Method for preparing o-cresol

A technology for o-cresol and phenol, applied in the field of preparing o-cresol, can solve the problem of low selectivity of o-cresol, and achieve the effects of long service life, low selectivity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Catalyst preparation: Weigh Fe(NO 3 ) 3 9H 2 O 404g, Mg(NO 3 ) 2 ·6H 2 O 51.2g and Ce(NO 3 ) 3 ·6H 2 O 2.17g was mixed and dissolved in 800mL ethanol, and then it was slowly mixed with 28% concentrated ammonia water 700mL containing 4g PEG in a co-current manner under normal temperature ultrasonic conditions, and the ultrasonic wave was continued for 30min after the addition, and then the precipitate was filtered. Wash and dry at 120°C for 6h. The obtained solid is then roasted at 450°C for 8 hours, and finally the solid is ground into fine particles, and then crushed into small particles of 10 to 20 meshes after tableting. The obtained basic metal oxide catalyst is Fe 1 Mg 0.2 Ce 0.05 / o.

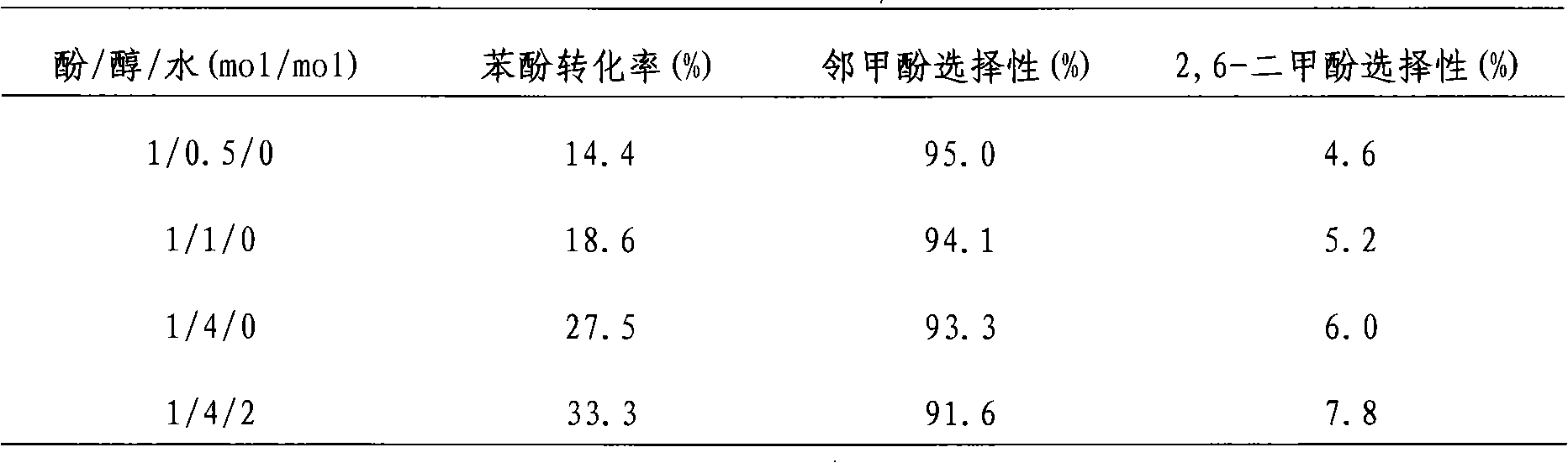

[0027] The above-mentioned catalyst was packed in a Φ7mm stainless steel reaction tube, the catalyst loading amount was 5g, the reaction mixture was metered in with an advection pump, and the temperature was controlled by a temperature control device. Feed space velocity...

Embodiment 2

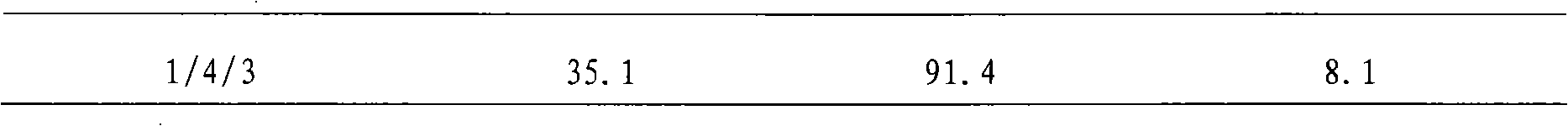

[0032] Catalyst is with embodiment 1. Reaction mixture phenol / methanol / water=1 / 4 / 3 (mol / mol), carrier gas helium flow rate is 30mL / min, changes reaction temperature, other conditions are with embodiment 1, reacted 12 hours sampling and carried out chromatographic analysis, o-formazan The phenol selectivity is above 89.5%, and the ortho position selectivity is above 99.1%. The results are shown in Table 2.

