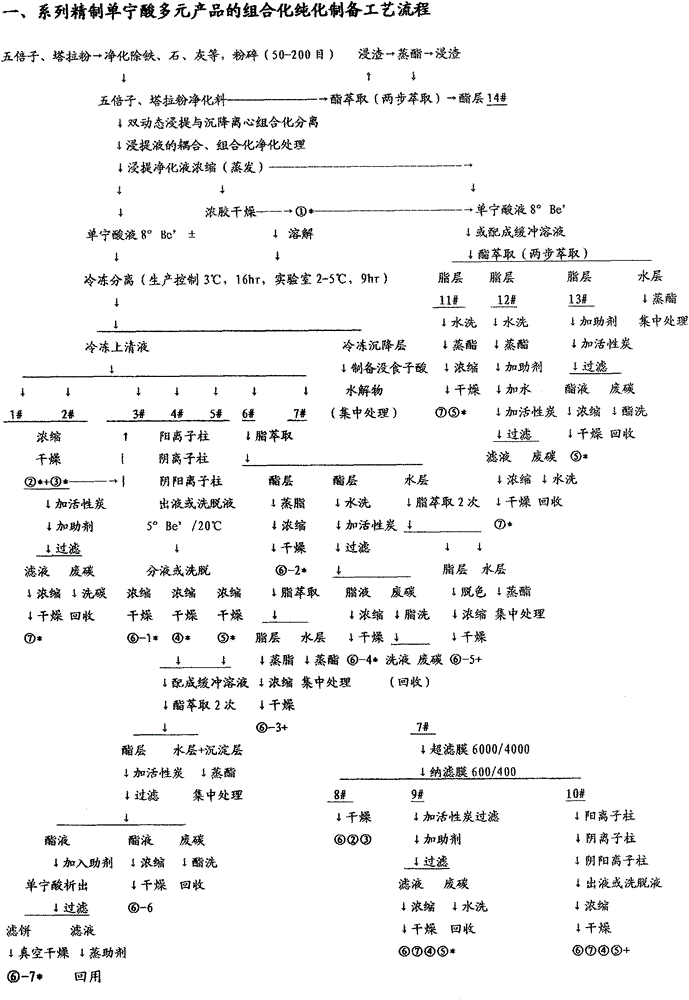

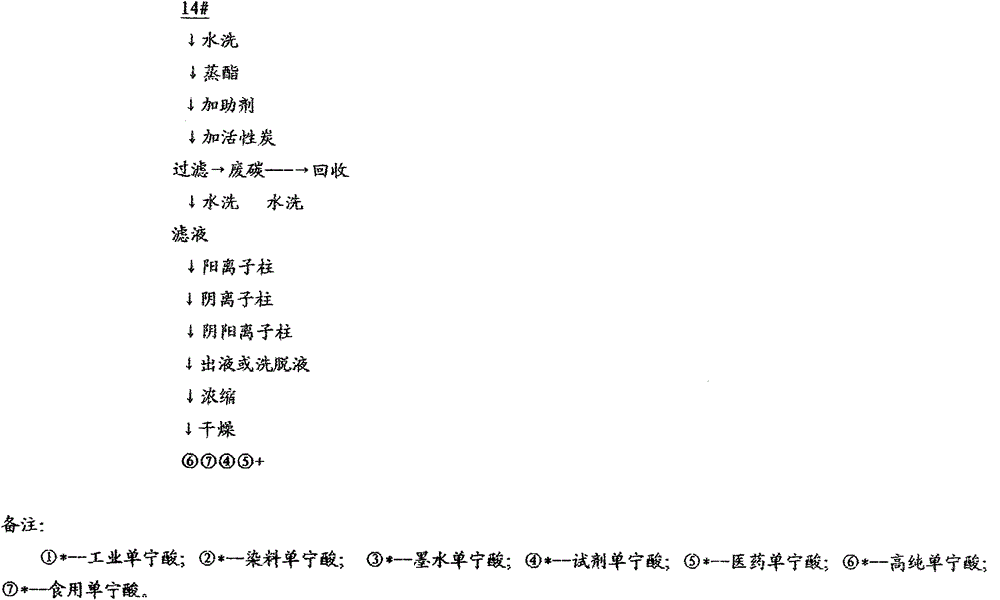

A series of refined tannic acid multi-combined purification preparation process and combined preparation of its products

A preparation process and technology of tannic acid, applied in the separation/purification of carboxylic acid compounds, preparation of carboxylic acid esters/lactones, separation/purification of carboxylic acid esters, etc. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A series of refined tannic acid multi-component purification preparation process and the combined preparation of its products are characterized in that it includes the following steps:

[0076]In the first step, the choice of raw materials for the combined preparation of a series of refined tannic acid multivariate products is gallnut or tara powder material or industrial tannic acid prepared therefrom. The raw materials of gallnut include belly times, horn times and times of flowers. It is required that the air-dried gallnut raw material be pulverized by a plant pulverizer or supplemented with purchased Tara powder so that the pulverization degree of the raw material is 50-200 mesh.

[0077] The second step, the series of refined tannic acid multi-combination purification preparation process and the combined preparation of its products are based on gallnut or tara ultra-fine crushed material or industrial tannin prepared from it as raw materials, through multi-combinat...

Embodiment 2

[0124] The choice of raw materials for the combined preparation of a series of refined tannic acid multivariate products is gallnut or tara powder material or industrial tannic acid prepared therefrom. The raw materials of gallnut include belly times, horn times and times of flowers. It is required that the air-dried gallnut raw material be pulverized by a plant pulverizer or supplemented with purchased Tara powder so that the pulverization degree of the raw material is 50-200 mesh.

[0125] The extraction of gallnut or Tara superfine crushed material adopts double dynamic extraction and sedimentation centrifugal separation process.

[0126] Gallnut powder extraction process is based on three-pot three-step process, atmospheric pressure extraction, extraction temperature 45-50 ° C, solution concentration: 4-5 ° Be' / 20 ° C, extraction ratio: one step 1:5, two Step 1:4, three steps 1:3; extraction temperature: one step 30~42℃, second step 42~50℃, third step 50~60℃; extraction t...

Embodiment 3

[0132] Take the purified solution of gallnut and tara powder extracts, concentrate under vacuum to 7-10°Be' / 20°C, or use gallnut or tara industrial tannic acid to add distilled water or pure water to prepare 7-10°Be ' / 20°C tannic acid solution.

[0133] Take the purification solution or tannic acid solution of the above-mentioned 7-10°Be' / 20°C gallnut and tara powder extract, cool to room temperature and then freeze it with -10°C freezing liquid to 0-5°C for 16 After ~48hr, separate the supernatant liquid or the lower precipitated layer.

[0134] The supernatant liquid extracted by freezing and separating is about 7±2°Be′, one of which can be concentrated and spray-dried to produce dye tannic acid or ink tannic acid; the other can be combined with other processes to prepare other tannic acid series product.

[0135] The lower layer liquid separated by freezing the extraction liquid is concentrated to be used as gallic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com