Forming method for large high-modulus ellipsoidal molded surface hemispherical shell of aluminum alloy storage box

An aluminum alloy, high-modulus technology, applied in the field of tank forming, can solve the problems of increased cost, many processes, and reduced precision, and achieves the effects of saving energy, shortening the process flow, and improving the forming accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] A specific implementation case is given below. In this implementation case, the raw material of the hemispherical shell of the ellipsoidal surface storage tank is 2219 aluminum alloy, the modulus of the hemispherical shell is 2, the maximum inner diameter in the long axis direction is Ф1339~1340mm, and the wall thickness is The following is the specific process of integral precision forming:

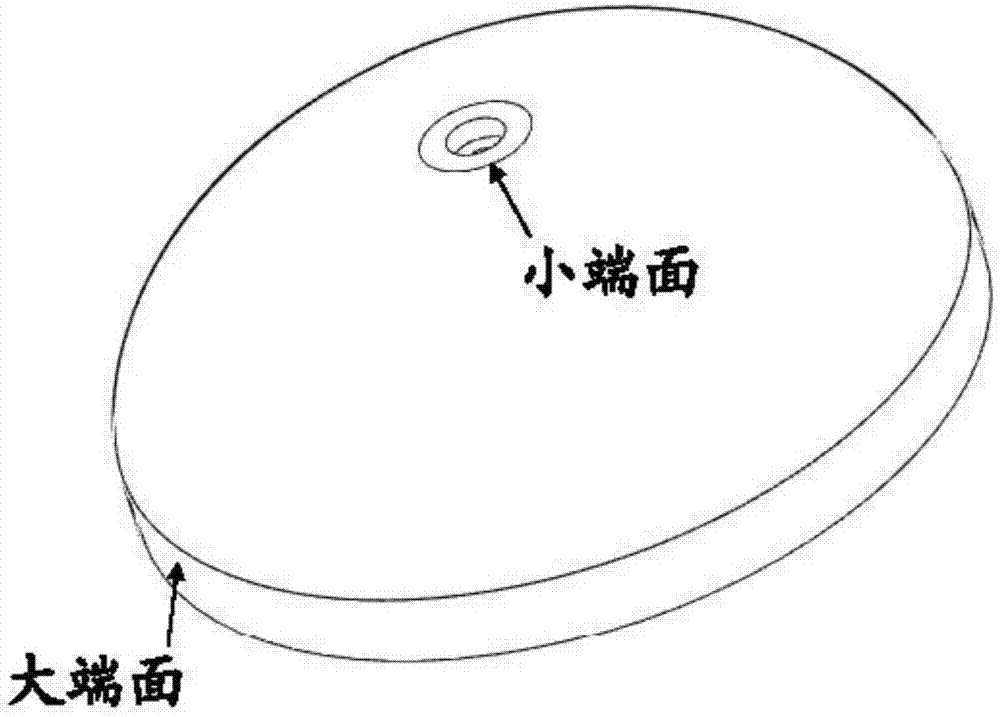

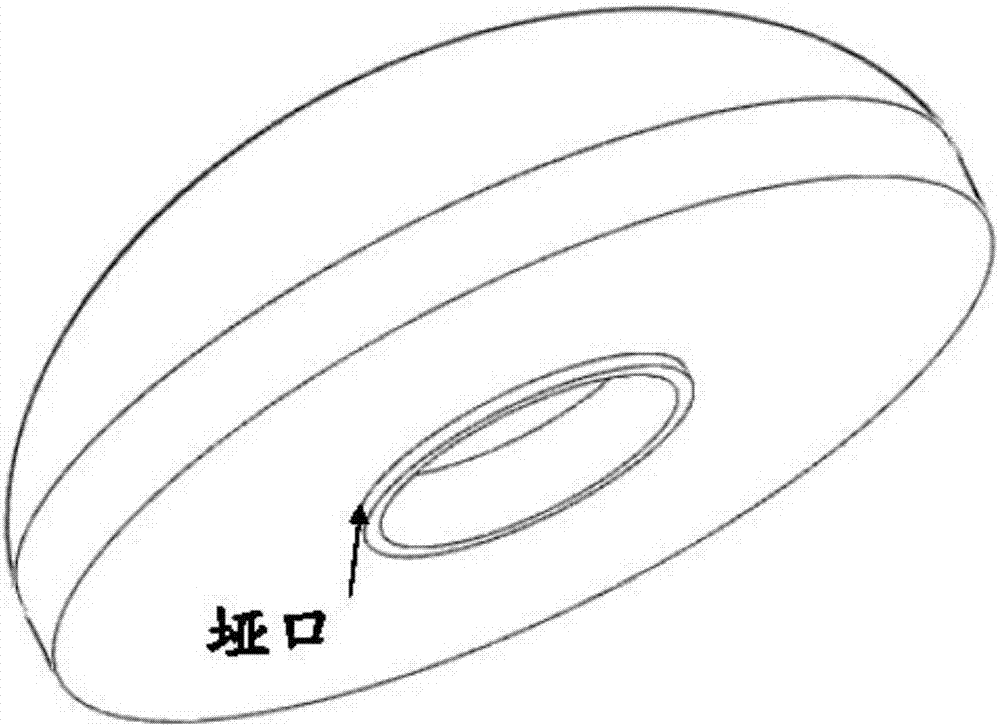

[0091] (1) Manufacture the spinning mold. The spinning mold made is an ellipsoidal hemispherical shell + a straight line segment. The maximum diameters in the long axis direction and short axis direction are Φ1336mm and Φ664mm respectively. In addition, the spinning mold is hollow , A mold with a ribbed structure inside and a small end face with a flat bottom of Φ200-250mm outside, such as Figure 2a and Figure 2b shown.

[0092] (2) Prepare the spinning blank, calculate the specifications of the spinning blank by using the volume constant principle and cut an aluminum alloy d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com