Hydraulic clutch brake device of punch press

A braking device and hydraulic technology, applied in the combination of coupling and brake, presses, manufacturing tools, etc., can solve the problems of difficult to ensure assembly accuracy, difficult processing, and difficult sealing, and improve the performance of the product. The effect of force relationship, reduction of processing steps, and simplification of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

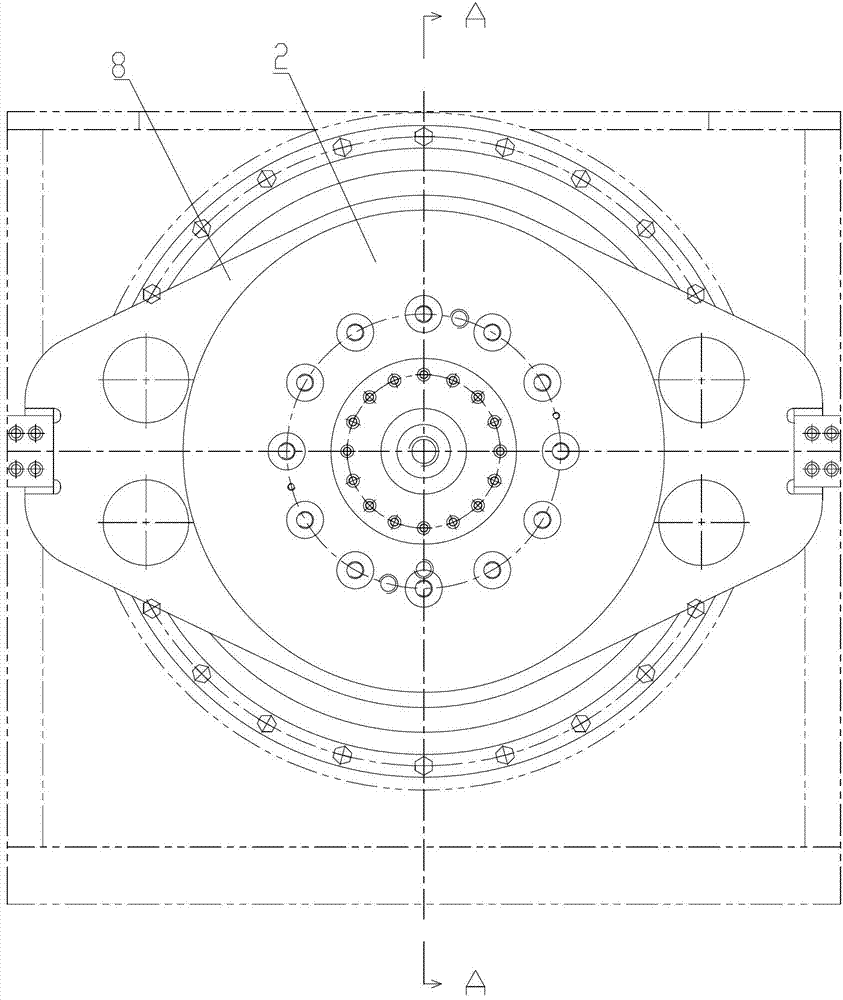

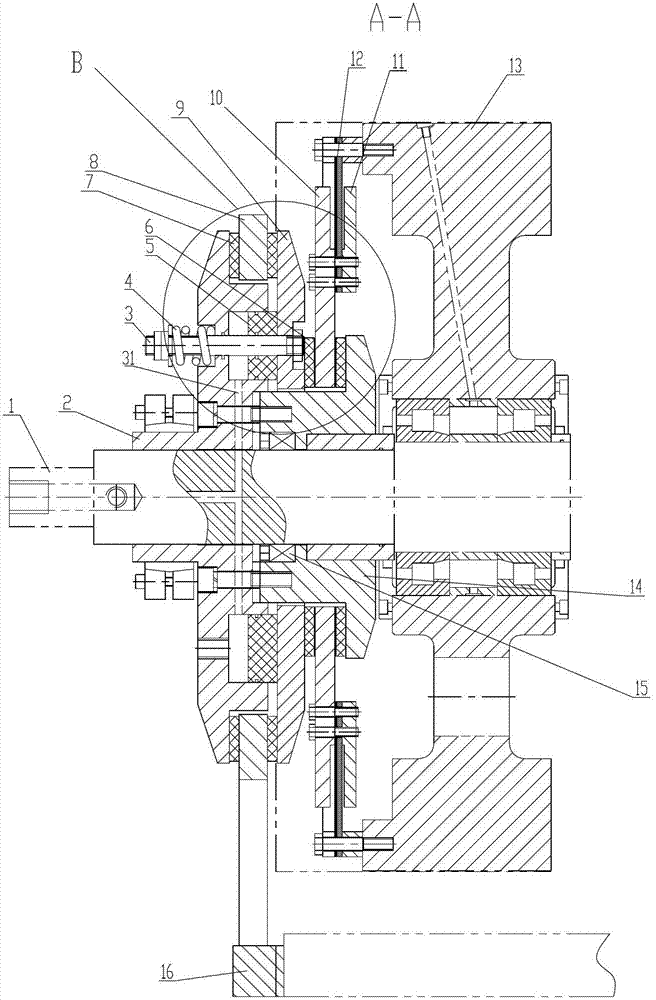

[0044] The present invention as Figure 1-18 Shown, a kind of hydraulic clutch braking device of punching machine, described punching machine comprises fuselage 16, flywheel 13, crankshaft 1 and hydraulic pressure source;

