Method for recovery of contaminated groundwater through in situ enhanced aeration

An in-situ strengthening, groundwater technology, applied in chemical instruments and methods, water aeration, water/sludge/sewage treatment, etc., can solve the problems of limiting pollutant removal efficiency, slow pollutant removal, and high tailing concentration. Achieve faster removal rate, lower cost, and less environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

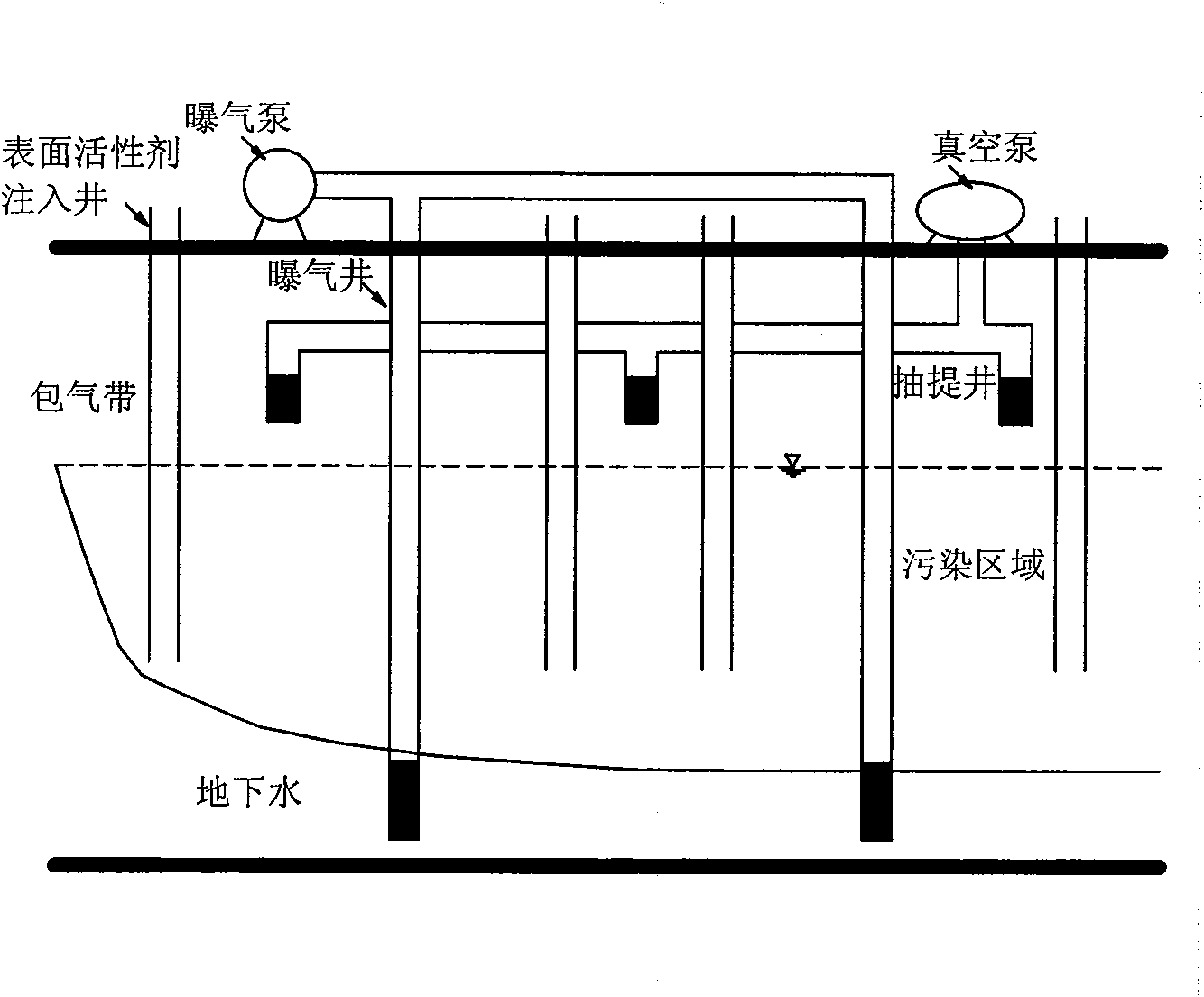

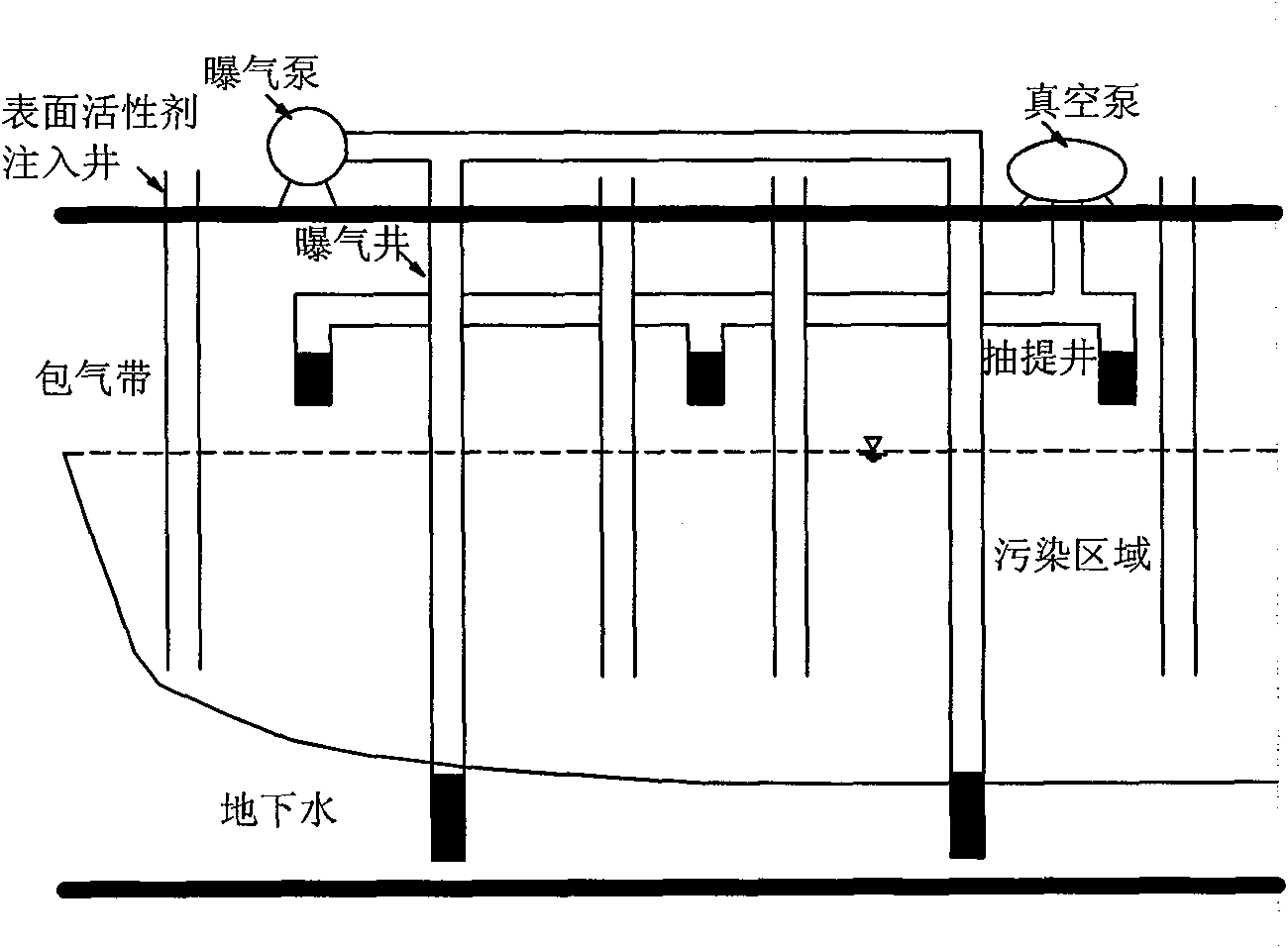

[0025] a. Drill 4 surfactant injection wells in the groundwater polluted area. The distance between the injection wells is 5m. For the polluted groundwater layer, three extraction wells should be drilled, the distance between the extraction wells is 5m, the extraction wells do not penetrate the vadose zone, and the bottom of the well is close to the groundwater surface in the vadose zone; the aeration wells and extraction wells are arranged in Surfactant injection between wells;

[0026] b. Connect the surfactant storage tank to the surfactant injection well through the pipeline, connect the aeration pump to the aeration well through the pipeline, and connect the extraction well to the extraction pump through the pipeline;

[0027] C, anionic surfactant sodium dodecylbenzene sulfonate is injected into the amount of 400mg / liter per liter of groundwater, injected into the groundwater polluted area by injection pump, sodium dodecylbenzenesulfonate is dissolved in groundwater, in ...

Embodiment 2

[0031] a. Drill 3 surfactant injection wells in the groundwater polluted area. The distance between the injection wells is 3m. For the polluted groundwater layer, two extraction wells should be drilled, the distance between the extraction wells is 2m, the extraction wells do not penetrate the vadose zone, and the bottom of the well is close to the groundwater surface in the vadose zone; the aeration well and the extraction well are arranged in Surfactant injection between wells;

