Method for continuously producing acesulfame potassium

A continuous, cyclizing agent technology, applied in the direction of organic chemistry, can solve the problem of difficult stability of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

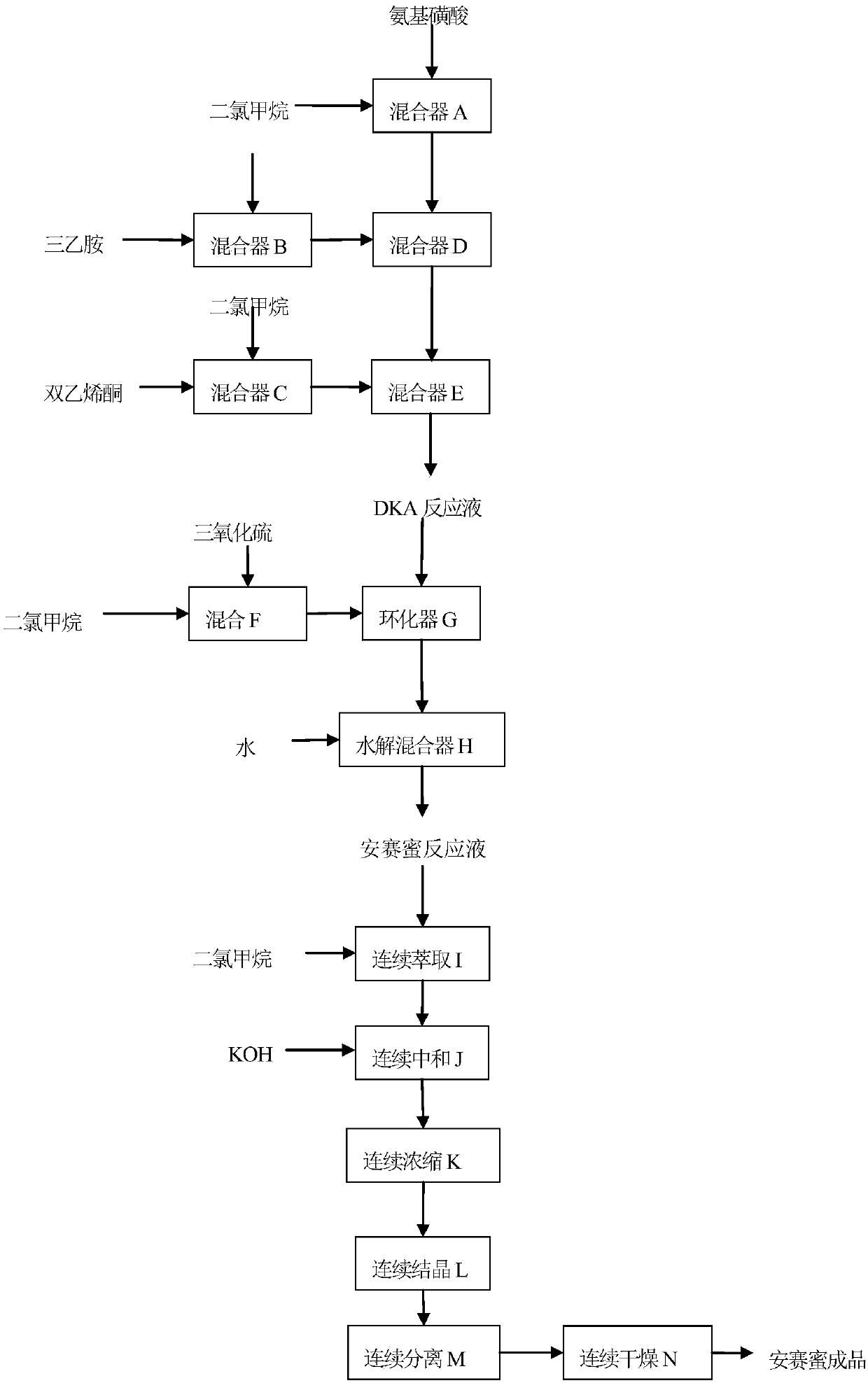

[0043] A method for continuous production of acesulfame K, comprising the steps of:

[0044] (1) Acylation section

[0045]1. Sulfamic acid and dichloromethane are continuously mixed and dissolved, and then continuously neutralized with triethylamine solution. The neutralization reaction solution and diketene enter the continuous reactor, and the DKA reaction solution is obtained through addition acylation reaction.

[0046] 2. The continuous mixing and dissolving, the molar ratio is: n (sulfamic acid): n (dichloromethane 1: 1 ~ 20, preferably 1: 8 ~ 12; the temperature is 0 ~ 40 ° C; preferably 15 ~ 25 ℃;

[0047] 3. The continuous neutralization, wherein neutralized pH=7~9; its triethylamine solution is a mixed solution of triethylamine and dichloromethane, and the molar ratio is n (triethylamine):n (dichloromethane) =1:0~5, preferably 1:0~2; neutralization temperature is 10°C~40°C, preferably 20°C~30°C.

[0048] 4. The addition acylation reaction, its molar ratio n(sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com