Method for monitoring vibration and strain of key parts of full-face rock tunnel boring machine

A strain monitoring, full-section technology, used in earth-moving drilling, mining equipment, tunnels, etc., to solve problems such as theoretical danger, inability to install sensors, and difficulty in TBM condition monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

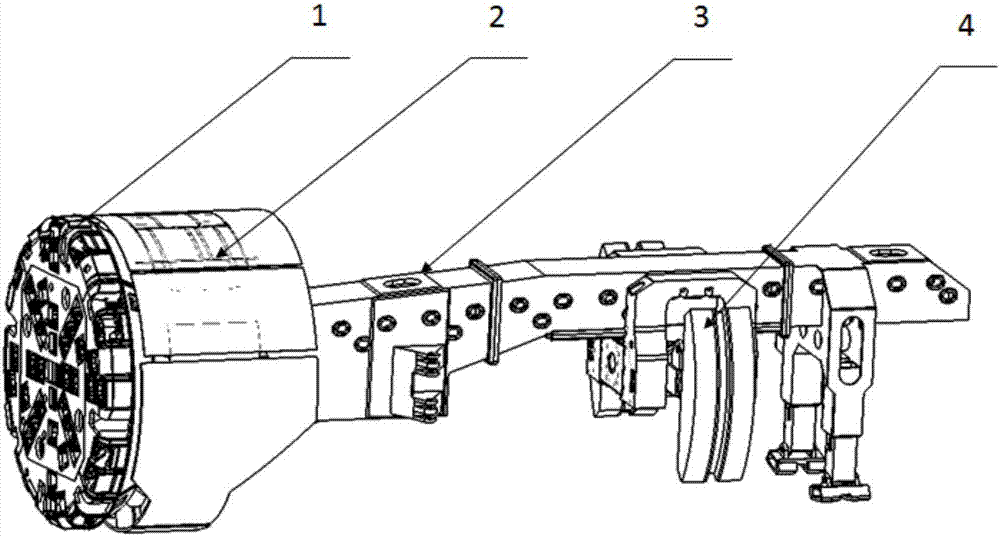

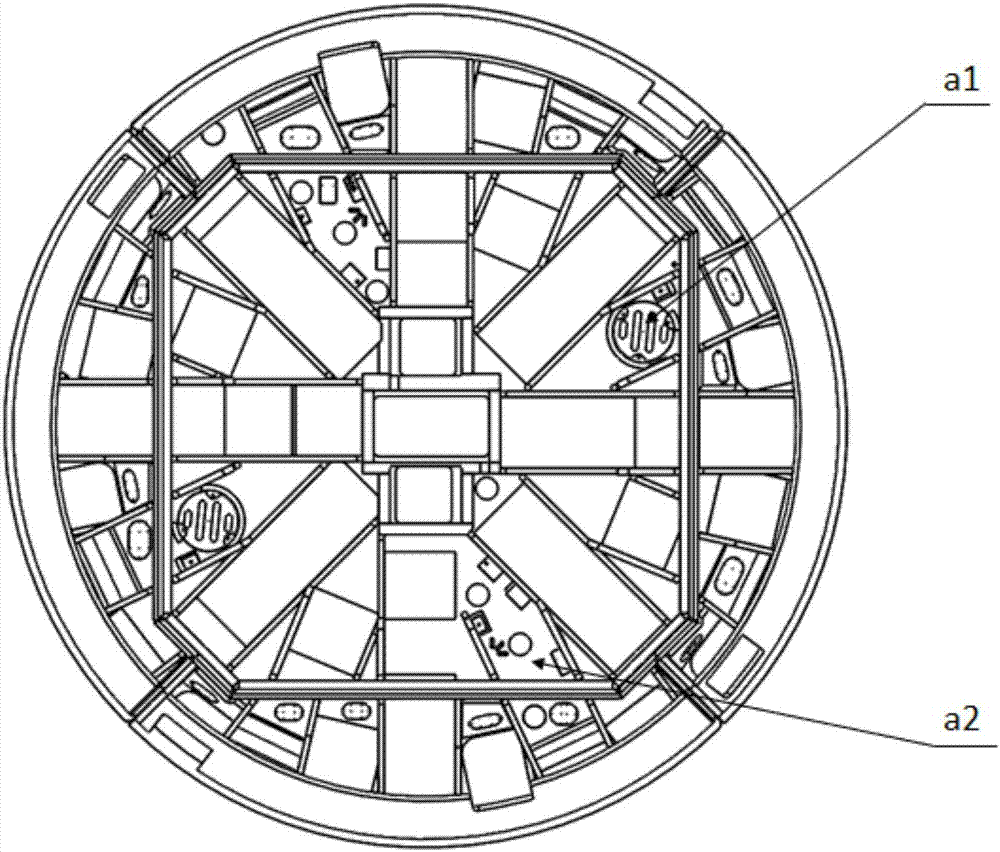

[0051] The specific embodiment of the present invention will be described in detail below in conjunction with accompanying drawings and technical solutions, figure 1 It is a schematic diagram of the TBM main engine system of a certain project, including main components such as cutter head, support shield, drive