Method for on-site detecting and metering fume discharge total amount and fume concentration on-site detecting and metering instrument

A technology for on-site detection and oil fume concentration, which is applied in the direction of measuring device, specific gravity measurement, relative volume flow measurement, etc., can solve the problems of impossible fast detection on the spot of cooking, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

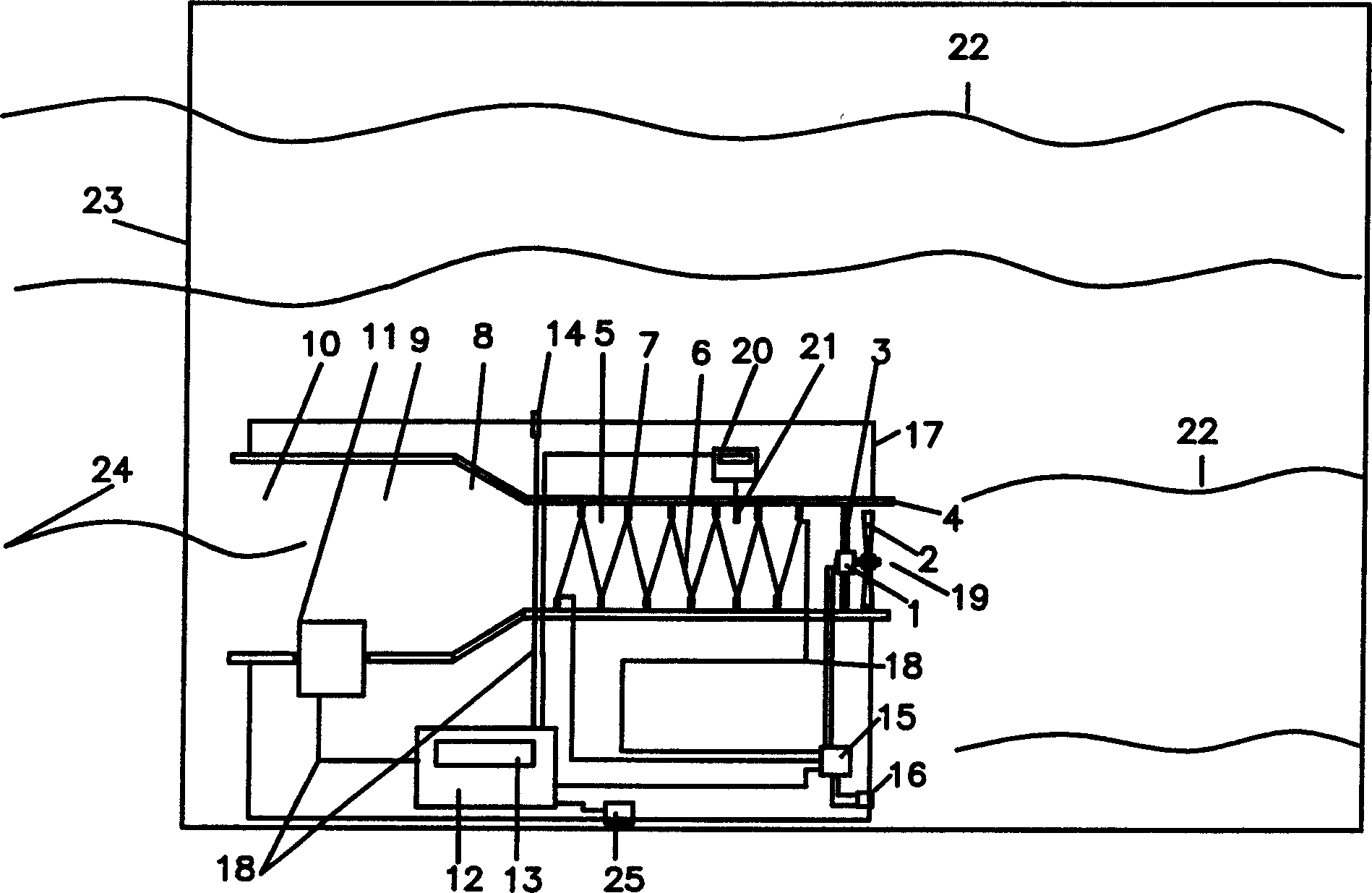

Image

Examples

Embodiment Construction

[0045] The method for on-the-spot detection and metering total amount of oil fume discharge of the present invention is described as follows:

[0046] a. Use a certain negative pressure generated by the exhaust fan to extract the oily fume air to be tested.

[0047] b. Use a carbon dioxide detector to detect the concentration of carbon dioxide in the extracted airflow.

[0048] c. Turn on the heat source set in the specific reaction chamber to keep the temperature of the reaction chamber not lower than 150°C and not higher than 850°C.

[0049] d. Use the same negative pressure generated by the exhaust fan to extract the oily fume air to be tested.

[0050] e. Let the extracted air flow containing oil fumes enter the reaction chamber through the inlet of the reaction chamber at a certain speed.

[0051] f. Let the residence time of the air flow in the reaction chamber be no less than 0.05 seconds, so that the contained oil fume is fully oxidized.

[0052] g. Detect the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com