[0045] The hydraulic clutch brake device is provided between the crankshaft 1 and the flywheel 13, and the hydraulic clutch brake device includes a hydraulic cylinder 2, a working ring 9, a clutch plate 10, a spring steel plate 12 and a support sleeve 14;

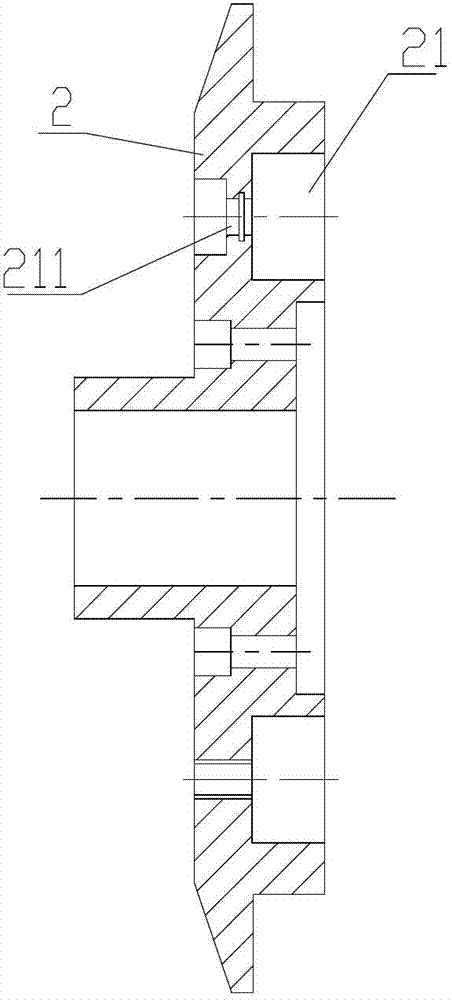

[0046] The support sleeve 14 and the hydraulic cylinder 2 are sequentially fixedly connected to the crankshaft 1, the hydraulic cylinder 2 and the support sleeve 14 are fixedly connected, and the support sleeve 14 is provided with a large step circle, and the large step The distance between the outer end surface of the circle facing the hydraulic cylinder 2 and the inner end surface of the hydraulic cylinder 2 facing the support sleeve 14 is fixed;

[0047] The working ring 9 and the clutch plate 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com