Unsaturated polyesters

An unsaturated, polyester technology that is used in polyester coatings, chemical instruments and methods, polishing compositions, etc., and can solve problems such as accurate grading that has not yet been adopted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0208] Embodiment 1 (polyester)

[0209] 3.3 mol tricyclodecane dimethanol mixture, 2.1 mol phthalic anhydride and 1.1 mol maleic anhydride were reacted in a reaction flask equipped with a distillation unit, a stirrer and a thermometer at 210° C. under a nitrogen atmosphere until reaching 15.9 mg KOH / g acid value and 36.0 mg KOH / g OH number.

[0210] m n =2100g / mol M w = 7200 g / mol, polydispersity = 3.4, glass transition temperature 62°C (no crystallization peak), as a 60% solution in xylene, viscosity 960 mPa·s, as a 60% solution in xylene , Garnder color value before / after heat load is 0.1 / 0.2, benzene content: <2mg / kg, formaldehyde content: <1mg / kg.

Embodiment 2

[0211] Embodiment 2 (polyester)

[0212] 5.3 mol tricyclodecane dimethanol mixture, 2.5 mol adipic acid and 2.5 mol maleic anhydride were reacted in a reaction flask equipped with distillation unit, stirrer and thermometer under nitrogen atmosphere at 210°C until 28 mg KOH / g acid value and 29 mg KOH / g OH number.

[0213] m n =2000g / mol M w =5200g / mol, polydispersity=2.6, glass transition temperature 9°C (no crystallization peak), as a 60% solution in xylene, viscosity 780mPa·s, as a 60% solution in xylene , Garnder color value before / after heat load is 0.1 / 0.1, benzene content: <2mg / kg, formaldehyde content: <1mg / kg.

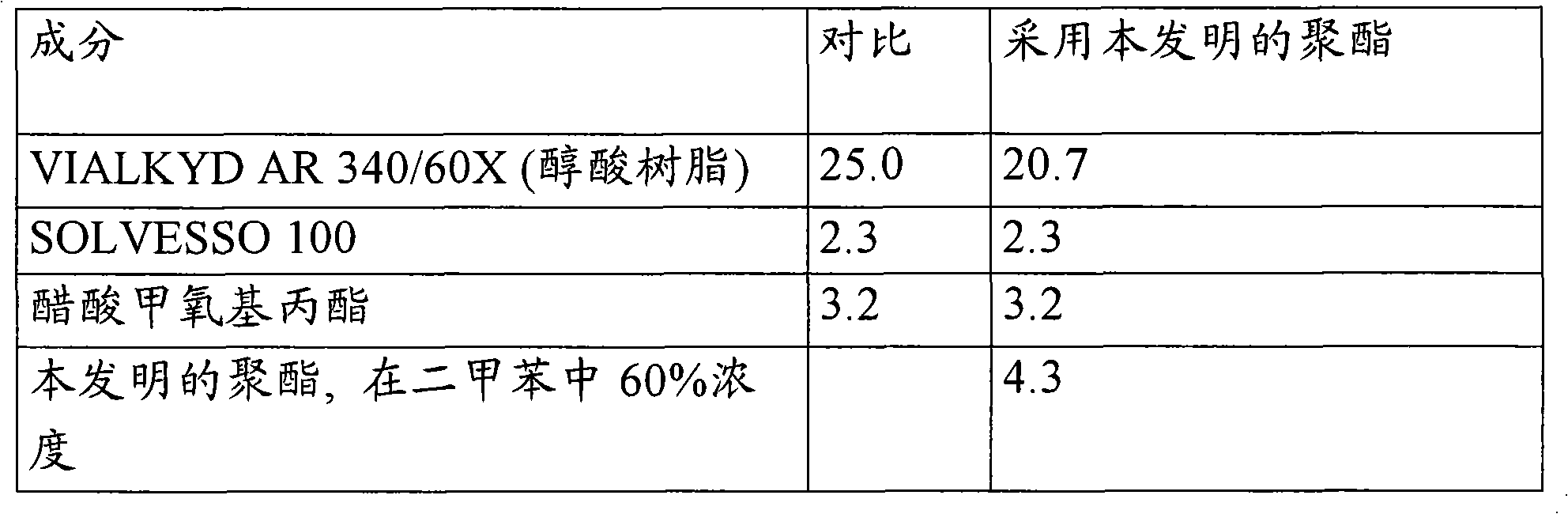

[0214] The compatibility of the two inventive polyesters of Examples 1 and 2 was investigated. It has high compatibility with, for example, PVC, chlorinated rubber, nitrocellulose, ketone-aldehyde resins, alkyd resins, acrylate resins, polyesters, melamine resins, urea resins and polyisocyanates.

[0215]Resistance to yellowing under climatic conditions wa...

Embodiment 3

[0218] Embodiment 3 (polyester)

[0219] Put 9.9 mol tricyclodecane dimethanol mixture, 5.0 mol phthalic anhydride, 2.0 mol adipic acid and 3.0 mol maleic anhydride in a reaction flask equipped with a distillation unit, a stirrer and a thermometer at 210 ° C under a nitrogen atmosphere The reaction was carried out until the acid value of 32mgKOH / g and OH number of 27mgKOH / g were reached.

[0220] m n =2000g / mol M w =5900g / mol, polydispersity=3.0, glass transition temperature 46°C (no crystallization peak), as a 60% solution in xylene, viscosity 850mPa·s, as a 60% solution in xylene , Garnder color value before / after heat load is 0.1 / 0.2, benzene content: <2mg / kg, formaldehyde content: <1mg / kg.

[0221] The polyester of the present invention thus prepared was melted at about 120° C. in a closed container, mixed with dimethylethanolamine corresponding to a degree of neutralization of 1.0, and water was supplied, and vigorously stirred. Cooling to room temperature provided a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com