Preparation method of antimony-doped tin oxide nano-powder

An antimony-doped tin oxide and nano-powder technology is applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, which can solve the problems of uneven powder doping, complex process routes, and difficulty in removing impurities, and achieve calcination temperature. Low, simple process, the effect of speeding up the polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

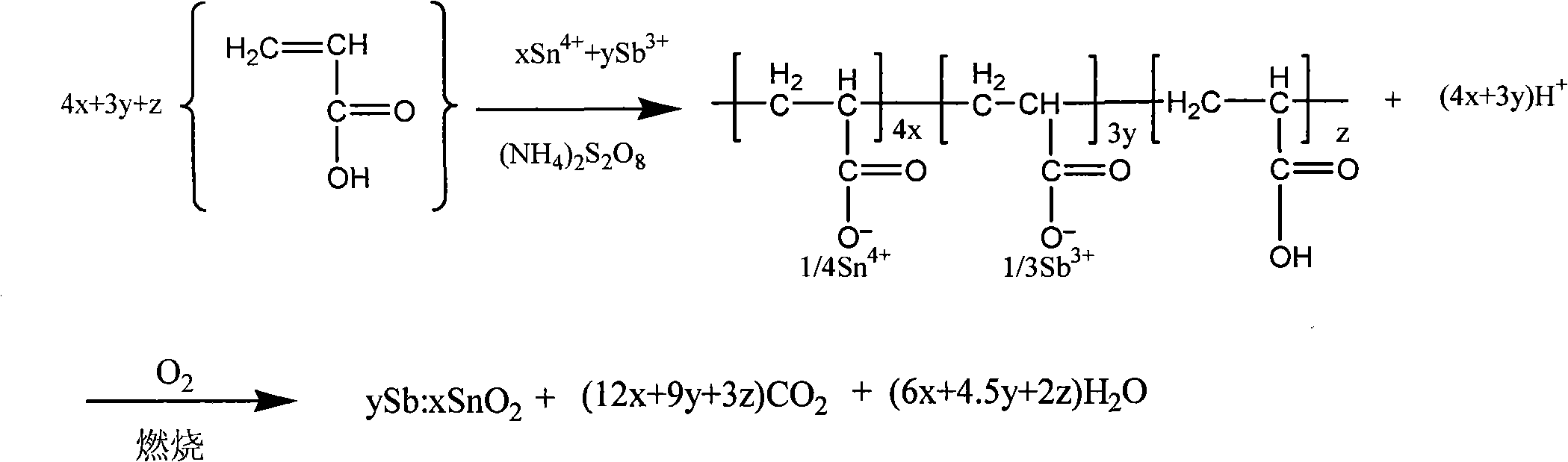

[0018] ① Dissolve 4 parts by weight of acrylic acid in 1 part by weight of deionized water, and fully dissolve under magnetic stirring to obtain solution A;

[0019] ②Fix the ratio of tin tetrachloride and solution A by weight to 5:100, weigh antimony trichloride and tin tetrachloride in a molar ratio of 5:100, add them into the above solution A, and obtain under magnetic stirring Homogeneous system B;

[0020] 3. Under magnetic stirring conditions, the aqueous solution of 5% ammonium persulfate is slowly added to step 2. in the homogeneous system B prepared by weight percentage to obtain solution C; The weight ratio is 0.01:1;

