Magnesium compound load type non-metallocene catalyst and preparation thereof

A magnesium compound, non-metallocene technology, applied in the field of magnesium compound supported non-metallocene catalysts, can solve the problems of low olefin polymerization activity, high vacuum, unsuitable for industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

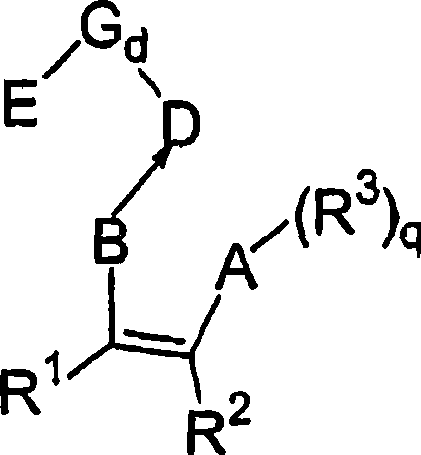

[0110] First, the present invention relates to a preparation method of a magnesium compound-supported non-metallocene catalyst, comprising the following steps: contacting a magnesium compound with a chemical treatment agent selected from group IVB metal compounds to obtain a contact product, and using a non-metallocene The step of ligand processing the contact product to obtain the supported non-metallocene catalyst.

[0111] The magnesium compound is the carrier of the supported non-metallocene catalyst, such as magnesium halide, alkoxymagnesium halide, alkoxymagnesium, alkylmagnesium, alkylmagnesium halide, alkylalkoxymagnesium or Any one or a mixture of more.

[0112] Specifically, magnesium halide such as can be selected from magnesium chloride (MgCl 2 ), magnesium bromide (MgBr 2 ), magnesium iodide (MgI 2 ) and magnesium fluoride (MgF 2), etc., wherein magnesium chloride is preferred.

[0113] Alkoxymagnesium halides such as can be selected from methoxymagnesium chl...

Embodiment 1

[0281] Magnesium compound is anhydrous magnesium chloride (MgCl 2 ), the chemical treatment agent is titanium tetrachloride (TiCl 4 ).

[0282] Weigh 5g of anhydrous magnesium chloride, add 25ml of hexane as a solvent for the preparation of the contact product to disperse it, then add titanium tetrachloride dropwise for 30 minutes under stirring, react at 60°C for 4 hours, filter, wash with hexane for 3 times, 25ml each time, vacuum-dried to obtain the contact product. The molar ratio of titanium tetrachloride and magnesium compound was 1:2.

