Concentrating method and device in acesulfame potassium production

Acesulfame-K, water-containing acesulfame-K technology, applied in the application, food preparation, food science and other directions, can solve the problems of high heater temperature and easy scaling, large energy loss, poor sugar color, etc. Reduced calorific value requirements and good chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

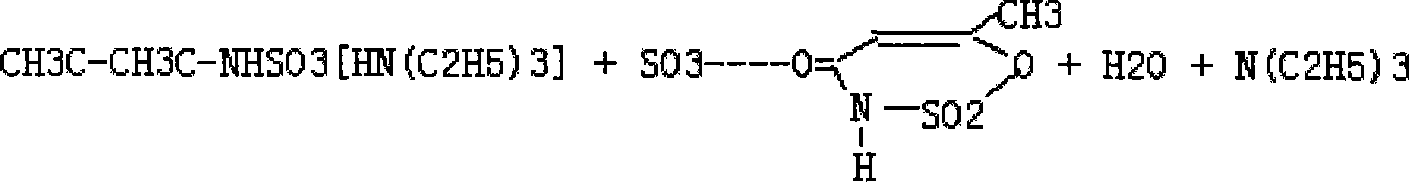

Method used

Image

Examples

example 1

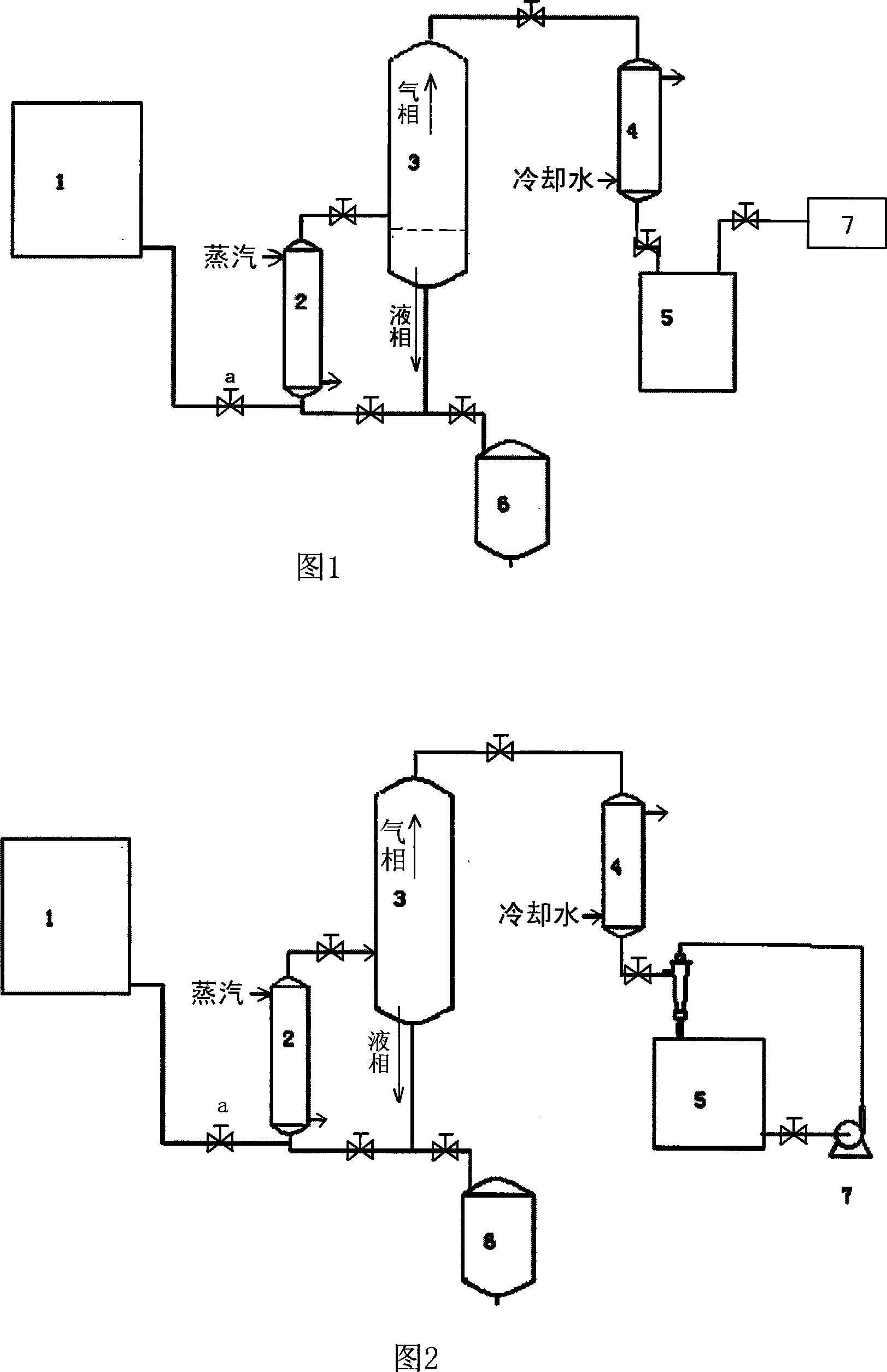

[0019] Example one: as shown in Figure 1, the concentrator of the present invention, its system structure is made up of: the upper end of evaporator (3) connects condenser (4) with pipeline, and the lower end of condenser (4) connects with pipeline The condensate tank (5) for storing condensate is connected with a plunger vacuum pump (7) with a pipeline on the condensate tank (5). The lower end of the evaporating tank (3) is connected with a freezing kettle (6) for storing concentrated acesulfame potassium with a pipeline. In addition, a heating tank (2) is provided, and its upper end is connected to the middle and lower part of the evaporation tank (3) with a pipeline, and the lower end of the heating tank (2) is connected in parallel with a sugar water tank (1) for storing acesulfame potassium and a storage tank for concentrated acesulfame. The freezing still (6) of honey, the bottom position of evaporating tank (3) is higher, should be near the heating tank (2) top, and the...

example 2

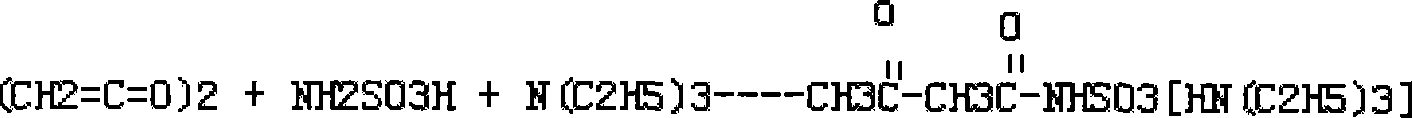

[0022] Example 2: As shown in Figure 2, the vacuum pump (7) adopts a water jet vacuum pump, fills the condensate tank (5) with appropriate soft water, and starts the water jet vacuum pump (7).

[0023] About 12% of the sugar water after the neutralization process is automatically pumped into the evaporation system by vacuum, and when it reaches a certain level, the heater is turned on to heat it. After being heated in the heater, the material rises by itself and enters the separator for vaporization and separation. The gas phase enters the condenser to collect condensed water, and the liquid phase circulates into the heater. Supplement sugar water to control the liquid level. When the vacuum degree is -0.06Mpa and 80°C, samples can be taken for analysis, and the material is passed to the freezer.

[0024] It can be completed in four hours without a batch, can process 10 cubic meters of sugar water, and produce about 1 ton of crude sugar.

[0025] The water jet vacuum pump is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com