Acesulfame potassium synthesis section acylation reaction process

A technology of synthesis reaction and acylation process, which is applied in the field of acylation reaction process of acesulfame potassium synthesis process, which can solve the problems of increased process difficulty, increased reaction time, and slow reaction speed, so as to shorten reaction time, improve production efficiency, and increase temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

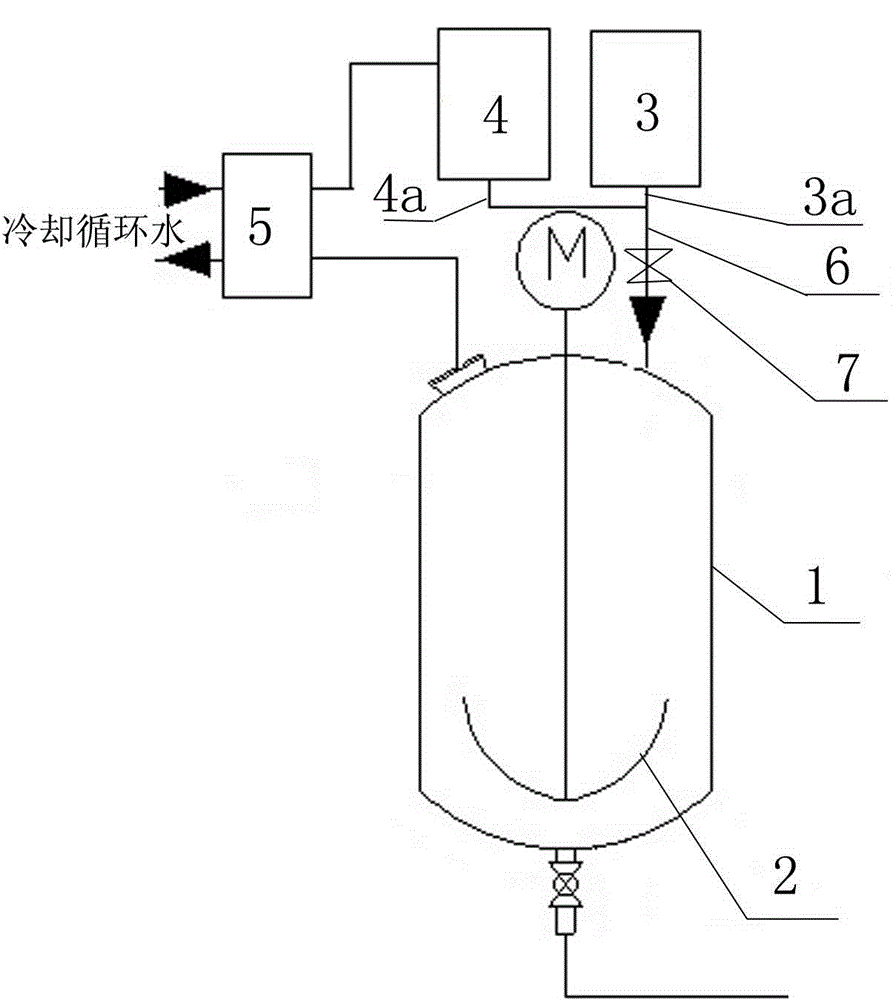

[0013] Such as figure 1 As shown, the present invention provides a kind of acylation reaction process of acesulfame potassium synthesis section, comprising the following steps:

[0014] a) Turn on the agitator 2 of the acylation kettle 1 and the circulating water flowing through the plate heat exchanger 5;

[0015] b) Put the synthetic reaction product of sulfamic acid and triethylamine in the acylation kettle 1;

[0016] c) Mix dichloromethane and diketene with a volume ratio of 1:1 evenly, and drop the mixture of dichloromethane and diketene into the acylation kettle according to the batching amount, and the dripping flow rate is 500L / H; specifically, a connecting pipe 6 can be set , the connecting pipe 6 communicates with the outlet pipe 4a of the dichloromethane tank 4 and the outlet pipe 3a of the diketene tank 3 respectively, and a regulating valve 7 is set on the connecting pipe 6 to realize mixing and flow regulation;

[0017] d) The vaporized dichloromethane returns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com