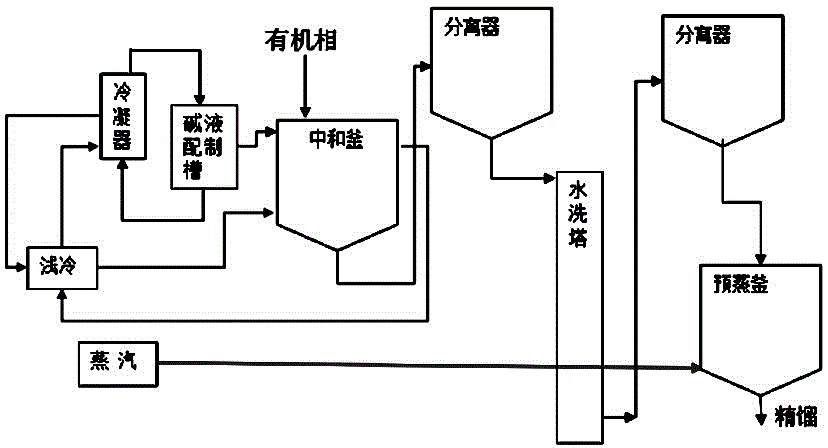

Method for solvent self-heating separation in acesulfame potassium synthesis

A separation method and acesulfame technology are applied in chemical instruments and methods, halogenated hydrocarbon disproportionation separation/purification, halogenated hydrocarbon preparation, etc. problems, to achieve the effect of simplifying operation, saving steam, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

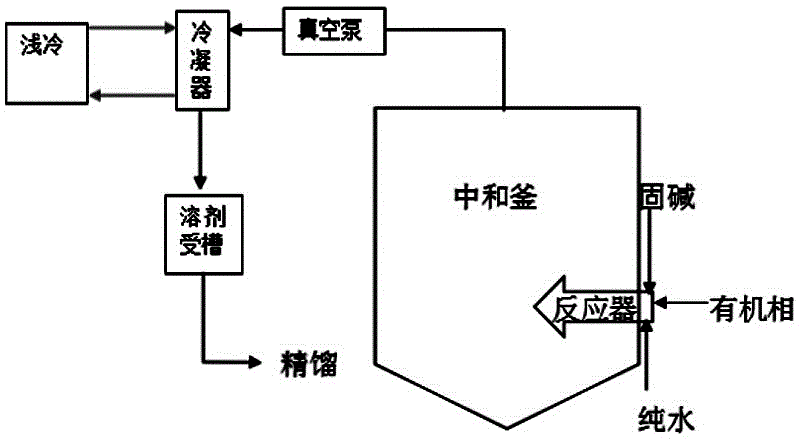

[0016] Such as figure 2 As shown, the present invention provides a solvent self-heating separation method in the synthesis of acesulfame potassium, utilizes the exothermic heat of dissolution and reaction, pressurizes in the reactor, depressurizes after going out of the reactor, reduces the boiling point of the solvent, and makes dichloro Methane evaporates quickly after passing through the reactor, and is condensed and recovered to replace the original standing separation, water washing, re-separation, pre-steaming and other processes

[0017] Specific steps:

[0018] 7) Pump 0.6t / h of solid potassium hydroxide and 5t / h of water into the reactor first, so that the temperature of the neutralization tank will naturally rise to 60°C.

[0019] 8) Turn on the vacuum pump to pump the neutralization tank to a negative pressure of -0.4mpa.

[0020] 9) Dilute the organic phase to 10m 3 / h is pumped into the reactor and the temperature in the kettle decreases first and then increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com