Process for delayed coking of undoped full-fraction ethylene tar

A technology of ethylene tar and delayed coking, which is applied in the petroleum industry, cracking, processing of hydrocarbon oil, etc., can solve the problem of low liquid yield and light fuel oil product yield, and no full fraction ethylene tar has been found to have delayed coking, unable to produce Coke oven tube and other problems, to achieve the effect of reducing pre-treatment process, avoiding coking phenomenon, and large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

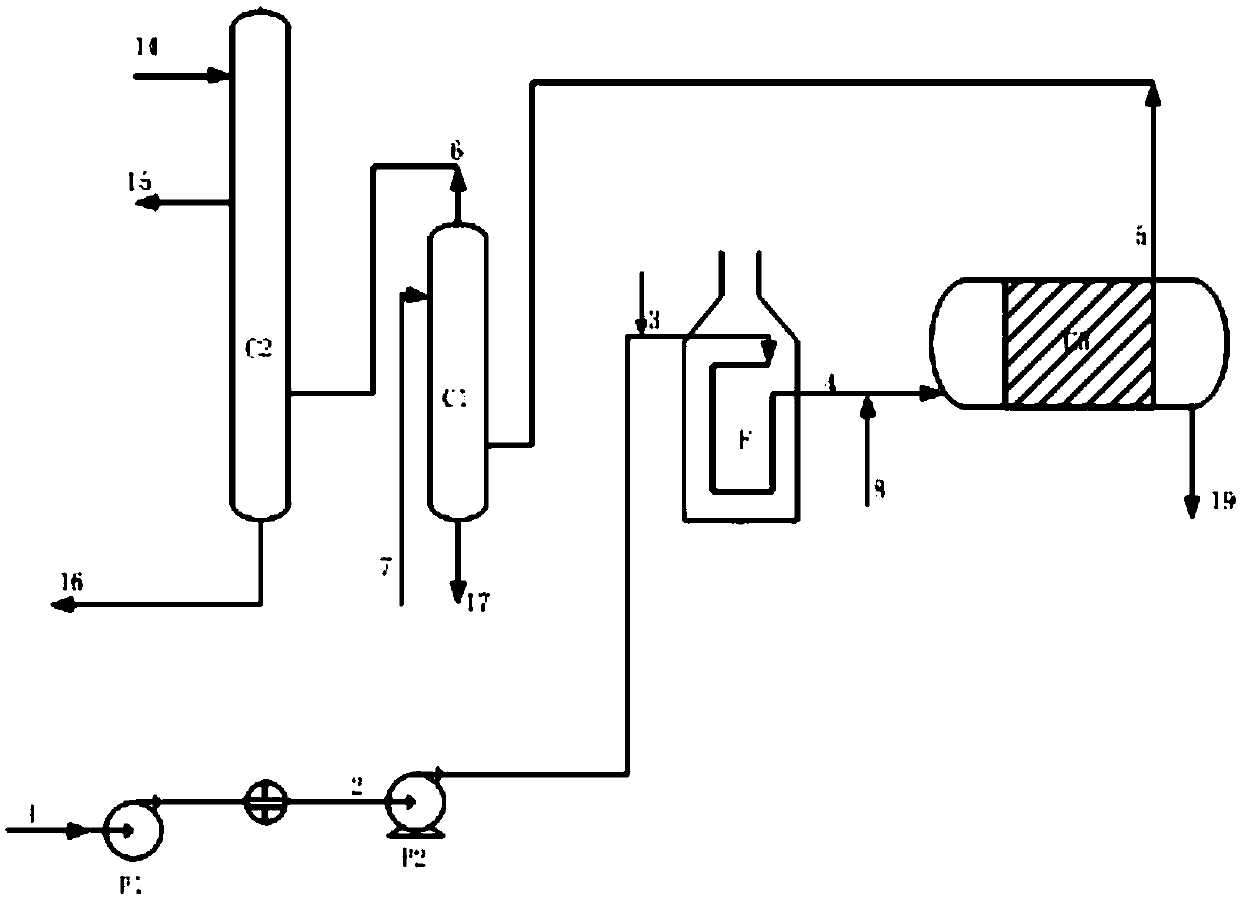

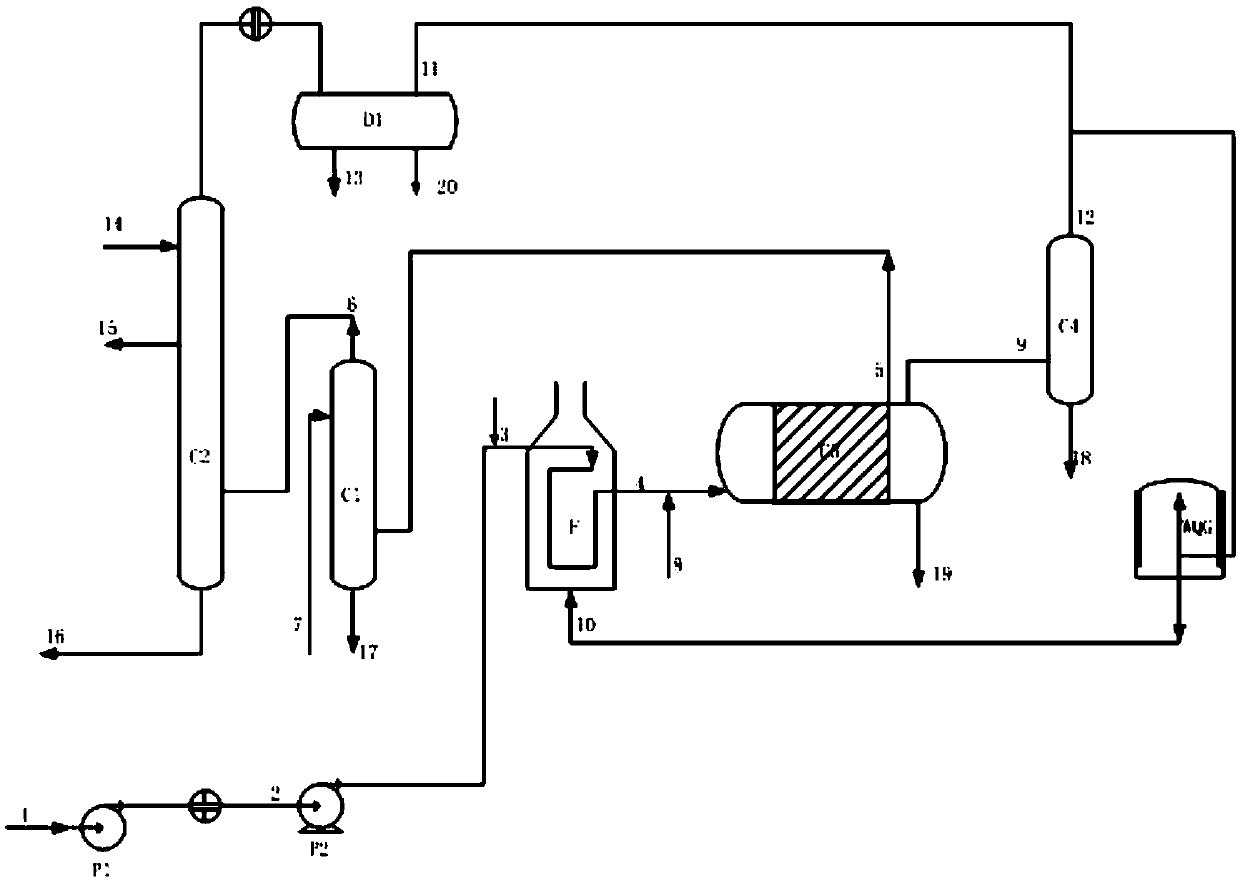

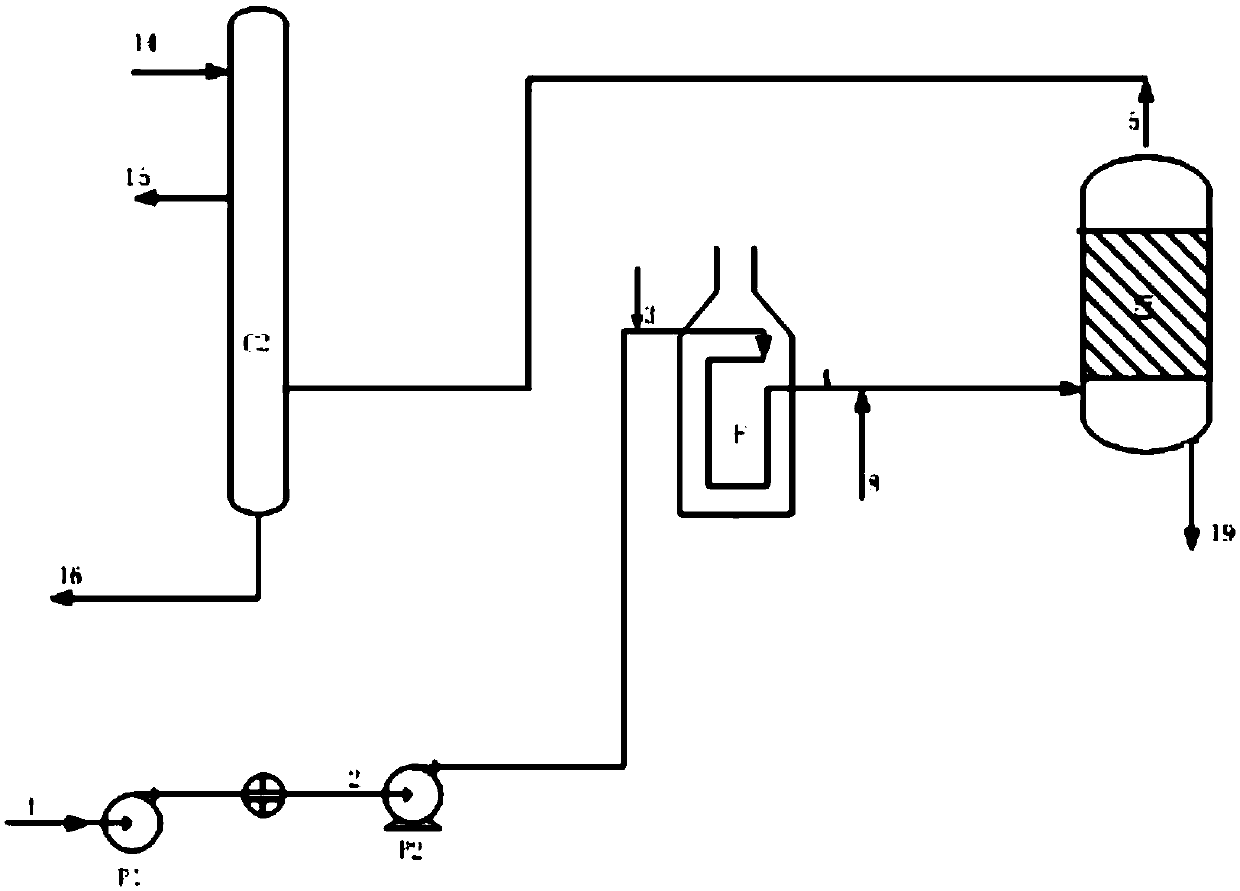

[0069] like figure 2 The shown delayed coking equipment doped with full-fraction ethylene tar implements the delayed coking process of ethylene tar. The details are as follows. After the ethylene tar is preheated at 160 degrees, it enters the heating furnace, injects water with 2% of the raw material ethylene tar, and passes through the heating furnace. The temperature of the convection section and the radiation section is rapidly raised to 460°C; the heated ethylene tar enters the coking kettle, the circulation ratio of the coking kettle is 5%, and a series