A multi-functional wide-flow high-efficiency gas-liquid separation device combining gravity and centrifugal technology

A gas-liquid separation device and combined technology, used in separation methods, dispersed particle separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

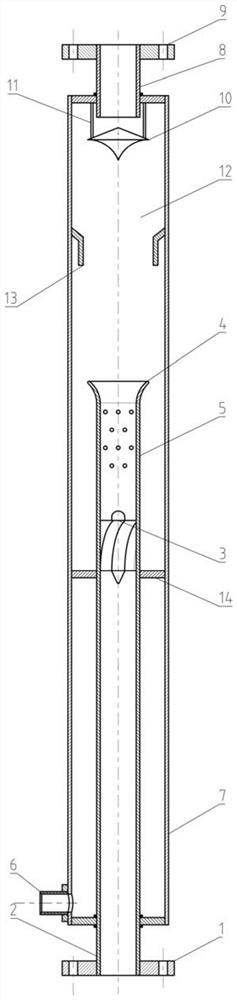

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

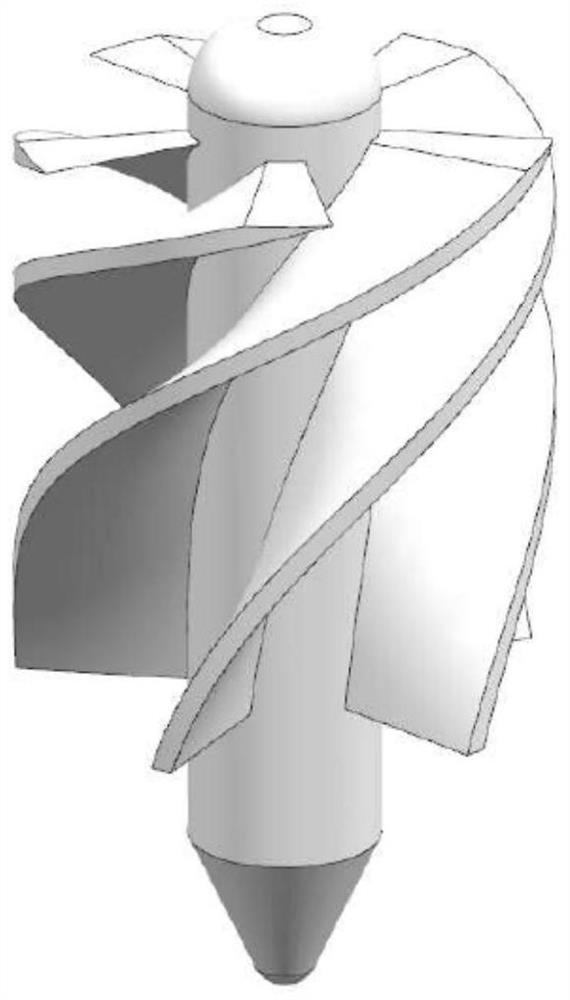

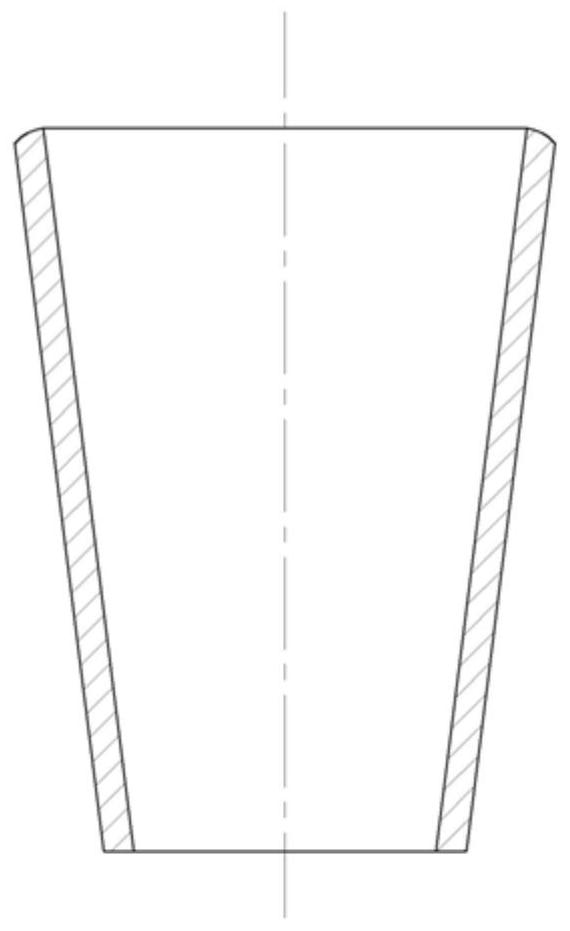

[0027] combine Figure 1-4 , the present invention is a multi-functional, wide-flow and high-efficiency gas-liquid separation device combining gravity and centrifugal technology. The main part is a sleeve structure, including a core tube 2 and a casing 7. The impeller 3 is installed inside the core tube 2; the inlet end of the core tube 2 is located outside the casing 7 and connected to the inlet flange 1; a support structure 14 is provided between the core tube 2 and the casing 7; the outlet of the core tube 2 The end is located inside the casing 7, and is connected with the expansion section 4, and the core pipe 2 forms an annular descending space between the part inside the casing 7 and the casing 7; the wall surface of the core pipe 2 between the impeller 3 and the expansion section 4 A hole section 5 is provided on it, and the hole section 5 is located insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com