Method of utilizing copper smelting slag to remove SO2, NOx and Hg in nonferrous smelting flue gas

A technology for smelting flue gas and copper smelting slag, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of many types of additives, complex absorbent components, complex waste liquid components, etc. The effect of economic benefit, simple preparation method and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

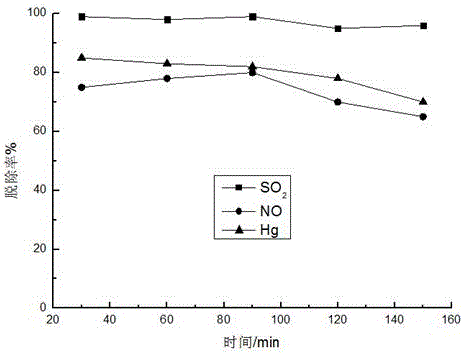

Embodiment 1

[0023] Dry the medium ore from Yunxi Copper Industry at 80°C, then grind and sieve it into 200-400 mesh; mix the obtained copper slag powder with tap water in a certain proportion, and the solid content of the mixed copper slag slurry is the mass The percentage is 15%; the gas is passed through the gas absorption bottle containing copper slag slurry; the amount of copper slag slurry is 25mL; 2 The concentration is 1000mg / L, the NO concentration is 300mg / L, and the Hg concentration is 30mg / L. The simultaneous removal effect of three kinds of pollutants is shown in figure 1 As shown, it can be seen from the figure that when the middle ore of Yunnan Copper Industry is selected to make copper slag slurry with a solid content of 15%, it is measured that within 90 minutes of absorption, SO in the flue gas 2 Concentration 2 The average removal rate is >98%, the average NO removal rate is >70%, and the average Hg removal rate is >80%.

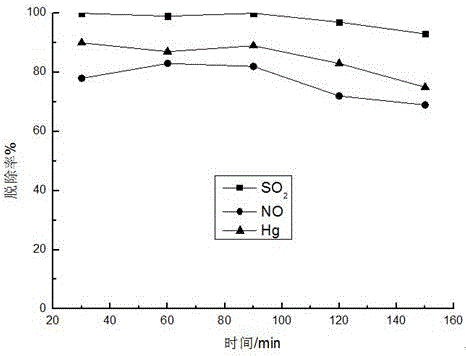

Embodiment 2

[0025] Dry the medium ore from Yunxi Copper Industry at 90°C, then grind and sieve it into 300-400 mesh; mix the obtained copper slag powder with tap water in a certain proportion, and the solid content of the mixed copper slag slurry is the mass The percentage is 45%; the gas is passed through the gas absorption bottle containing copper slag slurry; the amount of copper slag slurry is 25mL; 2 The concentration is 1300mg / L, the NO concentration is 400mg / L, and the Hg concentration is 40mg / L. The simultaneous removal effect of three kinds of pollutants is shown in figure 2 As shown, it can be seen from the figure that when the middle ore of Yunnan Copper Industry is selected to make copper slag slurry with a solid content of 45%, it is measured that within 90 minutes of absorption, SO in the flue gas 2 Concentration 2 The average removal rate is >99%, the average NO removal rate is >75%, and the average Hg removal rate is >90%.

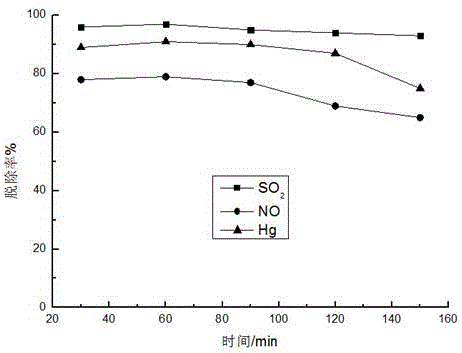

Embodiment 3

[0027] Dry the medium ore from Yunxi Copper Industry at 100°C, then grind and sieve it into 200-300 meshes; mix the obtained copper slag powder with tap water in a certain proportion, and the solid content of the mixed copper slag slurry is the mass The percentage is 60%; the gas is passed through the gas absorption bottle containing copper slag slurry; the amount of copper slag slurry is 25mL; 2 The concentration is 1500mg / L, the NO concentration is 500mg / L, and the Hg concentration is 50mg / L. The simultaneous removal effect of three kinds of pollutants is shown in image 3 As shown, it can be seen from the figure that when the middle ore of Yunnan Copper Industry is selected to make copper slag slurry with a solid content of 60%, it is measured that within 90 minutes of absorption, SO in the flue gas 2 Concentration 2 The average removal rate is >95%, the average NO removal rate is >75%, and the average Hg removal rate is >90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com