separation tank 19 after the pre-separation tower 1, olefin cracking reactor 10, oil washing tower 11, water washing tower 12, compression unit 13, and the separated gas phase goes to the absorption tower 14 , the separated liquid phase goes to the precipitation tower 20, and the separation tower still stream is sent to the debutanizer 15; the debutanizer overhead stream is sent to the depropanizer 16, and the tower still stream is partially recycled to the absorption tower, and partly extracted, The ratio is 2.8:1; the operating conditions of the above units are the same as in Example 1. The number of plates of the depropanizer is 40, the temperature at the top of the tower is 51° C., the pressure at the top of the tower is 2.0 MPa (absolute), and the reflux ratio is 2. The carbon four components extracted from the bottom of the depropanizer are sent out of the boundary are...

Embodiment 3

[0047] Adopt the raw material identical with embodiment 2, enter gas-liquid separation tank 19 after pre-separation tower 1, olefin cracking reactor 10, oil washing tower 11, water washing tower 12, compression unit 13, through absorption tower 14, separating out tower 20, Debutanizer 15; the debutanizer tower bottom stream is partially recycled to the absorption tower, and part of the extraction is 2.8:1; the debutanizer top stream is sent to the depropanizer 16, and the carbon is extracted from the depropanizer top Three component 6790kg / h, sent out of the boundary area as a product; carbon four component 8780kg / h extracted from the depropanizer tower kettle, sent out of the boundary area as a product. The operating conditions of the above units are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com