Method for preparing anode catalyst of direct methanol fuel cell

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high mass production cost of catalysts, easily poisoned methanol, and low working temperature, and achieve good methanol oxidation Catalytic activity, improved resistance to CO poisoning, and improved surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

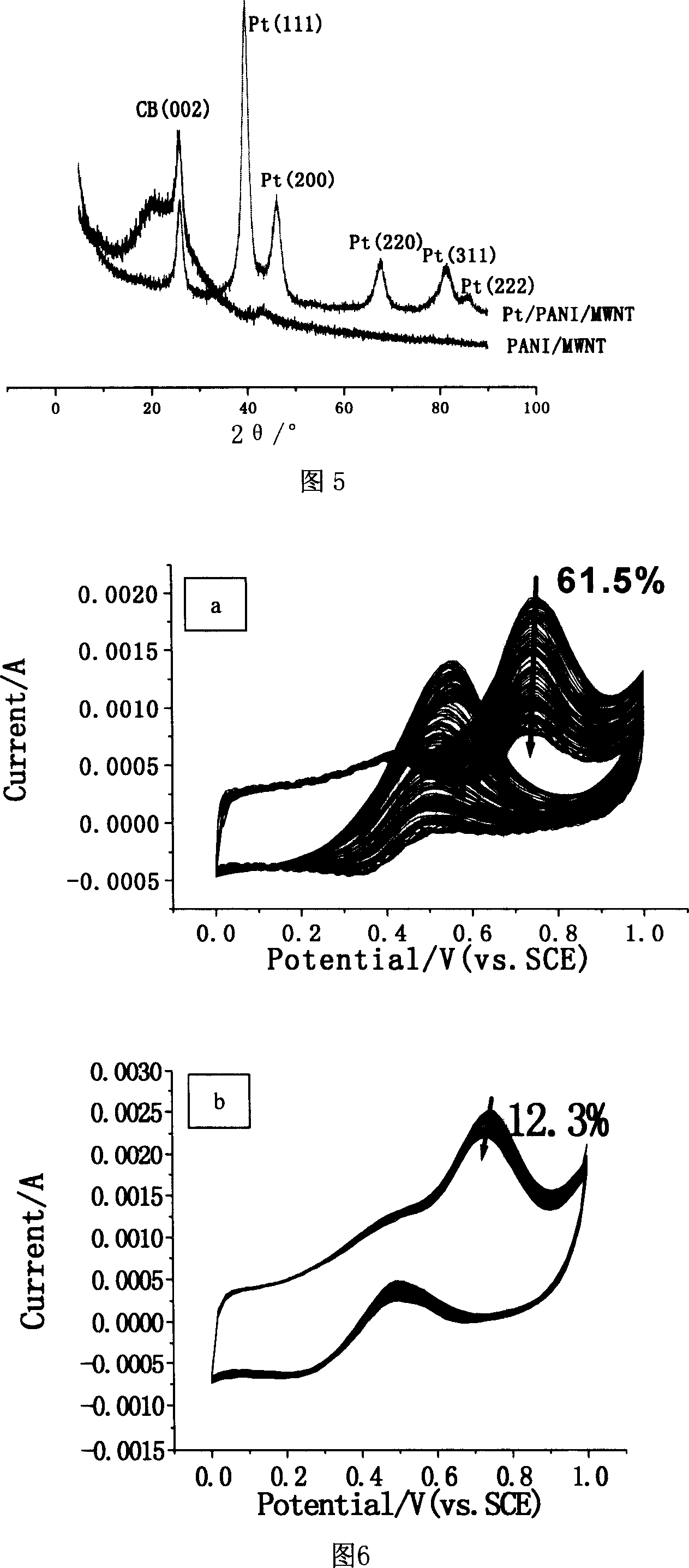

[0039] (1) Preparation of composite carrier: take a single-necked flask as a reaction vessel, first add 100ml of 1mol / L sulfuric acid solution containing 0.1g of polyvinyl alcohol, add 0.1gMWNT, ultrasonically shake at room temperature for 4h, then add 0.067gANI, and then slowly drop Add 2.4 times the amount of aniline ammonium persulfate (APS) solution. Reaction at 0°C for 8h. Wash, tumble dry, and set aside. The SEM images of the polyaniline / multi-walled carbon nanotube composite carrier and the multi-walled carbon nanotube carrier are shown in Figure 1, where a is the SEM image of the polyaniline / multi-walled carbon nanotube composite carrier, and b is the multi-walled carbon nanotube carrier SEM image. The FTIR diagram of the polyaniline / multi-walled carbon nanotube composite carrier and the multi-walled carbon nanotube carrier is shown in Figure 2, where curve a is the FTIR diagram of the polyaniline / multi-walled carbon nanotube composite carrier, and curve b is the mul...

Embodiment 2~5

[0044] Examples 2-5: The input amount of ANI and MWNT, the amount of polyvinyl alcohol used in the preparation process of the PANI / MWNT composite carrier and the amount of chloroplatinic acid used in the platinum deposition process were changed, and other conditions were kept unchanged, see Table 1.

[0045] Table 1

[0046] Example

Embodiment 6

[0048] (1) Preparation of the composite carrier: take a single-necked flask as the reaction vessel, first add 100ml of 1mol / L sulfuric acid solution containing 0.1g of polyethylene glycol octylphenyl ether, add 0.1g of MWNT, ultrasonically shake for 4 hours at room temperature, and then add 0.067gANI, then slowly add dropwise an ammonium persulfate (APS) solution of 2.4 times the amount of aniline. Reaction at 0°C for 8h. Wash, tumble dry, and set aside.

[0049] (2) Take 0.1 g of PANI / MWNT composite carrier powder into a reaction flask, add 100 ml of acetic acid buffer solution (pH=3.5) containing 10% isopropanol, and oscillate ultrasonically for 2 hours until a uniform dispersion system is formed.

[0050] (3) Measure 3.3ml of 0.0386mol / L chloroplatinic acid (H 2 PtCl 6 ) solution in the dispersion, continue to shake for 60min.

[0051] (4) Heat up to 60°C, add excess sodium borohydride solution dropwise, react for 1.5 hours, filter, wash until chloride-free, and dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com