motor, main beam and support shoes. The TBM cutter head cuts rocks continuously during the working process, and the cutter head is affected by the impact of rocks. The load is relatively large and the load is transmitted to the rear parts, resulting in the vibration of the support shield, drive motor, main beam and support shoes.

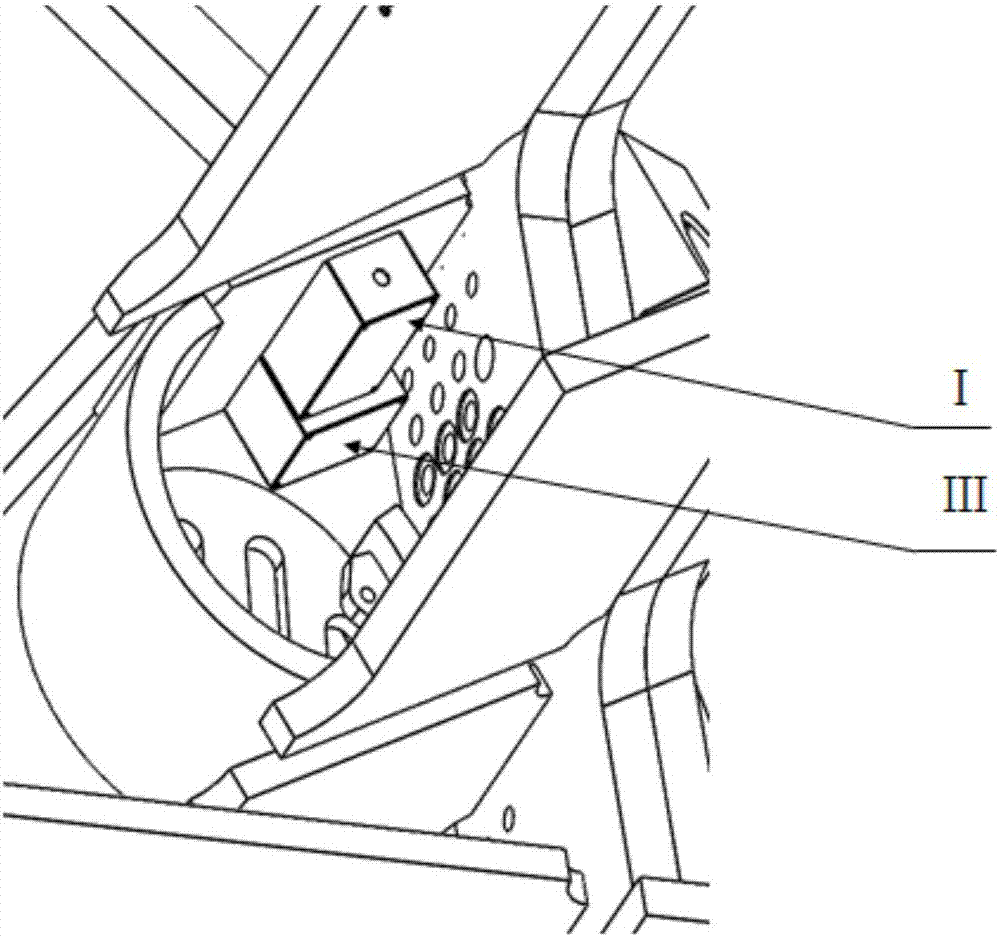

[0052] On the cutter head, the vibration sensor arranged in the water hole of the cutter head is powered by a battery. The service life of the battery is about 1 week at an appropriate sampling frequency, and the collected vibration signal passes through the antenna; it is arranged in the water hole of the cutter head The strain gauge is used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com