Pull-press self-resetting viscoelasticity energy dissipation support

An energy-dissipating support and viscoelastic technology, which is applied to building components, building types, and earthquake resistance, can solve problems such as easy loosening of bolts, asymmetrical hysteresis curves, and complex structural forms, and achieves guaranteed reset performance, symmetrical structural forms, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

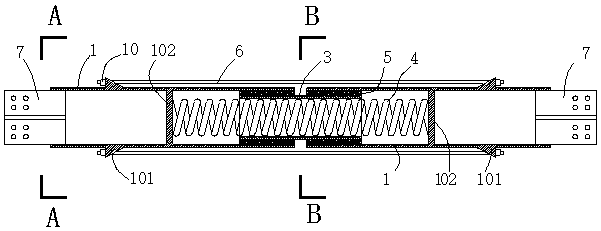

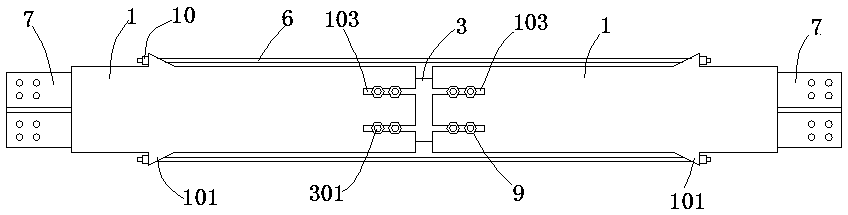

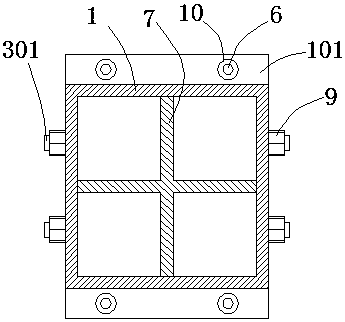

[0023] See attached Figure 1 ~ Figure 2 , the present invention is an energy-dissipating support formed by socketing an inner cylinder 3 with a spring 4 and a viscoelastic material 5 and two outer cylinders 1, the two outer cylinders 1 are provided with anchors 10, and the outer cylinder 1 is one end There is a "ten" connector 7, a sleeve with a hole 103 on both sides of the other end, and a baffle 102 inside the sleeve; the hole 103 is arranged axially, and the upper and lower parallel symmetrically arranged on the outer cylinder 1 Strip-shaped long grooves on both sides; the spring 4 is arranged in the inner cylinder 3 whose two ends are sleeved on the outer cylinder 1, and the two ends of the spring 4 resist the baffle plate 102 in the outer cylinder 1; the viscoelastic material 5 is arranged on the outer In the gap between the cylinder 1 and the inner cylinder 3; the anchor 10 is composed of a perforated triangular prism bump 101 and two high-strength bolts 6, and is symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com