Integrated tuned mass damping wall

A tuned mass damping and integrated technology, applied to building components, building structures, and earthquake resistance, can solve the problems of small vibration damping effect, large floor load, and occupying building use space, etc., to achieve stable damping energy consumption, Effect of reducing vibration response and protecting structure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

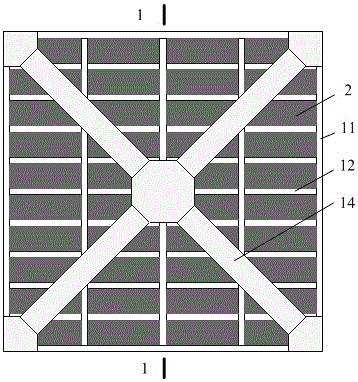

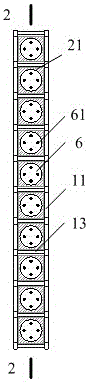

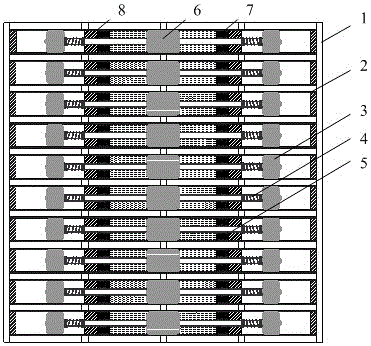

[0023] refer to Figure 1-Figure 4 As shown, the integrated tuning mass damping wall includes a bracket 1, a damping cylinder 2, an adjustment mass 3, a spring 4, a guide rod 5, a guide rod 6, a guide sleeve 7 and a connecting nut 8, and the bracket 1 is placed with Several damping cylinders 2, the damping cylinders 2 are provided with the adjustment mass 3, the spring 4, the guide rod 5, the damping mass 6, the guide sleeve 7 and the The connecting nut 8, the adjustment mass 3 and the damping mass 6 are connected to the guide rod 5, the two ends of the guide rod 5 are covered with the spring 4, and the spring 4 is in the Between the adjustment mass 3 and the connection nut 8 , the connection nut 8 is connected to the guide sleeve 7 .

[0024] Further, the damping cylinder 2 between the guide sleeves 7 is filled with viscous fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com