Damping vibration attenuation frame for sling

A damping and sling technology, applied to bridge parts, bridges, buildings, etc., can solve problems such as damper fatigue damage and difficulty in suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

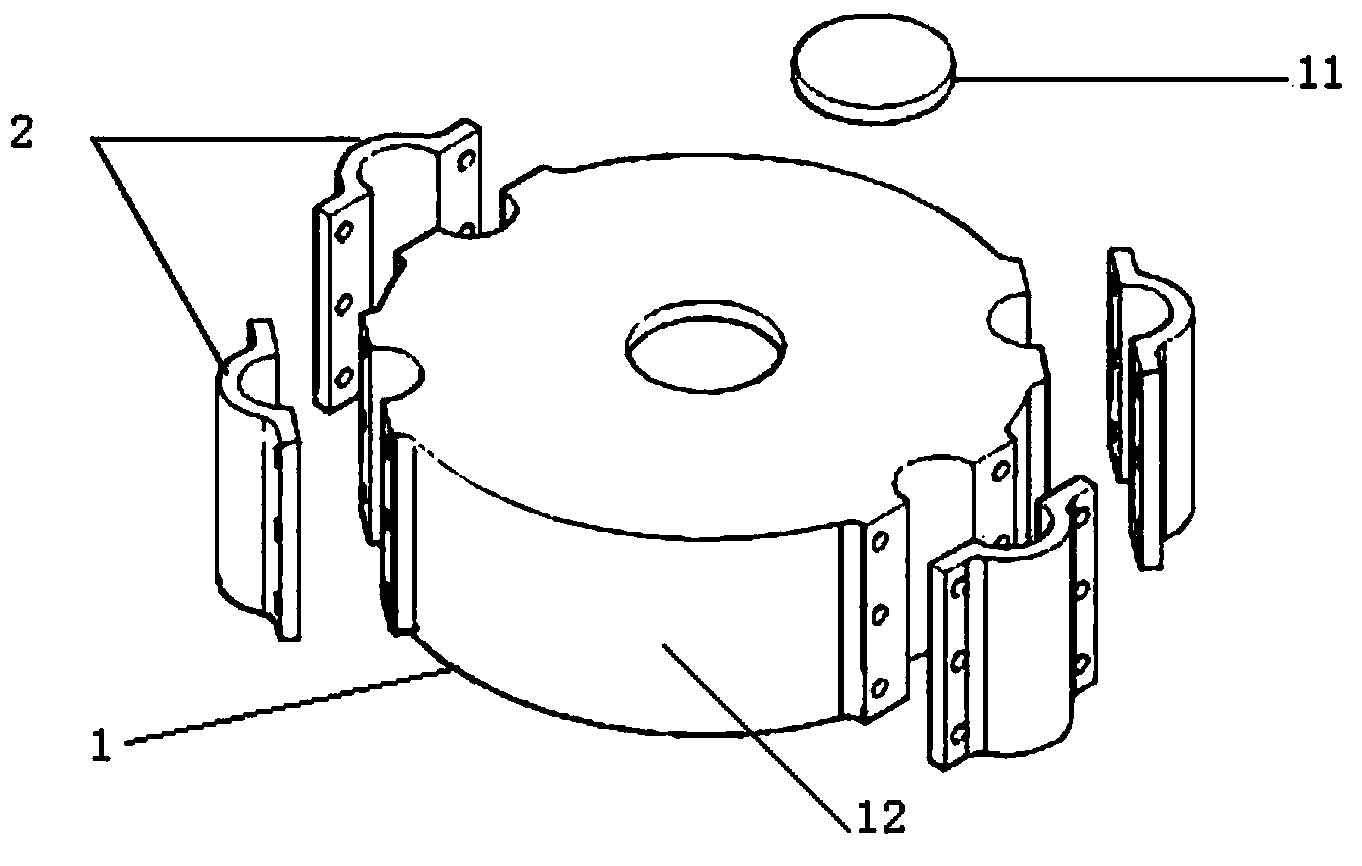

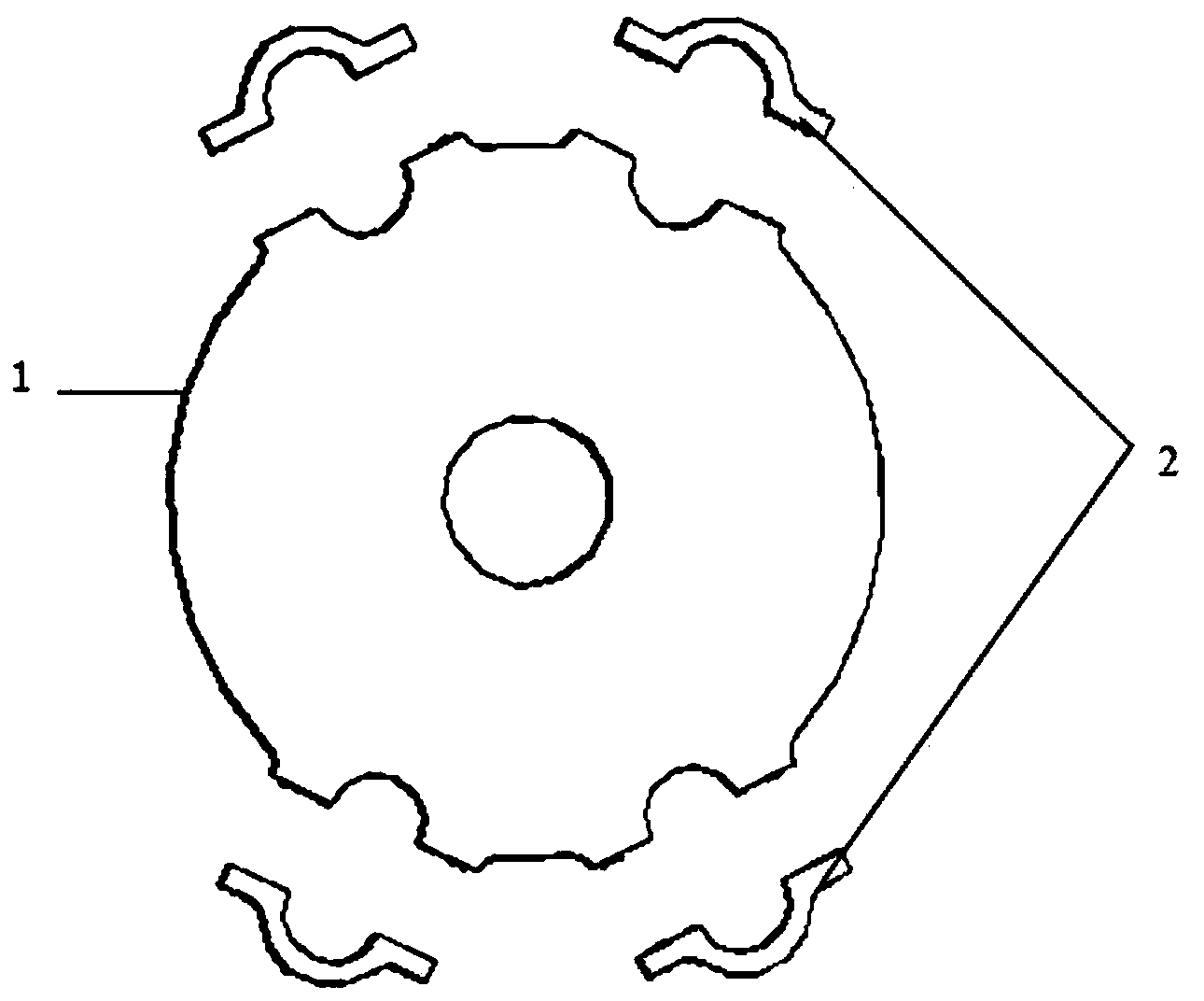

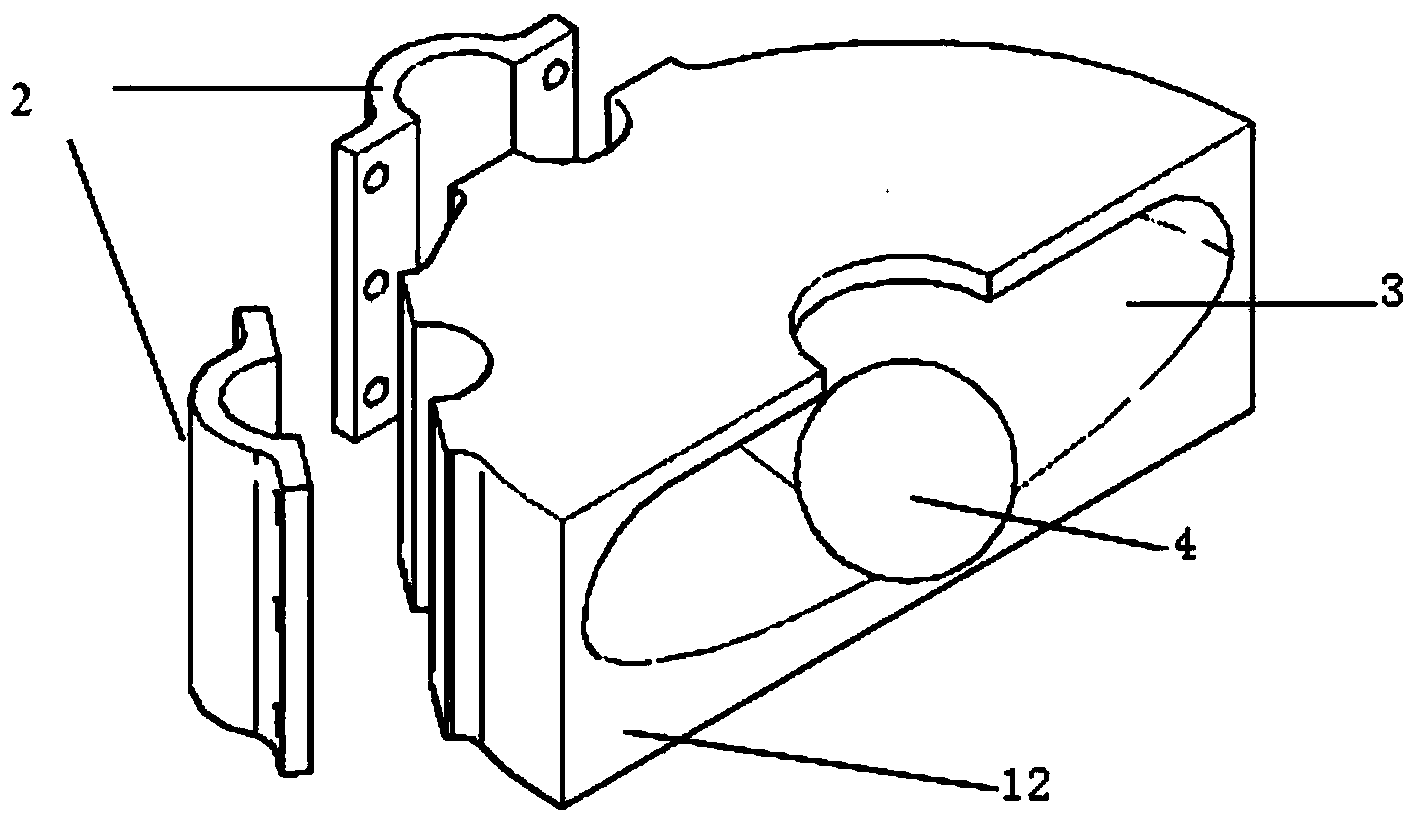

[0022] Such as Figure 1-4 As shown, a damping shock absorber for slings is used to increase the damping of suspension bridge slings, including a box-type shock absorber 1 and a cable clamp 2, the cable clamp 2 is used to connect the strands 5 of the sling, and the box The box-type vibration damping frame 1 clamps four strands 5 together with the cable clamp 2 through bolts, and the bolts used can be pre-embedded in the box-type vibration-damping frame 1, and can be attached with embedded parts for strengthening the connection. In practical applications, bolt holes can also be reserved in the box-type vibration damping frame 1, and the cable strands 5 can be clamped together with the cable clamp 2 through the