Polymerization method of perylene diimide fluorochrome

A technology of polymerization and peryleneimide, which is applied in the field of polymerization preparation of peryleneimide fluorescent dyes, can solve the problems of weakening solid-state emission, being difficult to dissolve, and difficult to disperse, and achieves improved solubility and high preparation efficiency. , the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail.

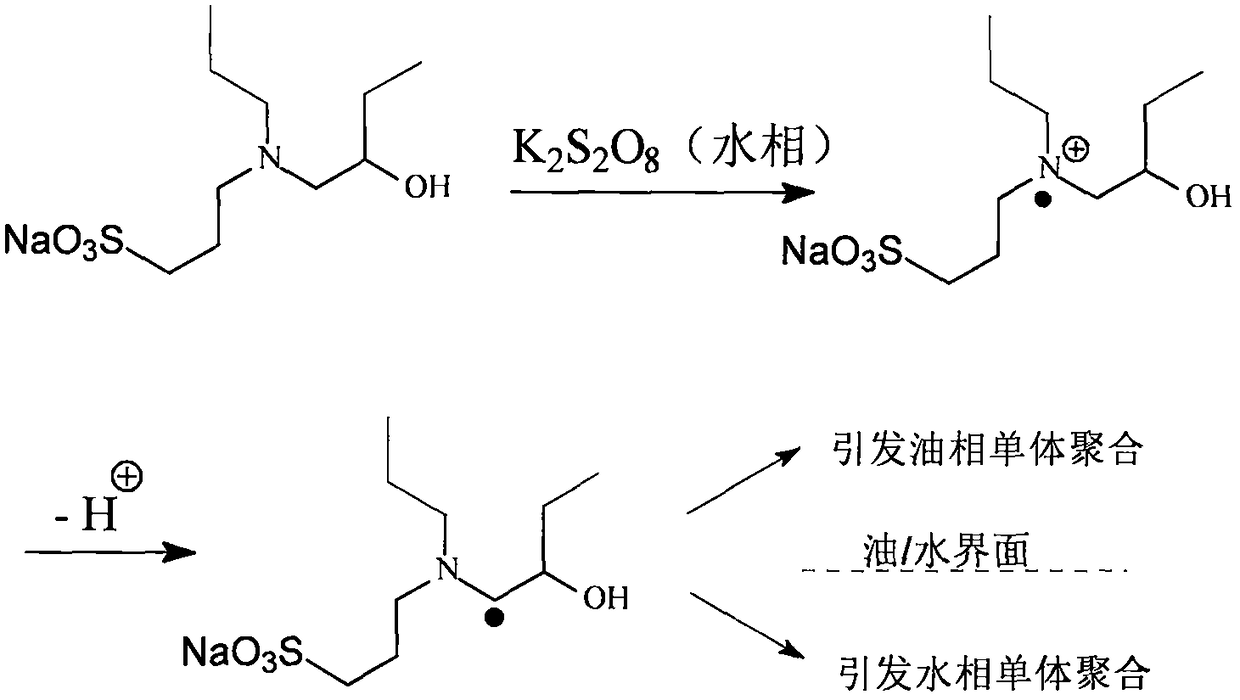

[0021] Preparation of functional initiators:

[0022] With perylene imide as the starting raw material, there is a ready-made method for the preparation of this raw material compound, which will not be repeated here. The following are the specific preparation steps:

