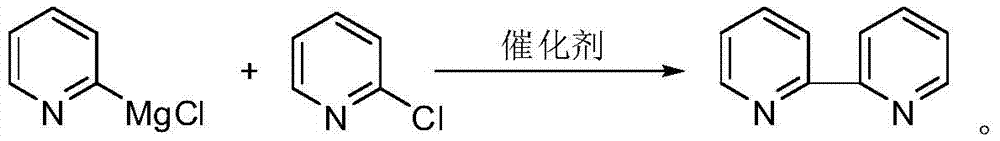

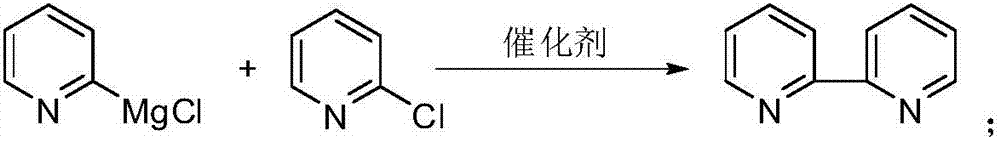

A kind of preparation method of 2,2'-bipyridine

A technology of bipyridine and chloropyridine, which is applied in the field of preparation of 2,2'-bipyridine, can solve the problems of high production cost and high price of 2,2'-bipyridine, and achieve low price and low production cost , the effect of not being poisoned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Get 30ml of anhydrous tetrahydrofuran (THF) solution of 2-chloropyridine Grignard reagent (which contains 10mmol of 2-chloropyridine Grignard reagent), add 0.3mmol of MnCl 2 And 9.5mmol of 2-chloropyridine, reacted at room temperature for 1h. The reaction mixture was quenched with water, then extracted with dichloromethane, filtered, and dichloromethane washed the filter cake, and the liquid part obtained by washing was left to stand for phase separation, and the organic phase was collected. The organic phase was distilled off the solvent under reduced pressure to obtain a crude product, which was then distilled under reduced pressure to obtain 1.17 g of a white solid.

[0029] It was determined that the melting point of the white solid was 69.4-69.8°C, MS: m / z=156.1, and it was determined to be 2,2'-bipyridine.

Embodiment 2

[0031] Add 0.6g (0.025mol) of magnesium chips into a 100mL three-necked flask, and replace with nitrogen three times. Take 4.54g (0.04mol) 2-chloropyridine and 45.4g THF to form the first solution. A small amount of the first solution was added to the three-necked flask replaced by nitrogen, and then 0.2 g (10 mol%) of bromoethane was added at room temperature to initiate the Grignard reaction, and the remaining first solution was continued to be added dropwise after initiation. After the dropwise addition, add 0.16g (3mol%) of anhydrous MnCl 2 , Continue to stir the reaction for 1h and then stop the reaction. Then add 5g of water to the there-necked flask to quench, add 10ml of dichloromethane for extraction, filter, dichloromethane rinses the filter cake, the liquid part is left to stand for phase separation, collects the organic phase, and evaporates the solvent under reduced pressure to obtain the crude product. Pressure distillation afforded 2.18 g of white solid.

[0...

Embodiment 3

[0034] Add 0.024mol magnesium chips into a 100mL three-necked flask, and replace with nitrogen three times. Take 4.54g (0.04mol) 2-chloropyridine and 45.4g THF to form the first solution. A small amount of the first solution was added to the three-necked flask replaced by nitrogen, and then 0.2 g (10 mol%) of bromoethane was added at room temperature to initiate the Grignard reaction, and the remaining first solution was continued to be added dropwise after initiation. After the dropwise addition is completed, add 0.16g (3mol%) of anhydrous CoCl 2 , After continuing to stir the reaction for 1h, stop the reaction. Then add 5g of water to the there-necked flask to quench, add 10ml of dichloromethane for extraction, filter, dichloromethane rinses the filter cake, the liquid part is left to stand for phase separation, collects the organic phase, and evaporates the solvent under reduced pressure to obtain the crude product. Pressure distillation afforded 2.1 g of white solid.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com