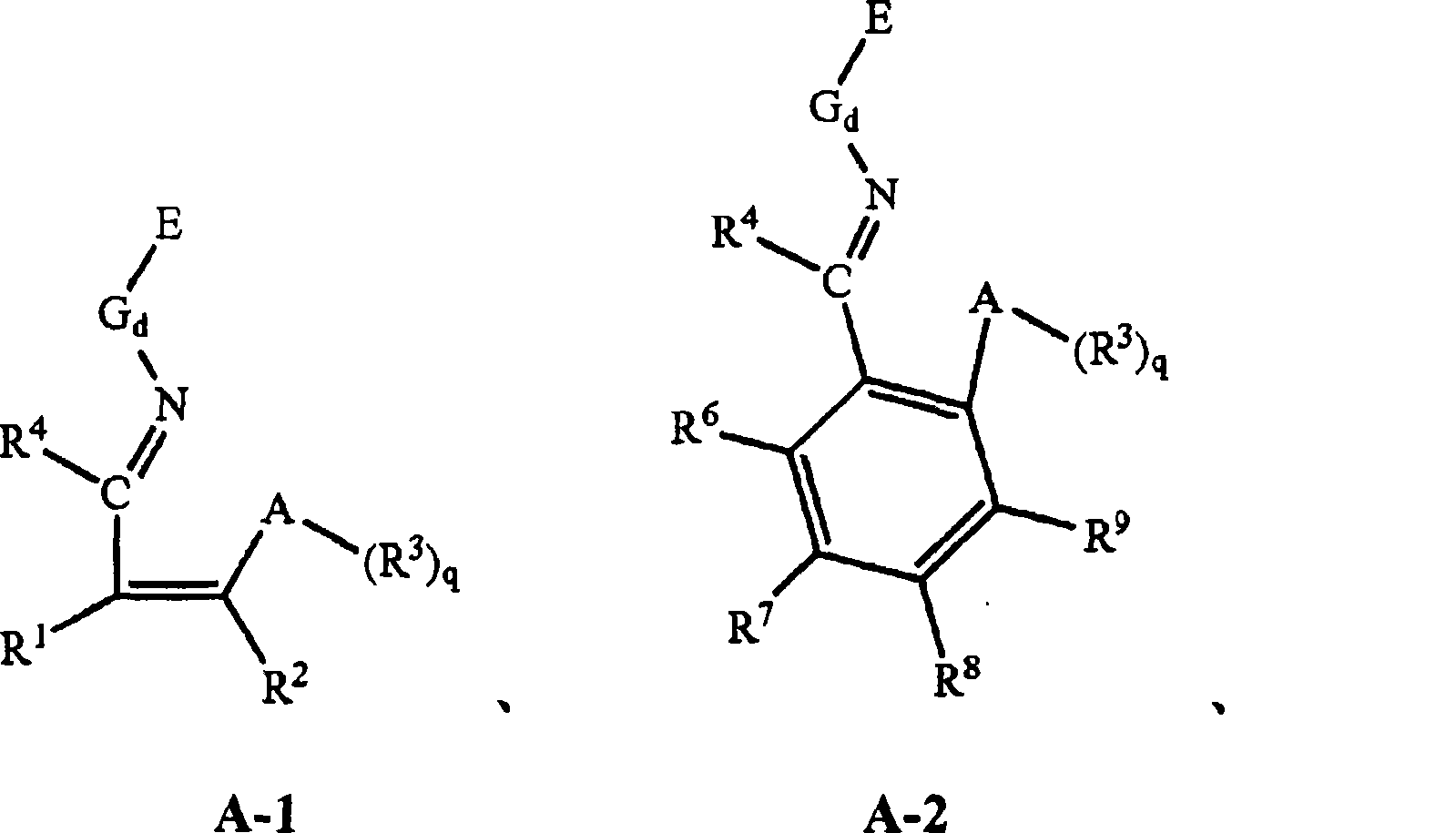

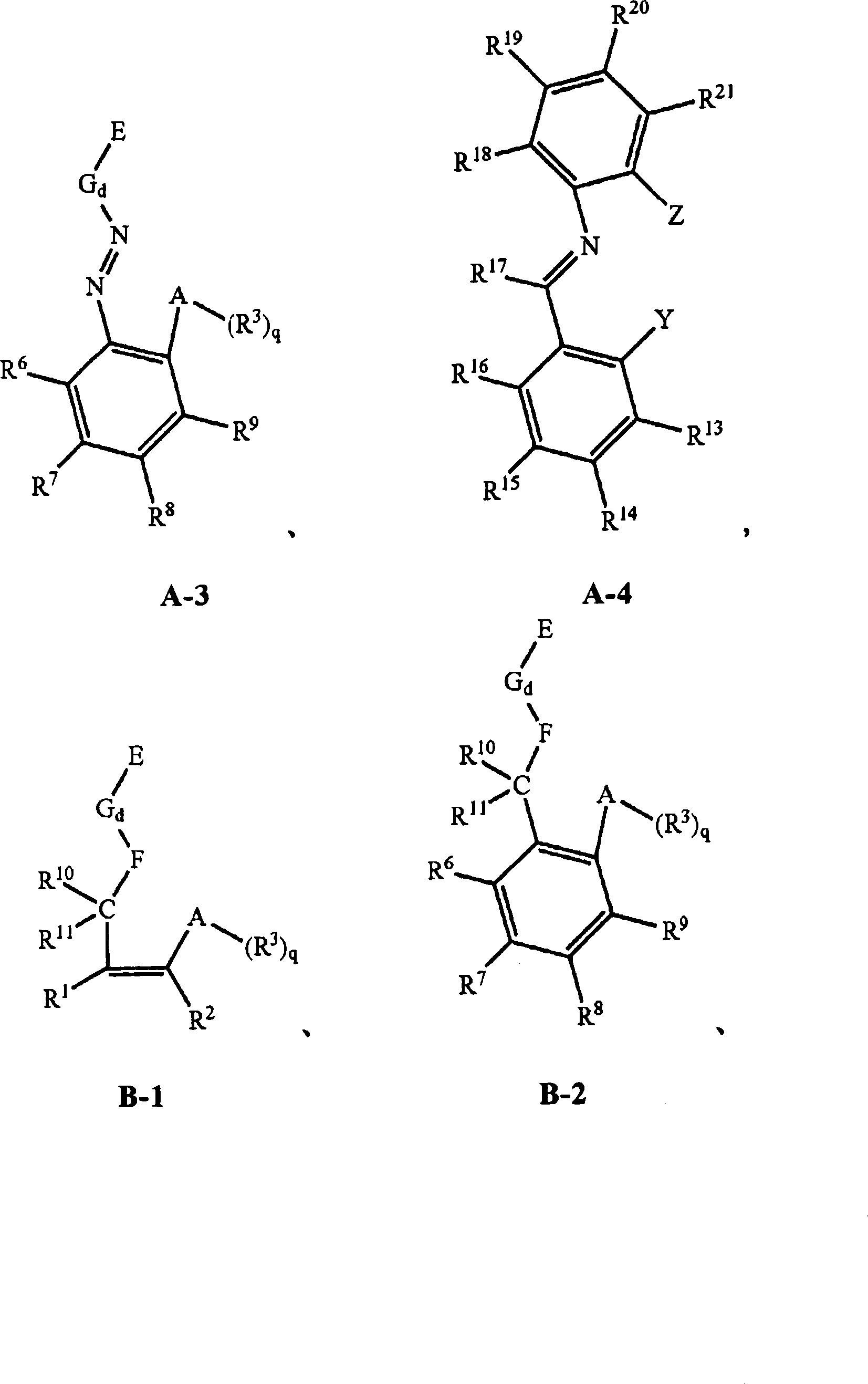

[0283] the structural formula The non-metallocene ligand is dissolved in hexane (ligand mass concentration is 100 g / liter), then add the contact product under stirring, filter after reacting for 4 hours, wash 2 times with hexane, each hexane consumption is 25ml, Then it was dried at 25 °C for 6 h to obtain the magnesium compound-supported non-metallocene catalyst.

[0284] The mass ratio of ligand to contact product is 0.11:1.

[0...

Embodiment 1-1

[0287] Basically the same as Example 1, but with the following changes:

[0288] The magnesium compound is changed to magnesium bromide (MgBr 2 ), the chemical treatment agent is titanium tetrabromide (TiBr 4 ), its molar ratio with the magnesium compound is 1:4.5.

[0289] The solvent used for the preparation of the contact product was changed to decane.

[0290] The non-metallocene ligand is changed to Dissolved in decane, the mass concentration of the ligand is 50 g / L, and the mass ratio of the ligand to the contact product is 0.22:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com