Inspection method for inspecting welding correctness of the device of device on circuit board in batch

A technology for inspecting circuits and inspection methods, which is applied in the direction of optical testing for flaws/defects, etc. It can solve problems such as high work intensity, missed inspections, and incompatible circuit board methods, so as to achieve high inspection efficiency, reduce labor intensity, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

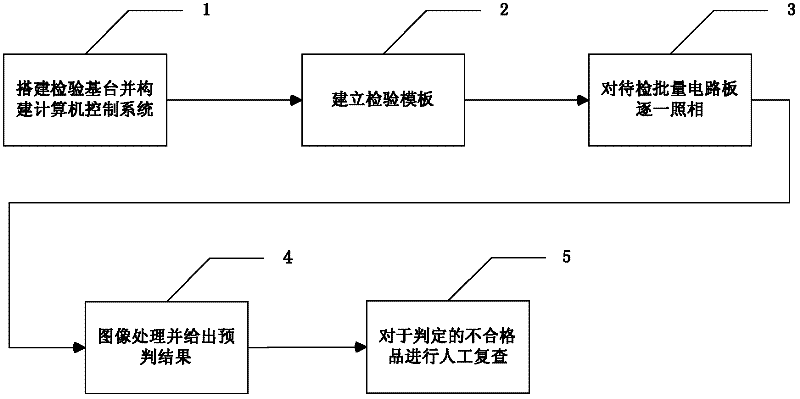

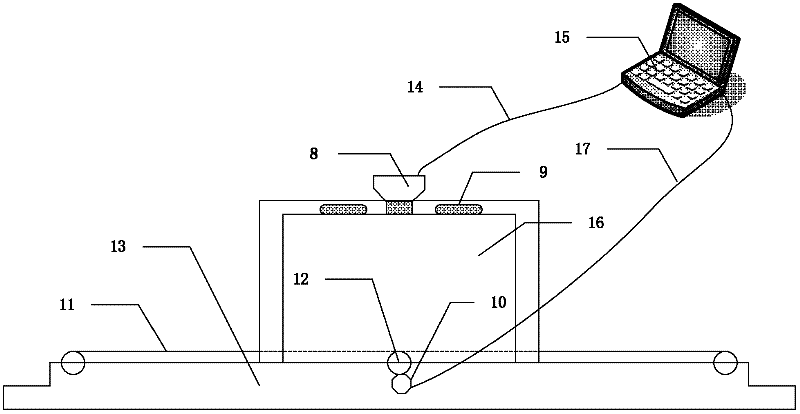

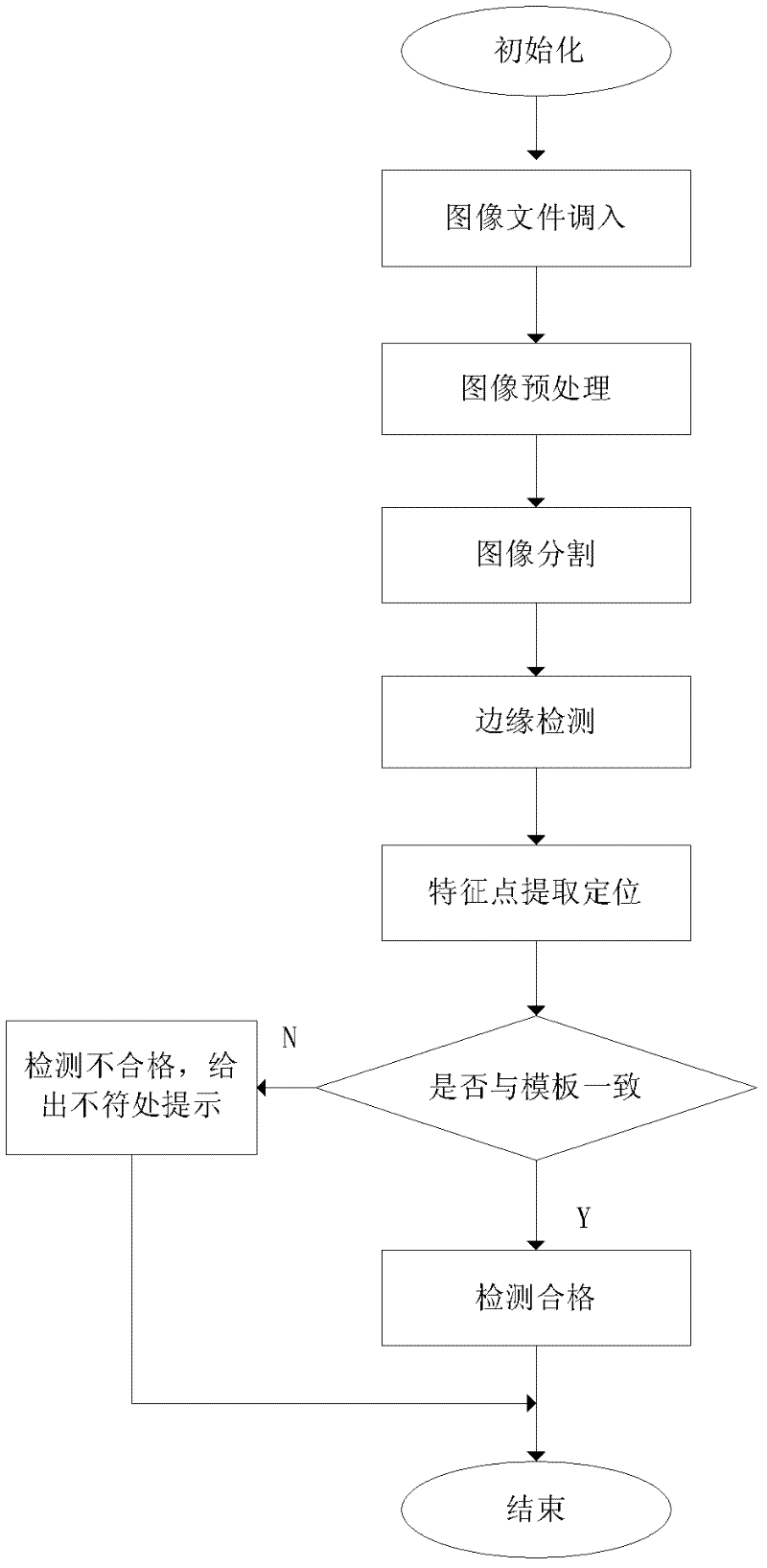

[0015] The method of the present invention presses figure 1 The flow shown is implemented, in which the inspection platform is built and the computer control system is built according to figure 2 The configuration shown is implemented.

[0016] Among them, the line-scan camera 8 adopts the Piranha 3 black-and-white line-scan camera produced by DALSA; the lighting 9 adopts the LED lighting produced by Philips; the transmission motor 10 adopts the 39BYG801 stepping motor produced by Changzhou Yameike BMW Motor Factory; Customized conveyor belt made of rubber material; transmission bearing 12 is produced by Changchun Aopu Optoelectronics Technology Co., Ltd.; base 13 is made of cast iron and manufactured by Changchun Aopu Optoelectronics Technology Co., Ltd.; computer processing equipment 15 adopts Advantech IPC-610 industrial computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com