[0033] Table 2 changes the result of reaction temperature synthesis o-cresol

[0034]

Embodiment 3

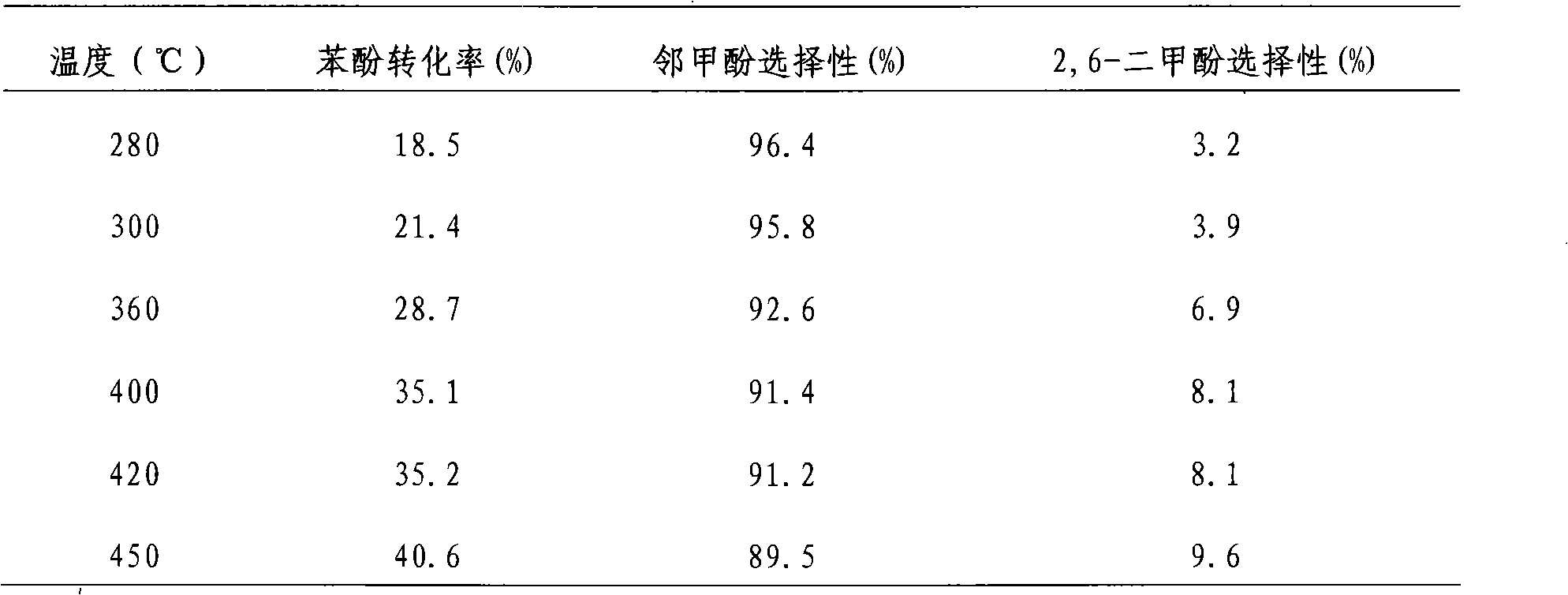

[0036] Catalyst is with embodiment 1. Reaction mixture phenol / methanol / water=1 / 4 / 3 (mol / mol), change feeding space velocity, other conditions are with embodiment 1, react 12 hours sampling and carry out chromatographic analysis, o-cresol selectivity is more than 89.7%, o-cresol The position selectivity is above 99.2%, and the results are shown in Table 3.

[0037] Table 3 changes the result of feed space velocity synthesis o-cresol

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com