Tool magazine and manipulator comprehensive performance detection method and platform

A technology with comprehensive performance and detection methods, applied in metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of lack of tool magazine and manipulator performance testing platform, etc., to achieve strong practicability, high precision, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Functional Overview

[0031] The purpose of the present invention is to solve the problem of lack of mature tool magazine and manipulator performance testing platform in China, and provide a tool magazine and manipulator comprehensive performance testing method and platform.

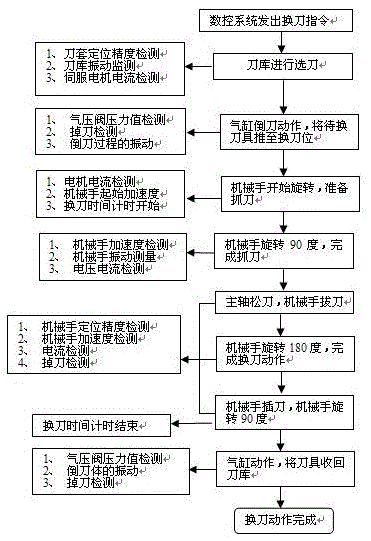

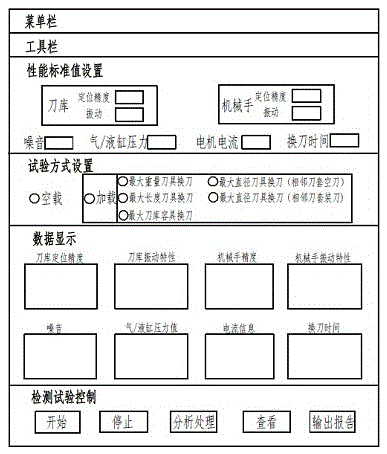

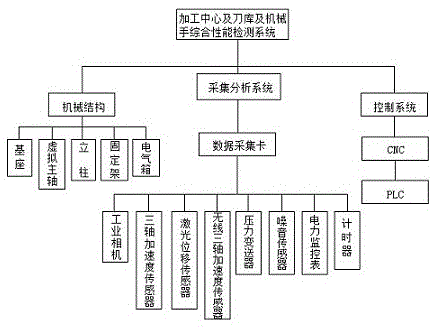

[0032] The present invention proposes a method for detecting the comprehensive performance of a tool magazine and a manipulator, such as figure 1As shown, it includes: 1) Controlling the CNC system to issue a tool change command through the man-machine interface, the tool magazine starts tool selection, and measures the vibration and noise when the tool magazine moves through the three-axis acceleration sensor and noise sensor; 2) the After the tool magazine moves in place, the industrial camera takes pictures to measure the position accuracy of the tool magazine movement; 3) The cylinder moves to complete the knife reversal, and uses the pressure transmitter to measure the pressure value of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com