of reactions such as cracking and condensation occur in the coking kettle to generate rich gas, solvent oil, high Softening point asphalt and coke, high softening point asphalt and coke agglomerated in the kettle. The temperature of the oil and gas in the kettle is 440°C, which is cooled to 410°C by quenching oil, and then flows out from the top of the coking kettle and enters the oil and gas into the atmospheric fraction...

Embodiment 2

[0079]As shown in Figure 2, the ethylene tar is extracted from the raw material oil-gas separator, and the normal pressure heat exchanger is preheated to 150°C, and the preheated ethylene tar is sent to the heating furnace with a relay pump, and the raw material ethylene tar is injected with 2% of the raw material ethylene tar. Water injection, heat exchange through the flue pipe of the heating furnace, and then enter the convection section and radiation section, and quickly heat up to 450°C; the heated ethylene tar enters the coking kettle through the four-way valve, and cracks and condenses in the coking kettle. The circulation ratio of the coking kettle is 8%, and rich gas, high softening point pitch and coke are generated, and the high softening point pitch and coke are agglomerated in the kettle. The temperature of the oil and gas in the kettle is 450°C, which is cooled to 410°C by the quenching oil, and then flows out from the top of the coking kettle and enters the washi...

Embodiment 3

[0090] like figure 2 As shown, the ethylene tar is extracted from the raw material oil-gas separator, and the normal pressure heat exchanger is preheated to 170°C, and the preheated ethylene tar is sent to the heating furnace with a relay pump, and the water injection is 2% of the raw material ethylene tar. Heat exchange through the flue pipe of the heating furnace, and then enter the convection section and radiation section, and quickly heat up to 470°C; the heated ethylene tar enters the coking kettle through the four-way valve, and the circulation ratio of the coking kettle is 7%. Cracking and condensation reactions occur in the kettle to generate rich gas, high softening point asphalt and coke, and the high softening point asphalt and coke are agglomerated in the kettle. The temperature of the oil and gas in the kettle is 445°C, which is cooled to 410°C by quenching oil, and then flows out from the top of the coking kettle and enters the washing tower; after washing, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com