Method for synthesizing tricyclic decane unsaturated monoaldehyde

A tricyclodecane and unsaturated technology, which is applied in the field of synthesizing tricyclodecane unsaturated monoaldehyde, can solve the problems of low monoaldehyde selectivity, complex reaction system, and high reaction temperature, and achieve simple reaction system and high preparation process. The effect of simplicity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

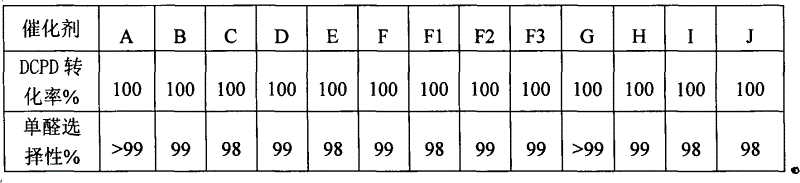

Image

Examples

Embodiment 1

[0029] Preparation of Ferromagnetic Oxide Iron Tetroxide Directly Supporting Metal

[0030] a, under strong stirring, 50mmol (20.2g) Fe(NO 3 ) 3 9H 2 O and (0.1 g) RhCl 3 ·3H 2 O was dissolved in 100mL distilled water, then added dropwise to 330mL (0.47mol / L) Na 2 CO 3 In the aqueous solution, the precipitation temperature is 20°C, and the whole process takes about 1 hour. The precipitate is vacuum filtered and centrifuged, and the precipitate is washed with distilled water to neutrality. The metal hydroxide supported by iron hydroxide formed by precipitation is in the Dry at 120°C for 16 hours to obtain a brown solid;

[0031] b. Roasting the brown solid in step a at a temperature of 400° C., the roasting time is 4 hours, and the roasting atmosphere is air;

[0032] c. Reducing and activating the roasted solid in step b with hydrogen as a reductant at a temperature of 400° C. for 1 hour to obtain about 4 g of rhodium metal supported by ferromagnetic oxide ferric oxide;...

Embodiment 2

[0038] Preparation of Ferromagnetic Oxide Iron Tetroxide Directly Supporting Metal

[0039] Under vigorous stirring, 50mmol (20.2g) Fe(NO 3 ) 3 9H 2 O and (0.1 g) RhCl 3 ·3H 2 O was dissolved in 100mL of distilled water, and then added dropwise to 330mL (0.47mol / L) NaOH aqueous solution. The precipitation temperature was 40°C. The whole process took about 1 hour. The precipitate was vacuum filtered and centrifuged, and the precipitate was washed with distilled water. To neutrality, the metal hydroxide supported by iron hydroxide formed by precipitation was dried at a temperature of 80 ° C for 6 hours to obtain a brown solid;

[0040] b. Roasting the brown solid in step a at a temperature of 200° C., the roasting time is 4 hours, and the roasting atmosphere is nitrogen;

[0041] c. Reducing and activating the roasted solid in step b with hydrogen as a reductant at a temperature of 200° C. for 6 hours to obtain about 4 g of rhodium metal supported by ferromagnetic oxide tri...

Embodiment 3

[0047] Preparation of Ferromagnetic Oxide Iron Tetroxide Directly Supporting Metal

[0048] Under vigorous stirring, 50mmol (20.2g) Fe(NO 3 ) 3 9H 2 O and (0.1 g) RhCl 3 ·3H 2 O, 0.1g of cobalt nitrate was dissolved in 100mL of distilled water, and then added dropwise to 330mL (0.47mol / L) of ammonia solution, the precipitation temperature was 20°C, and the whole process took about 1 hour, and the precipitate was vacuum filtered and centrifuged. The precipitate was washed with distilled water to neutrality, and the iron hydroxide-supported metal hydroxide formed by precipitation was dried at a temperature of 100° C. for 8 hours to obtain a brown solid;

[0049] b. Roasting the brown solid in step a at a temperature of 300° C., the roasting time is 5 hours, and the roasting atmosphere is air;

[0050] c. The solid roasted in step b is activated by hydrogen reduction with a reducing agent at a temperature of 300° C. for 2 hours to obtain about 4 g of cobalt-rhodium bimetal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com