bolts. The box-type vibration damping frame 1 is a box structure, and a cavity 3 is arranged inside, and an inertial mass ball 4 for vibration reduction is arranged in the cavity 3 .

[0023] Cavity 3 is filled with a viscous fluid. In this embodiment, the viscous fluid ...

Embodiment 2

[0027] The rest is the same as that of Embodiment 1, except that the viscous fluid in this embodiment is oil, and the inertial mass ball is partially submerged in the oil. The oil has a higher viscosity, and the damping effect on the inertial mass ball is more obvious. The box-type vibration damping frame is tightly connected with a cable strand, and the cable strand is installed inside the box body, and its two ends are fixed with the box body by cable clamps; the bottom surface of the cavity is a space arc surface with constant curvature, and the side The wall surface is an arc-shaped surface in space. When the box-type vibration-damping frame vibrates with the cable strands, the inertial mass ball rolls along the bottom surface and the side wall of the cavity, so that the box-type vibration-damping frame has a good vibration-damping effect.

Embodiment 3

[0029] The rest are the same as in Embodiment 1, except that the box-type vibration damping frame is tightly connected with the two strands through cable clamps, and the bottom and top surfaces of the inner cavity of the box-type vibration-damping frame are space arcs with constant curvature. When the box-type damping frame vibrates, the inertial mass ball rolls along the inner surface of the cavity when the ball of inertial mass moves inside the cavity, so that the box-type vibration-damping frame 1 has a good damping effect. vibration effect.

[0030] In the above embodiments, the viscous fluid can be any kind of fluid liquid, and can be selected according to actual needs, and there is no limitation here.

[0031] The beneficial effect of adopting the above technical scheme is: the box-type vibration damping frame is fixedly connected with one or more strands through the cable clamp, so that each strand is rigidly connected, the vibration response of each strand is reduced, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com