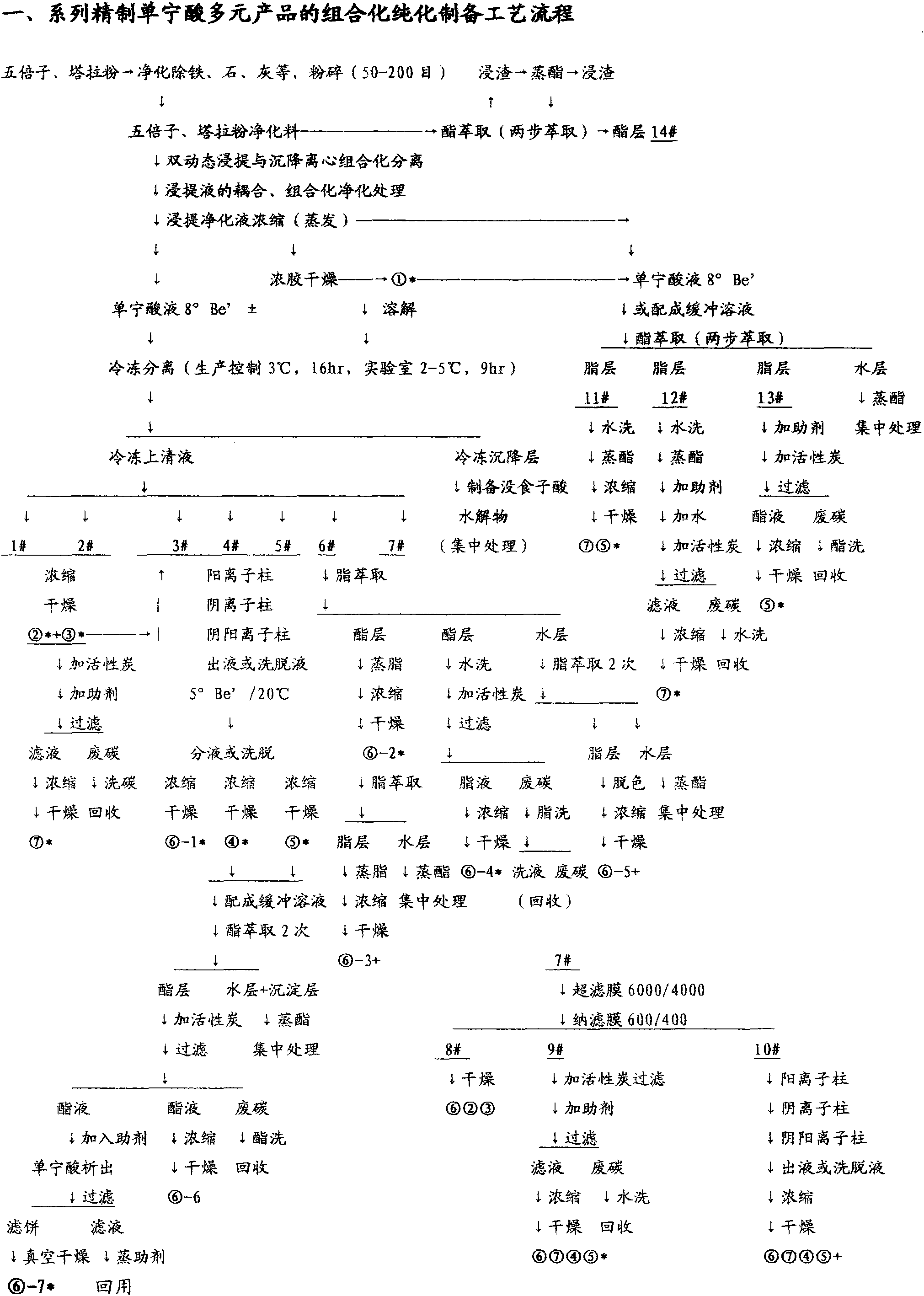

Multielement combined purification preparation process of refined tannic acid serie and combined preparation of products

A preparation process and technology of tannic acid, applied in the separation/purification of carboxylic acid compounds, preparation of carboxylic acid esters/lactones, separation/purification of carboxylic acid esters, etc., can solve the problem of limited application, can not reflect the superiority, solubility Obstacles and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

