Method of extracting and separating crude oil

A technology for extraction and crude oil, which is applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of inconspicuous separation effect and incomplete removal of metal components, so as to reduce operating costs and equipment costs, and reduce processing costs. The effect of pressure, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

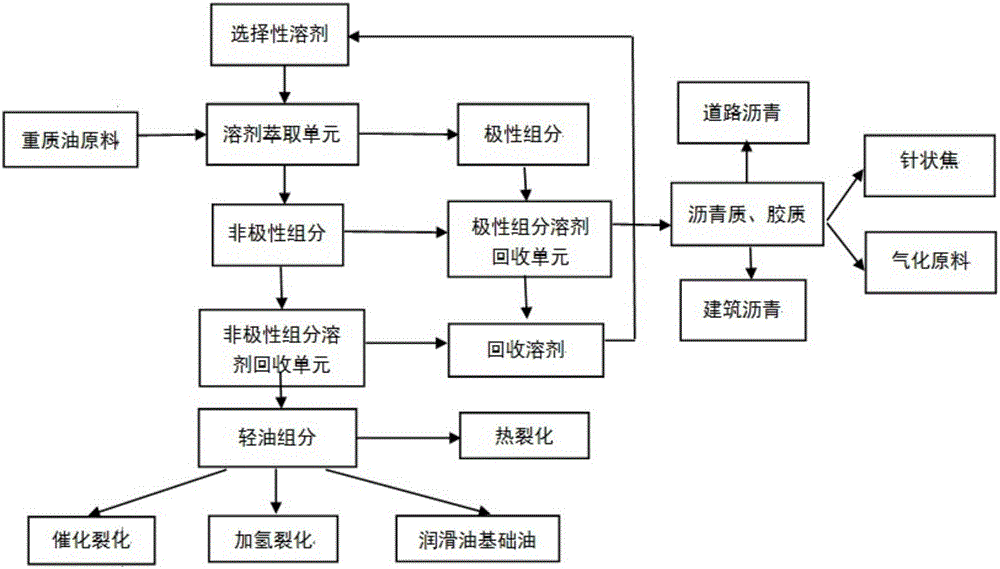

[0033] This embodiment provides a method for extracting and separating crude oil, the process of which is as follows figure 1 shown. The method includes the following steps:

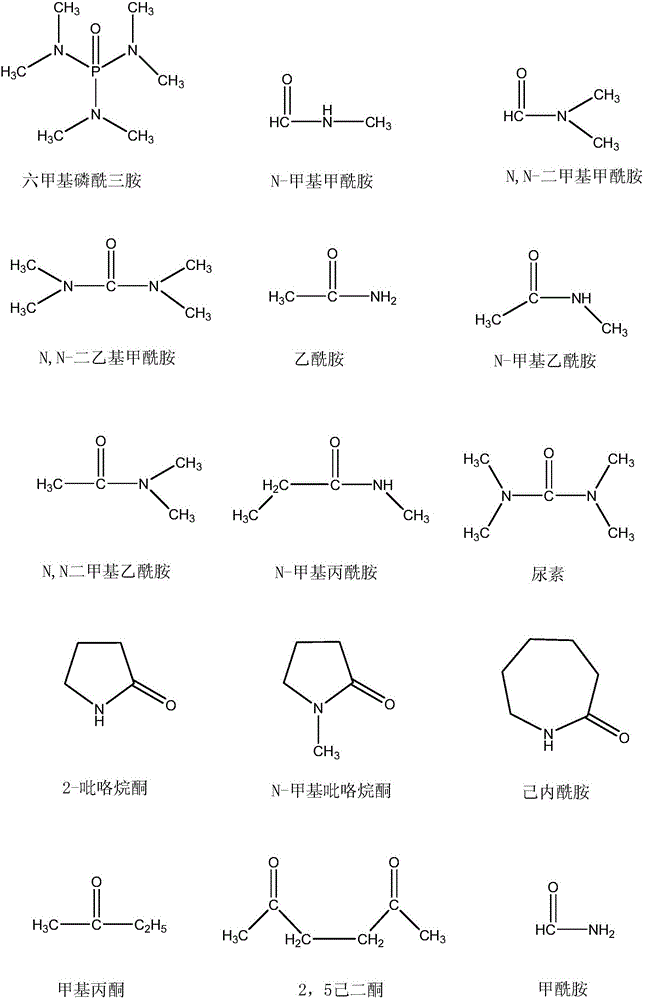

[0034] Add hexamethylphosphoric triamide to the extraction equipment first, then add crude oil 1, the mass ratio of agent to oil is 3:1, the heating temperature of the water bath is 80°C, the pressure is 0.1MPa, stir for 5 minutes, and let it settle for 10 minutes , the solution appears to be clearly stratified, and the stratified solution is separated. The raffinate is mainly aliphatic hydrocarbons, light aromatics and a small amount of solvent, and the extract is mainly condensed ring aromatics, colloids, asphaltenes and a large amount of solvent.

[0035] The extract and raffinate are polar components and non-polar components respectively. The crude oil 1, extract and raffinate are subjected to four-component analysis and S, N and metal Ni, V, Ca, Mg content detection, The results obtained are shown...

Embodiment 2

[0044] This embodiment provides a method for extracting and separating crude oil, the process of which is as follows figure 1 shown. The method includes the following steps:

[0045] First add 1,3 dimethyl 2-imidazolidinone into the extraction equipment, and then add crude oil 1, the mass ratio of agent to oil is 3:1, the heating temperature of the water bath is 80°C, the pressure is 0.1MPa, and the stirring is continued for 5 minutes. After standing and settling for 10 minutes, the solution appeared to be clearly stratified, and the stratified solution was separated. The raffinate was mainly aliphatic hydrocarbons, light aromatics and a small amount of solvent, and the extract was mainly polycyclic aromatic hydrocarbons, colloids, asphaltene and a large amount of solvents .

[0046] The extract and the raffinate correspond to polar components and non-polar components in the present invention respectively, carry out four-component analysis and S, N and metal Ni, V, Ca, Mg c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com