Integrated Solvent Deasphalting and Slurry Hydrocracking Process

a technology of integrated solvent and hydrocracking, which is applied in the direction of hydrotreatment process, hydrocarbon oil cracking, hydrocarbon oil treatment, etc., can solve the problems of high metal contaminants, difficult to upgrade dao products with conventional fcc or hydrocracking, and use either a fixed bed, etc., to achieve high-value distillates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

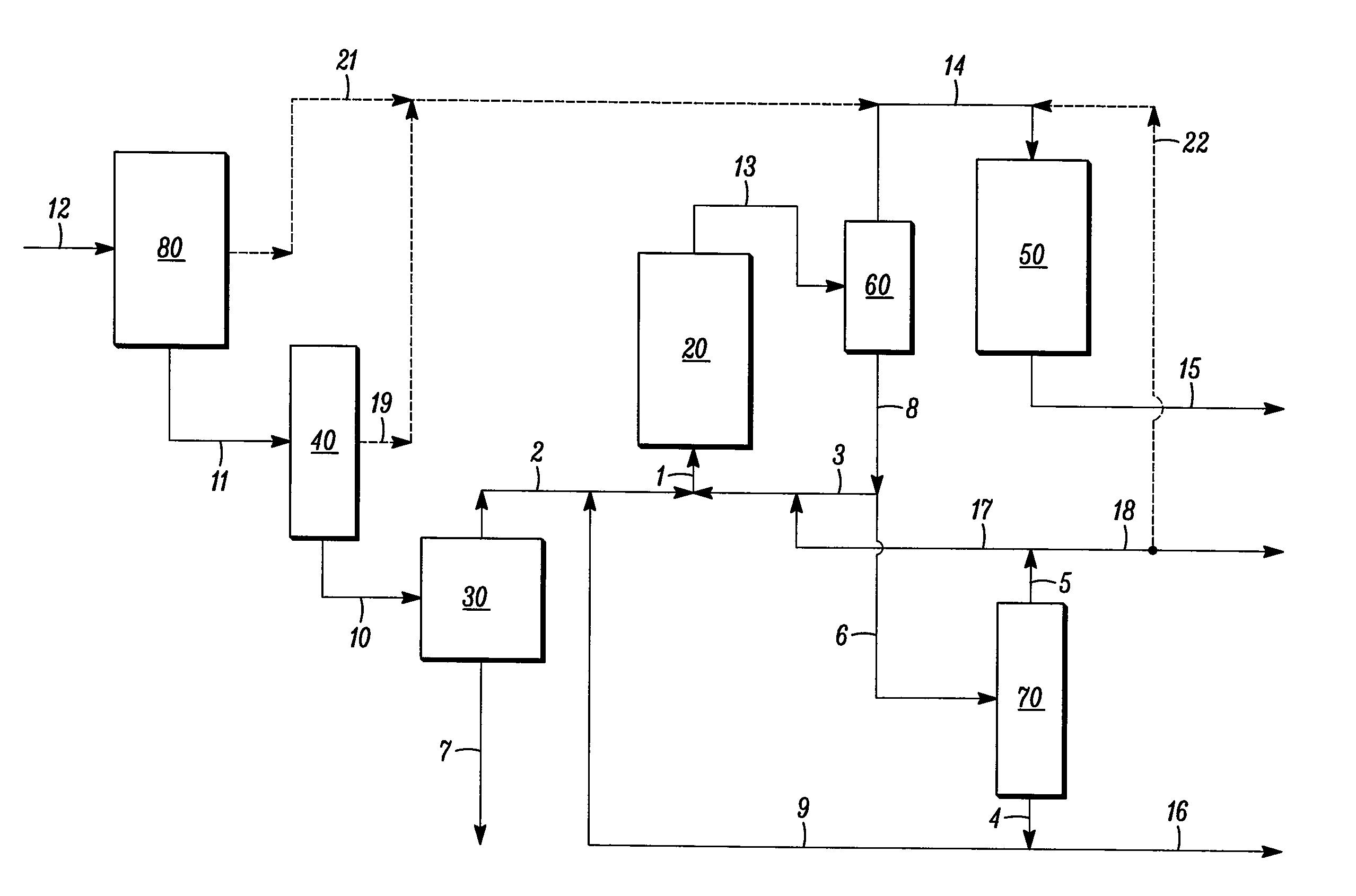

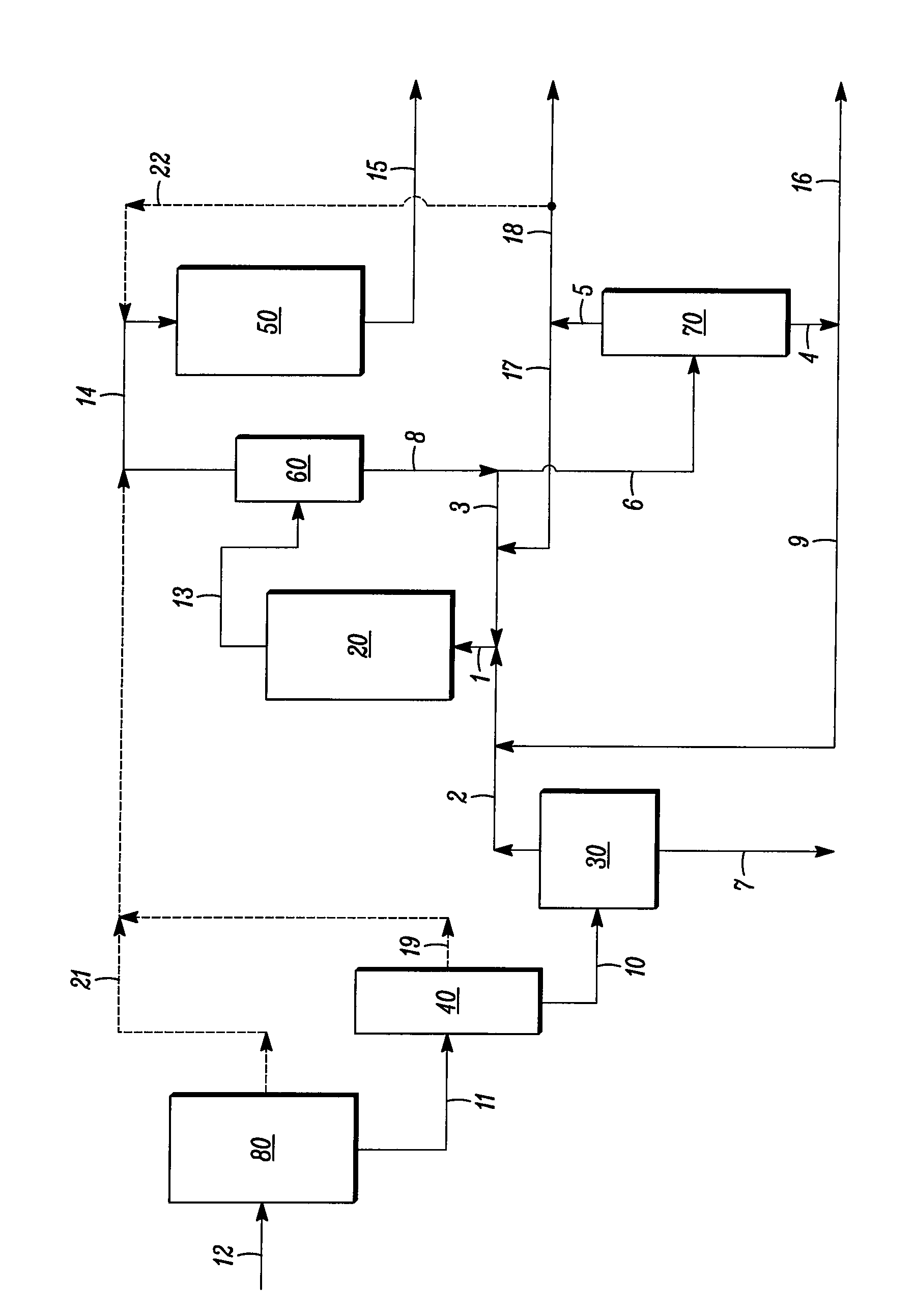

[0018]Embodiments of the invention relate to the use of solvent deasphalting (SDA) in combination with slurry hydrocracking (SHC) to upgrade a heavy hydrocarbon feedstock. A representative heavy hydrocarbon feedstock to the SHC is a mixture of deasphalted oil (DAO), as a fresh feed component, and at least one liquid product recovered from the SHC effluent and recycled to an SHC reactor (or reaction zone). The DAO is often obtained from subjecting a crude oil vacuum distillation column residue to solvent deasphalting in the presence of a solvent. The heavy hydrocarbon feedstock to SHC may therefore comprise all or a portion of DAO produced from SDA, either directly from this process or following one or more pretreatment and / or fractionation steps. To reduce the overall costs and complexity of the integrated process, the DAO is usually not subjected to an additional extraction (e.g., involving phase separation), prior to passing the DAO to SHC for use as a heavy hydrocarbon feedstock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com