Method for preparing water-soluble polymer by auto-deposition polymerization initiated by ultraviolet light

A water-soluble polymer and self-deposition technology, applied in the field of precipitation polymerization, can solve the problems of high toxicity of organic solvents, increased production process, high storage and transportation costs, and achieve the effects of simple method, easy drying and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

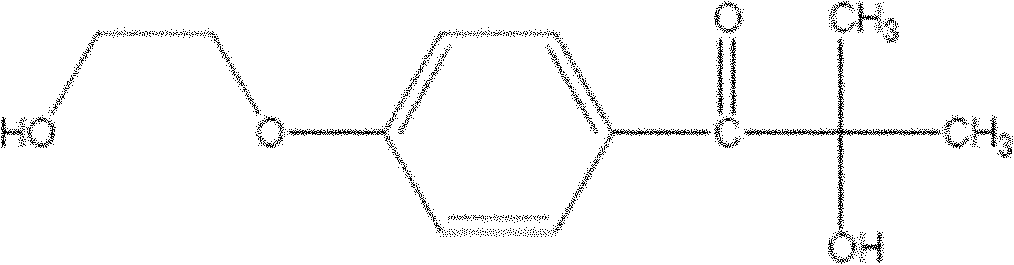

Embodiment 1

[0037] The photoinitiator Irgacure 2959 (10mmol / L), monomer acrylic acid (AA, 2.0mol / L), and acetone (20ml) were mixed in a self-made straight tube hard glass reaction flask to prepare a reaction solution (liquid layer thickness L=0.8 cm), seal the mouth of the bottle with a biaxially oriented polypropylene (BOPP) film, and pour high-purity nitrogen into the bottle for 20 minutes to remove oxygen in the solution; then place the reaction solution under a 250W straight tube medium pressure mercury lamp to irradiate (light Strong is 13W / m 2 ) 120min. The solvent is poured, the polymer is separated and dried. The measured monomer conversion rate is 99.6%, the polymer molecular weight is 2.82 million, and 0.5 g polymer sample can be dissolved in 10 ml deionized water within 10 minutes.

Embodiment 2

[0039] As in Example 1, the reaction solution was irradiated for 60 minutes, the monomer conversion rate was determined to be 92.8%, the polymer molecular weight was 2.65 million, and 0.5 g of the polymer sample could be dissolved in 10 ml of deionized water within 10 minutes.

Embodiment 3

[0041] The photoinitiator DMPA (0.1mmol / L), monomer acrylic acid (AA, 2.0mol / L), and acetone (20ml) were mixed in a self-made straight tube hard glass reaction flask to form a reaction solution (liquid layer thickness L=0.8 cm), seal the mouth of the bottle with a biaxially oriented polypropylene (BOPP) film, and pour high-purity nitrogen into the bottle for 20 minutes to remove oxygen in the solution; then place the reaction solution under an 8W straight tube low-pressure mercury lamp to illuminate (light intensity 16W / m 2 ) 120min. The solvent is poured, the polymer is separated and dried. The measured monomer conversion rate was 91.7%, the polymer molecular weight was 3.4 million, and a 0.5g polymer sample could be dissolved in 10ml deionized water within 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com