Catalyst system for preparing fuel oil from shale oil through catalytic hydrogenation and use method of catalyst system

A catalytic hydrogenation and catalyst technology, which is applied in the chemical industry, can solve the problems of easily destroying the acid center of the hydrogenation catalyst, high production costs, and decreased device stability, and achieves extended effective reaction time, low safety performance requirements, and production. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present application will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present application, but not to limit the present application.

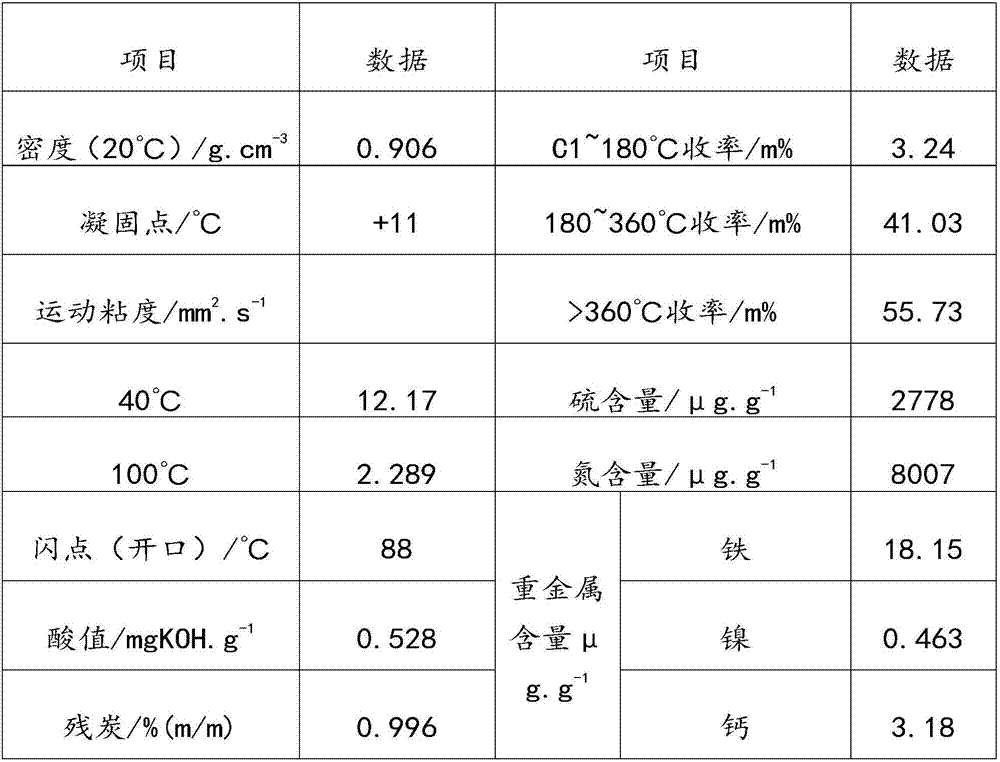

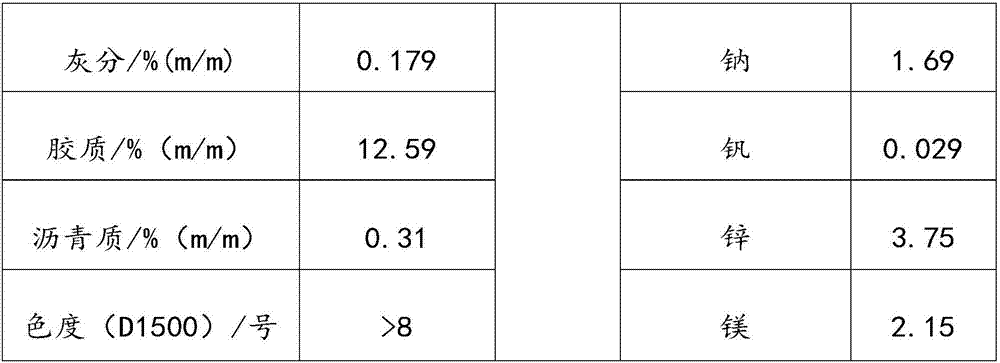

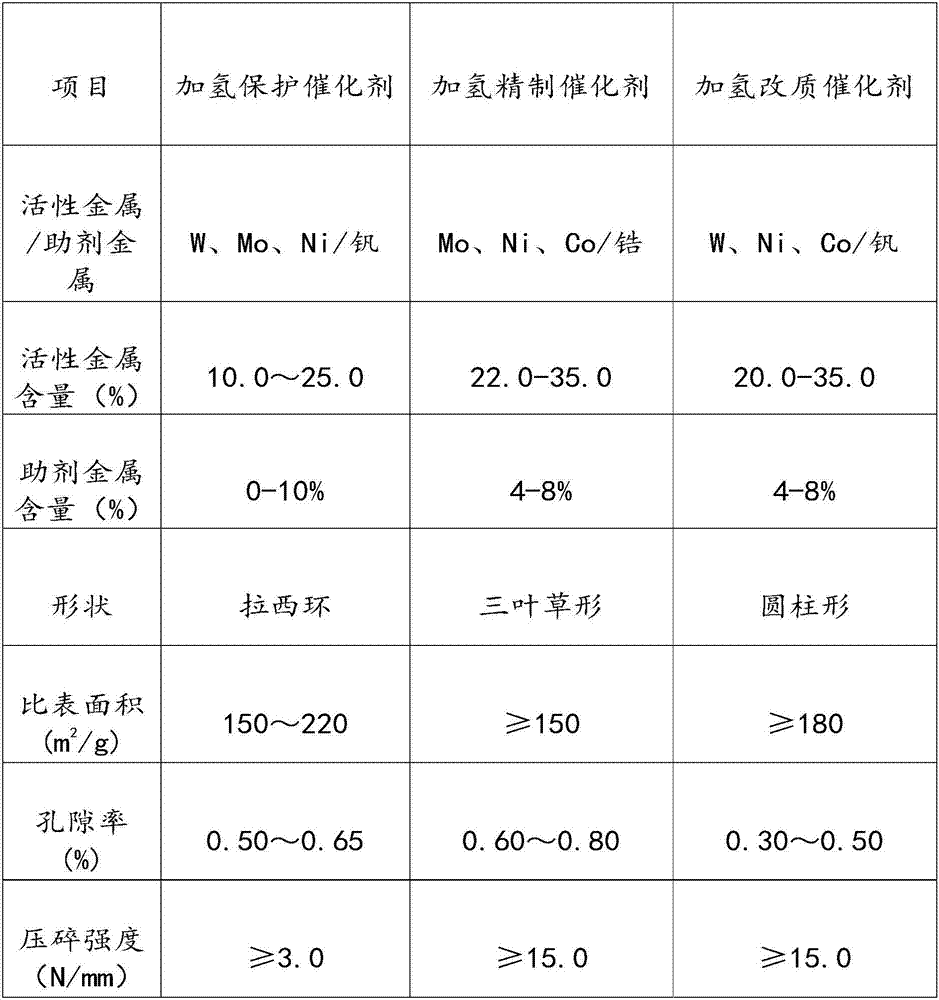

[0029] The invention provides a catalyst system for preparing fuel oil by catalytic hydrogenation of shale oil. Through the selection of carrier, active metal and additive metal, as well as the control of catalyst loading settings, porosity, bulk density, etc., the reaction system is easy to operate. The reacted metastable substances are reacted (these substances are coked at high temperature), reducing the intensity of the reaction and ensuring the smooth and orderly reaction; it solves the problem that the shale oil full fraction colloid and asphaltene high hydrogenation unit cannot operate for a long time At the same time, it also solves the problem of high nitrogen content and low sulfur content in the whole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com