A process and equipment for synergistically removing dust and dioxin

A dust and removal technology, applied in the field of flue gas purification, can solve the problems of easy condensation on the surface of the bag filter, high moisture content in the flue gas, and high equipment cost, reducing one-time investment, improving reactivity, and small investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

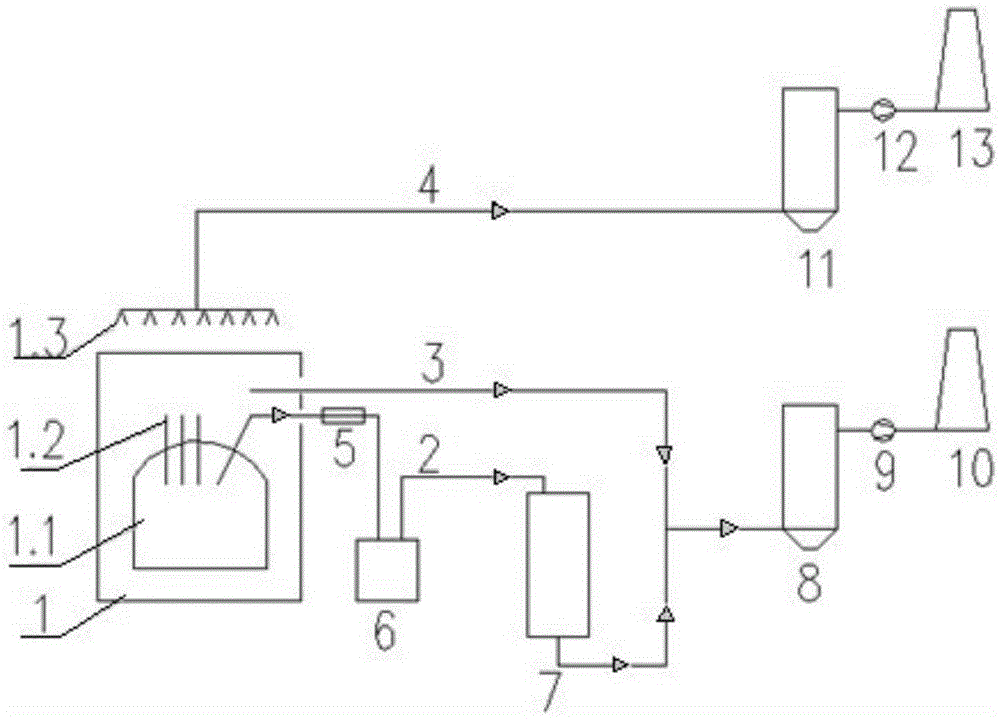

[0040] figure 1 It is a schematic structural diagram of a device for synergistically removing dust and dioxins of the present invention. As shown in the figure, a 50t electric furnace includes an electric furnace doghouse airtight cover 1 and an electric furnace body 1.1, and the electric furnace body 1.1 has four electrodes 1.2 , through electrode 1.2 discharge to smelt scrap steel, four-hole smoke exhaust smoke is discharged from the electrode hole of the fourth electrode, at this time the temperature is about 1200-1400°C, and the original particle content is 10g / Nm 3 , the average particle size is 13~35μm, and the concentration of dioxin is 2~10ng-TEQ / m 3 , The flue gas velocity is about 1.5m / s.

[0041] During the smelting process, kennel flue gas will be produced at the same time, the initial temperature is about 80°C, and the dioxin concentration in it is 2-10ng-TEQ / m 3 ; During the non-smelting period, roof hood flue gas 4 will be generated in the airtight hood 1 of t...

Embodiment 2

[0046] refer to figure 1 , the flue gas from the four-hole smoke exhaust and the flue gas from the kennel respectively pass through the channel I2 and the channel II3 to cool down under the action of the induced draft fan I9, and then they are introduced into the dust collector I8; Settling chamber 6, waste heat boiler / mechanical air cooler 7; at the dust collector Ⅰ8, the particle dust in the four-hole smoke exhaust gas and the doghouse flue gas is filtered on the surface of the filter bag of the dust collector Ⅰ8 to realize the dust in the flue gas purification; the purified flue gas passes through the catalyst powder contained in the fiber material inside the filter bag to realize the catalytic decomposition of dioxins in the four-hole flue gas and doghouse flue gas, and finally is discharged through the chimney I2; the flue gas of the roof cover Under the action of the induced draft fan II12, it enters the dust collector II11 through the channel III4, and after the dust pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com