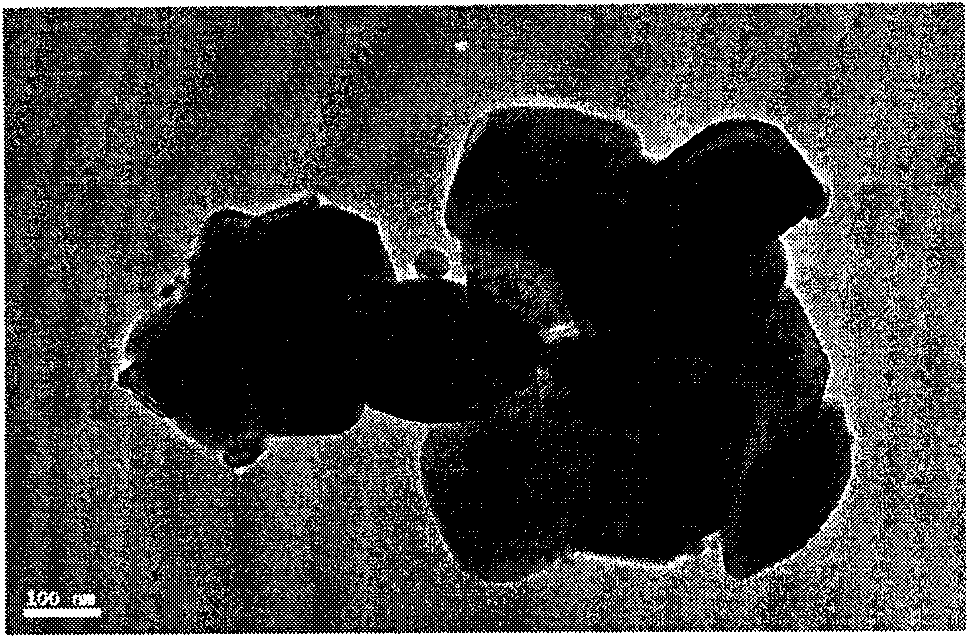

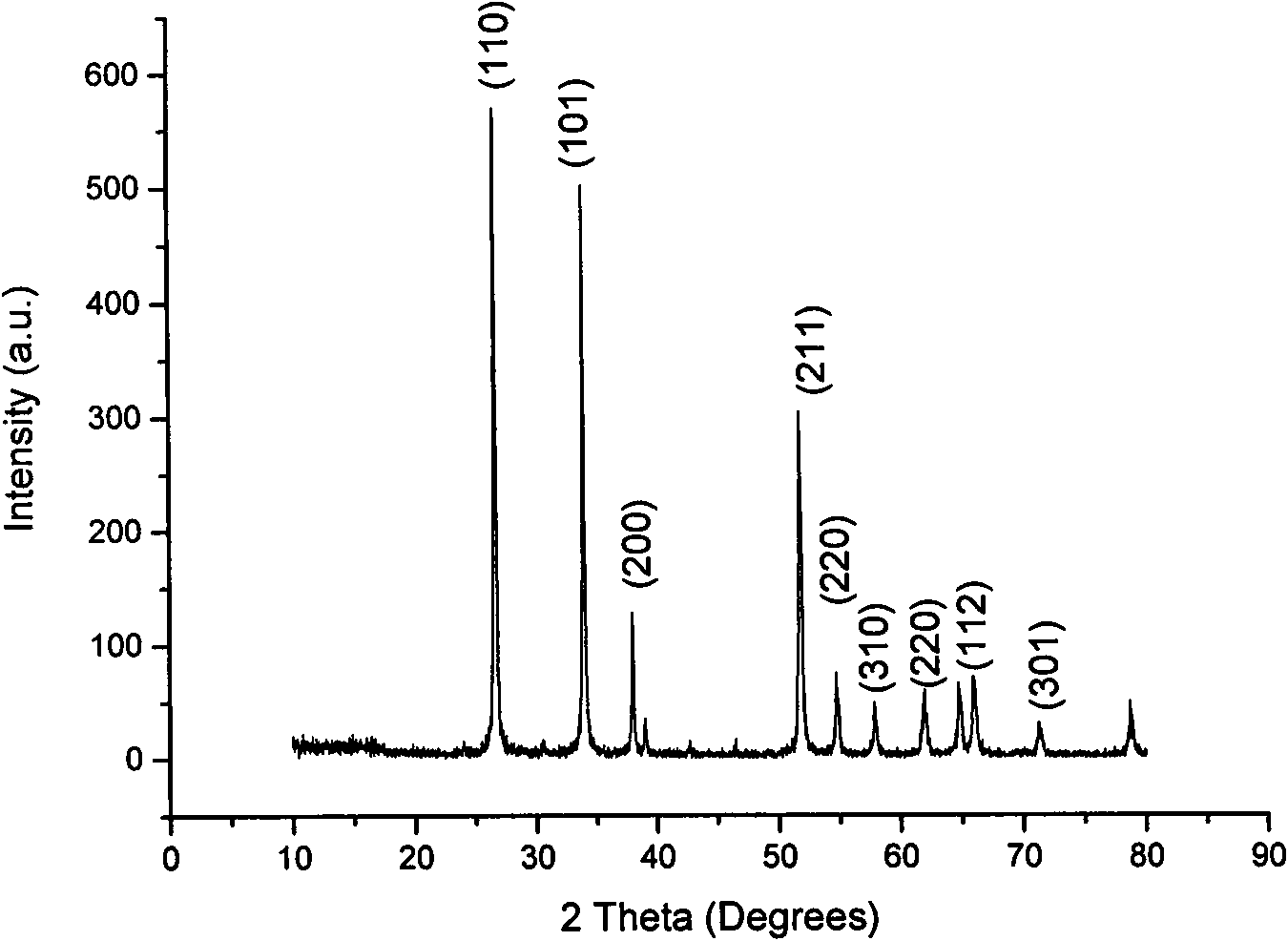

[0021] ④Heat the solution C obtained in step ③ at 100°C for 1h to complete the polymerization of the system; then dry at 80°C for 24h to obtain a solid; after cooling, grind it, then place it in a muffle furnace, and in an air atmosphere at 700°C, After calcining for 3 hours, the light gray blue antimony-doped tin oxide nanopowder was prepared.

[...

Embodiment 2

[0025] ①Dissolve 1 part by weight of acrylic acid in 1 part by weight of deionized water, and fully dissolve under magnetic stirring to obtain solution A;

[0026] ② Fix the ratio of tin tetrachloride and solution A by weight to 1:100, weigh antimony trichloride and tin tetrachloride in a molar ratio of 15:100, add them to the above solution A, and obtain under magnetic stirring Homogeneous system B;

[0027] 3. under magnetic stirring conditions, the deionized aqueous solution of 10% ammonium persulfate by weight percentage is slowly added in step 2. in the homogeneous system B that makes, obtains solution C; The ammonium persulfate added and step 1. in The weight ratio of acrylic acid is 0.05: 1;

[0028] ④Heat the solution C obtained in step ③ at 60°C for 3h to complete the polymerization of the system; then dry at 110°C for 10h to obtain a solid; after cooling, grind it, and then place it in a muffle furnace under the condition of air atmosphere and 450°C. Calcined for 1...

Embodiment 3

[0031] ①Dissolve 2 parts by weight of acrylic acid in 1 part by weight of deionized water, and fully dissolve it under magnetic stirring to obtain solution A;

[0032] ②Fix the weight ratio of tin tetrachloride to solution A at 25:100, weigh antimony trichloride and tin tetrachloride in a molar ratio of 1:100, add them to the above solution A, and obtain a homogeneous solution under magnetic stirring. System B;

[0033] 3. Under magnetic stirring conditions, the aqueous solution of 2% ammonium persulfate is slowly added to step 2. in the homogeneous system B prepared by weight percentage to obtain solution C; The weight ratio is 0.1:1;

[0034] ④Heat the C solution obtained in step ③ at 80°C for 0.1 hour to complete the polymerization of the system; then dry it at 150°C for 5 hours to obtain a solid; after cooling, grind it, and then place it in a muffle furnace, under the condition of air atmosphere and 900°C After calcination for 1 h, the light gray blue antimony-doped tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com