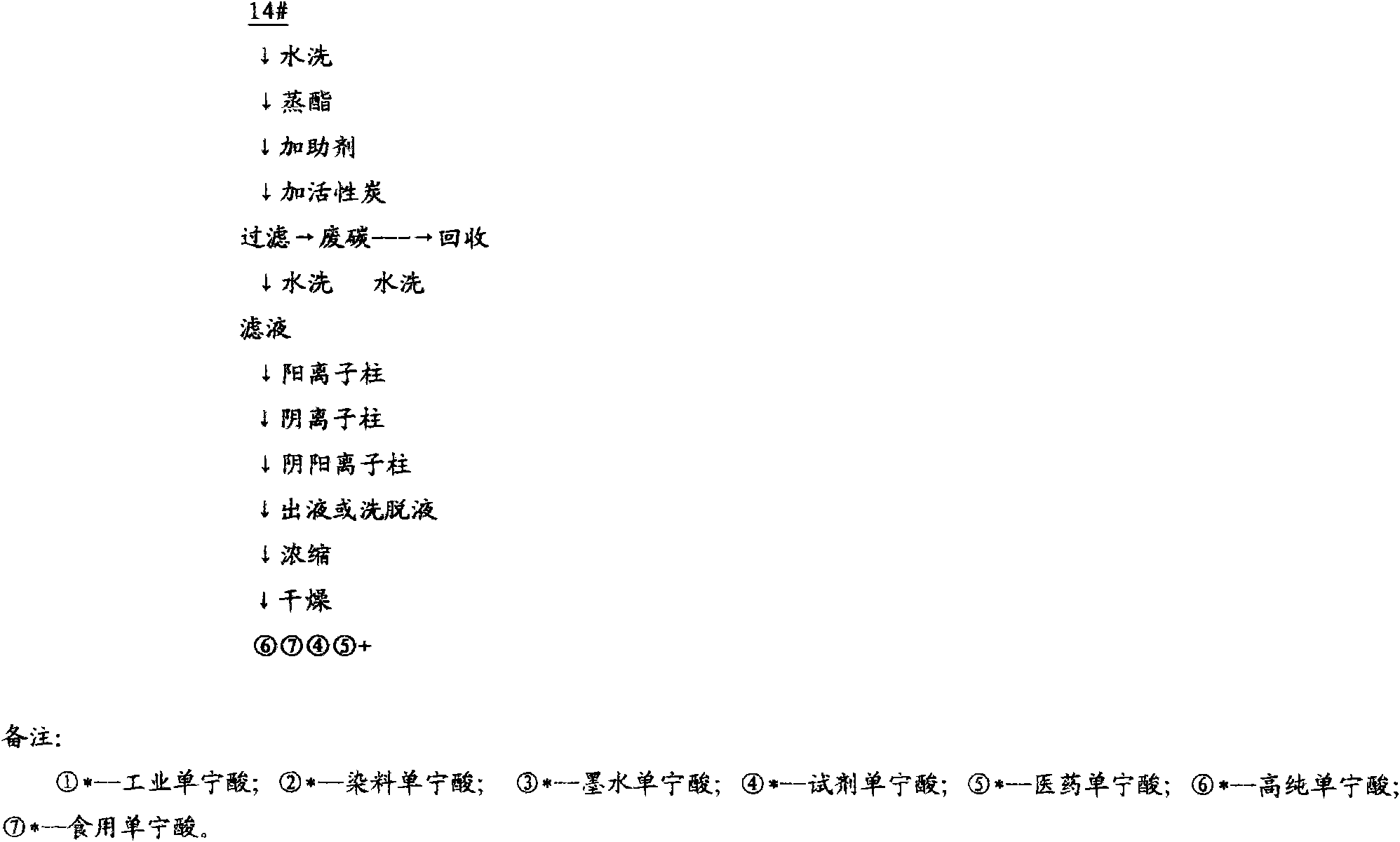

[0075] A series of refined tannic acid multi-component combined purification preparation process and combined preparation of its products are characterized by including the following steps:

[0076] In the first step, the selection of raw materials for the combined preparation of a series of refined tannic acid multi-products is gall or tara powder or industrial tannic acid prepared therefrom. The raw materials of Chinese gall include belly, jiao, and flower. It is required that the air-dried raw material of Galla Chinensis is pulverized by a plant pulverizer or the pulverization degree of the raw material after supplementary pulverization is 50-200 mesh.

[0077] In the second step, a series of refined tannic acid multi-combination purification preparation process and the combined preparation of its products are based on gall or Tara ultra-fine pulverization ratio material or industrial tannic acid prepared therefrom as raw materials, through multi-combination purification Proces...

Embodiment 2

[0112] The raw materials for the combined preparation of a series of refined tannic acid multi-products are gall or tara powder or industrial tannic acid prepared therefrom. The raw materials of Chinese gall include belly, jiao, and flower. It is required that the air-dried raw material of Galla Chinensis is pulverized by a plant pulverizer or the pulverization degree of the raw material after supplementary pulverization is 50-200 mesh.

[0113] The extraction of gall or Tara ultra-fine crushing ratio materials adopts dual dynamic extraction, sedimentation and centrifugal separation process.

[0114] The extraction process of gallic powder is based on the three-tank three-step process, atmospheric pressure extraction, the extraction temperature is 45~50℃, the concentration of the solution: 4~5°Be' / 20℃, the ratio of the extraction solution: one step 1:5, two Step 1:4, three steps 1:3; extraction temperature: 30~42℃ in one step, 42~50℃ in two steps, 50~60℃ in three steps; extraction...

Embodiment 3

[0120] Take the purified liquid of the extract of Galla Chinensis and Tara powder, and concentrate it to 7~10°Be′ / 20℃ under vacuum and reduced pressure, or use Galla Chinensis or Tara industrial tannic acid with distilled water or purified water to prepare 7~10°Be ' / 20℃ tannic acid solution.

[0121] Take the above 7~10°Be′ / 20°C Galla Chinensis, Tara powder extract purified liquid or tannic acid solution, cool to room temperature and then freeze with -10°C freezing solution to 0~5°C still freeze 16 After ~48hr, separate the upper clear liquid or the lower precipitation layer.

[0122] The supernatant liquid separated from the extract by freezing is about 7±2°Be′. One can be concentrated and spray-dried to prepare dye tannic acid or ink tannic acid; the other can be combined with other processes to prepare other tannic acid series product.

[0123] The lower layer liquid obtained by freezing and separating the extract is concentrated for gallic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulverization | aaaaa | aaaaa |

| Motor power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com