Vibration spring-pulling mechanism

A technology of pulling springs and electric vibration, which is applied in the field of spring mattress manufacturing, can solve the problems of particularly serious impact on production, high cost of enterprise personnel, and backward working methods, so as to improve the level of production automation, reduce the intensity of work, and ensure that there is no joint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

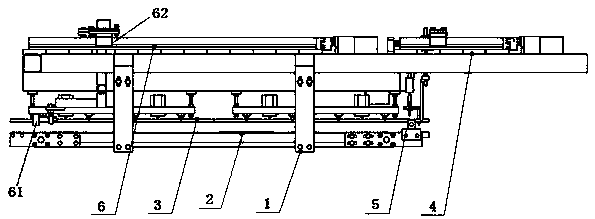

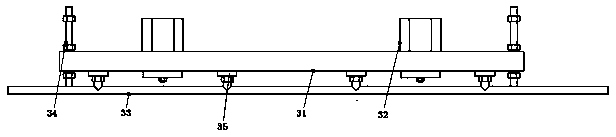

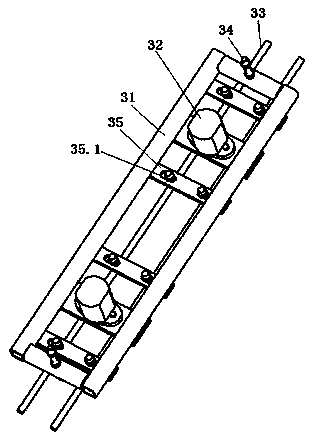

[0024] Combine below Figure 1 to Figure 6 The embodiments of the present invention will be described in detail.

[0025] The vibration dialing spring mechanism includes a horizontally arranged bracket 1, which is characterized in that the said bracket 1 is equipped with a conveyor belt 2 for conveying the spring, an electric vibration mechanism 3 for dispersing the spring, and a single spring for pulling out a single spring. The spring mechanism 4 and the circlip mechanism 5 are used to prevent a single spring from being pulled out together with adjacent springs. The springs that are tightly pushed enter from the front end of the conveyor belt 2, and the electro-vibration mechanism 2 is arranged on the top of the conveyor belt 2 to transmit to the spring. Vertical vibration, the circlip mechanism 5 is arranged above the end of the conveyor belt 2, the spring mechanism 4 is located on the rear side of the circlip mechanism 5, the circlip mechanism 5 and the spring mechanism 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com