Treatment method of nonbiodegradable organic wastewater

A technology that is refractory to biodegradation and treatment methods, applied in the field of wastewater treatment, can solve the problems of easy poisoning and deactivation of catalysts, high operating costs of equipment, etc., and achieve the effect of reduced process difficulty and operating costs, and less poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

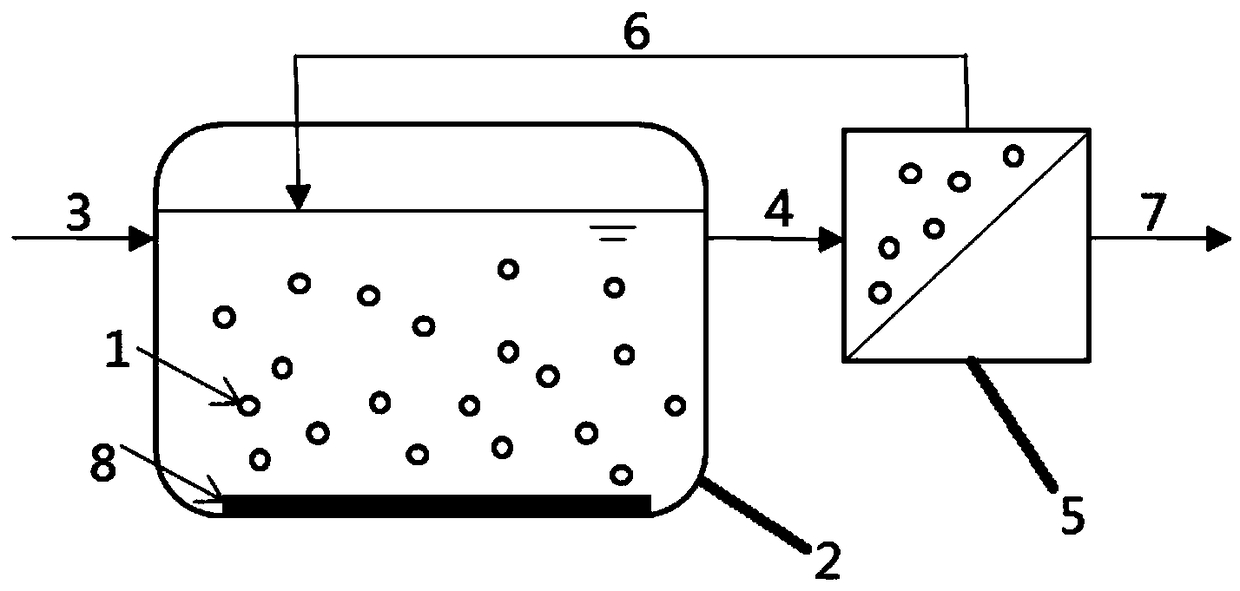

Image

Examples

Embodiment 1

[0025] The organic wastewater to be treated is 100mg / L sodium humate solution, and the reactor adopts a fully mixed batch operation, and the NiCo in the reactor 2 o 4 The catalyst concentration is 5g / L, the pH is 10, the reaction temperature is 90°C, pure oxygen is introduced, and the oxygen flow rate is 0.25L / min. After 3 hours of reaction, the final effluent of separator 5 is detected, and the total organic carbon (TOC) The removal rate is 89%. However, in the common wet catalytic oxidation treatment process, TOC is hardly removed under normal pressure and temperature conditions.

Embodiment 2

[0027] The organic wastewater to be treated is 500mg / L alkali lignin solution, and the reactor adopts full-mixing intermittent operation, and the NiCo in the reactor 2 o 4 The catalyst concentration was 5g / L, the pH was 10, the reaction temperature was 90°C, pure oxygen was introduced, and the oxygen flow rate was 0.25L / min. After 3 hours of reaction, the removal rate of total TOC was 84%.

Embodiment 3

[0029] The organic wastewater to be treated is anaerobic digestion liquid, and the reactor adopts full-mixing intermittent operation, and the NiCo in the reactor 2 o 4 The catalyst concentration was 1g / L, the pH was 8, the reaction temperature was 60°C, air was introduced, and the oxygen flow rate was 0.02L / min. After 12 hours of reaction, the removal rate of total TOC was 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com