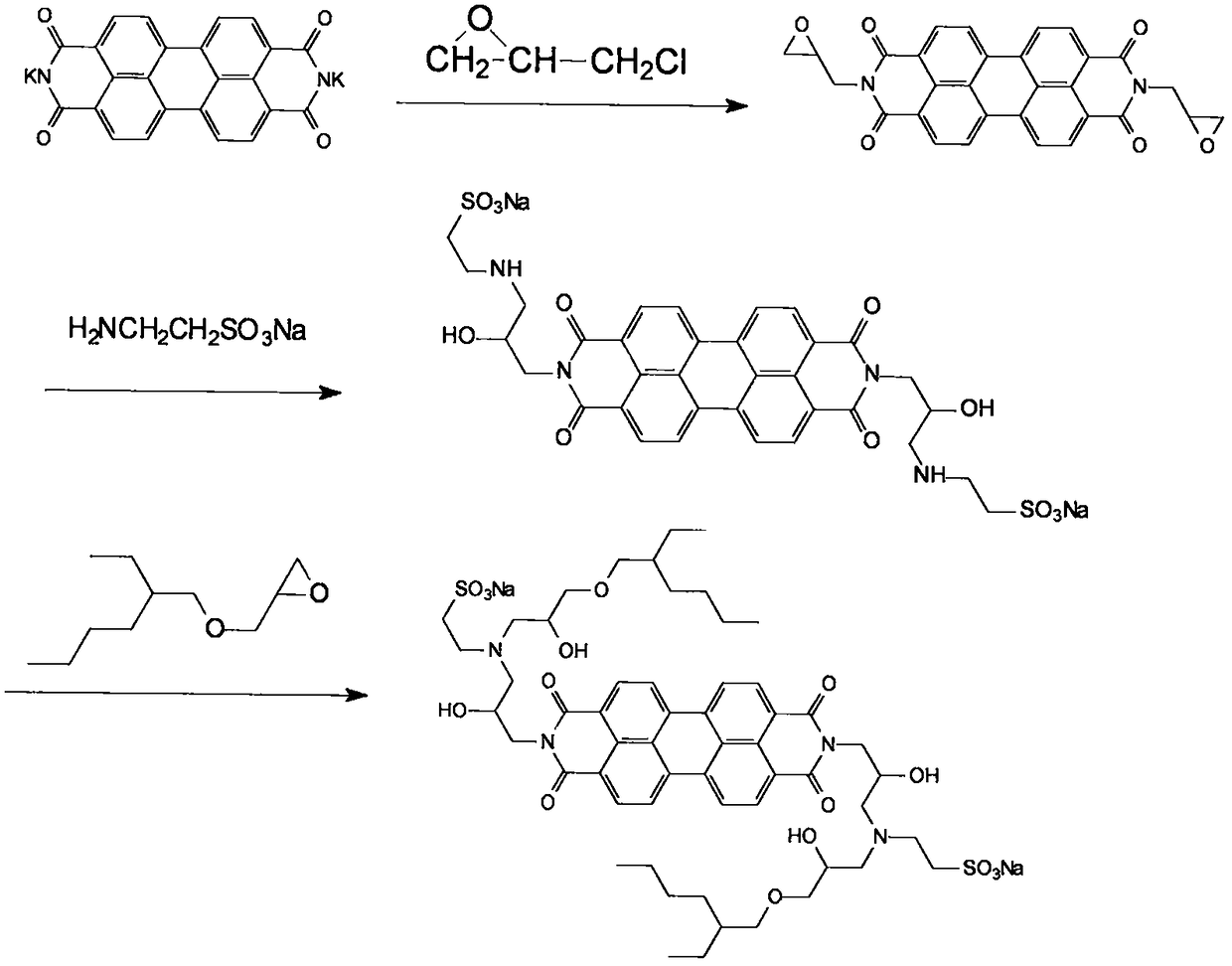

[0023] 1) Dissolve 0.1mol of peryleneimide and 0.2mol of KOH in 800ml of water, add 0.3mol of epichlorohydrin under stirring, heat and reflux for 4 to 5 hours, the product is continuously precipitated from the water phase, after the reaction is completed Cool to room temperature, collect the precipitated substance by filtration and wash with water several times to remove the generated potassium chloride, and then wash with methanol to remove excess epichlorohydrin;

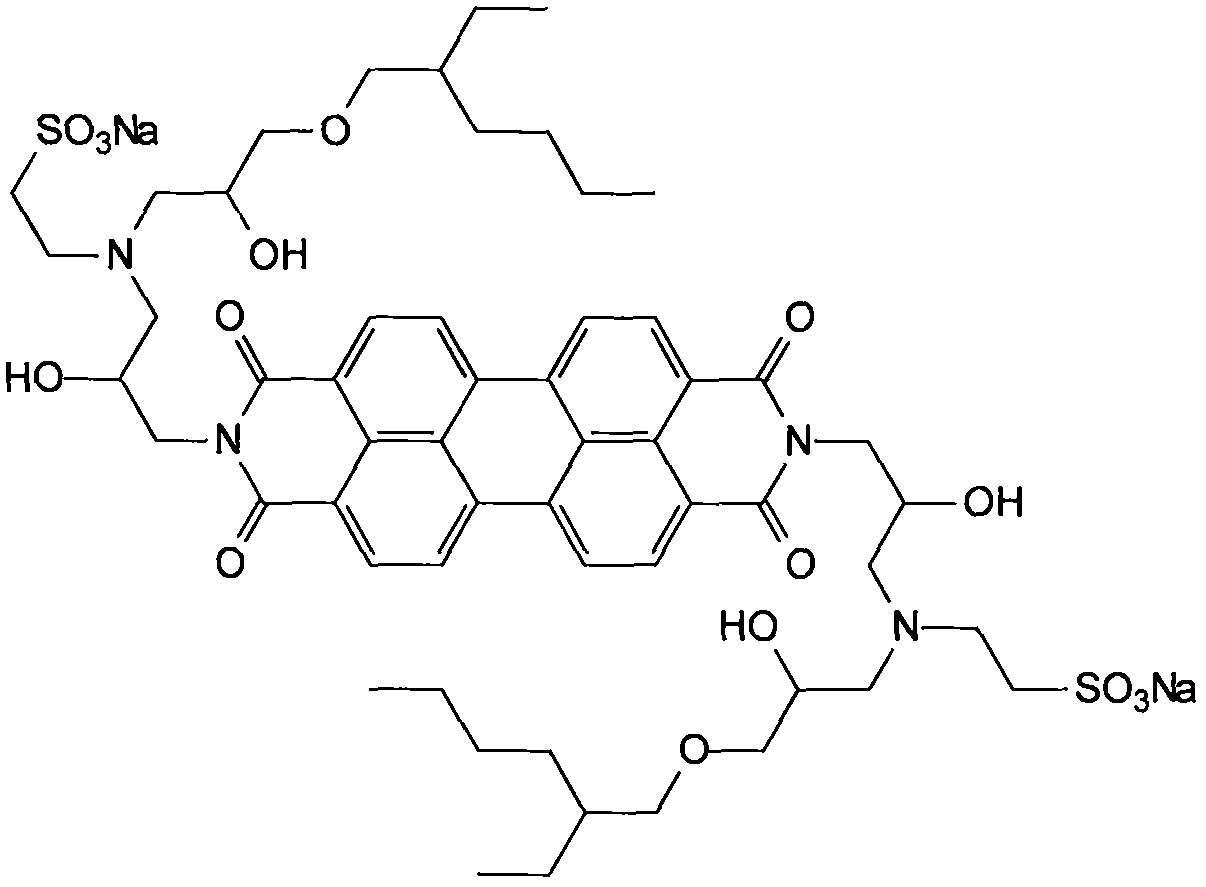

[0024] 2) Redisperse the product obtained in the previous step reaction in 800ml of water, then add 0.25mol of sodium taurate, and control the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com