[0032] b. Connect the surfactant storage tank to the surfactant injection well through the pipeline, connect the aeration pump to the aeration well through the pipeline, and connect the extraction well to the extraction pump through the pipeline;

[0033] c. Inject the anionic surfactant sodium lauryl sulfate at 200mg / liter per liter of groundwater into the groundwater polluted area through an injection pump, so that sodium lauryl sulfate dissolves in the groundwater and forms a surface in the ground...

Embodiment 3

[0037] a. Drill 6 surfactant injection wells in the groundwater polluted area. The distance between the injection wells is 7m. For the polluted groundwater layer, 5 extraction wells should be drilled, the distance between the extraction wells is 7m, the extraction wells do not penetrate the vadose zone, and the bottom of the well is close to the groundwater surface in the vadose zone; the aeration wells and extraction wells are arranged in Surfactant injection between wells;

[0038] b. Connect the surfactant storage tank to the surfactant injection well through the pipeline, connect the aeration pump to the aeration well through the pipeline, and connect the extraction well to the extraction pump through the pipeline;

[0039] c. The non-ionic surfactant Tween 80 is injected into the groundwater polluted area by the injection pump at the amount of 100mg / liter per liter of groundwater, so that the surfactant Tween 80 is dissolved in the groundwater, and the surface tension for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com