Performance testing system for new energy automobile motor

A new energy vehicle and test system technology, applied in the field of new energy vehicle motor performance test system, to achieve fast replacement, avoid repeated disassembly and alignment, and improve the efficiency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings.

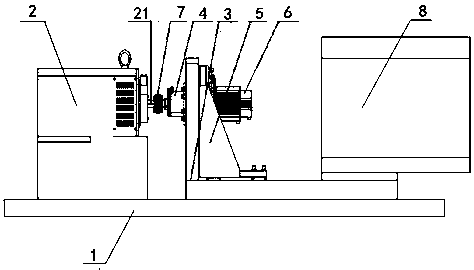

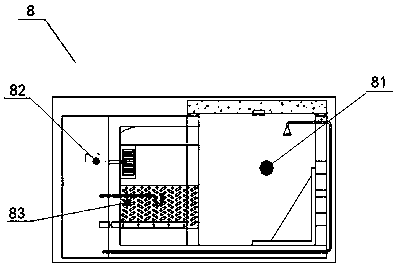

[0031] See figure 1 , figure 2 with image 3 A new energy vehicle motor performance test system shown includes a base 1 and an electric dynamometer 2 arranged on the upper left part of the base 1 and its characteristics are:

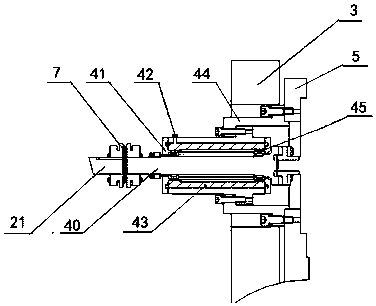

[0032] A test bench 3 is in the shape of an "L", and its straight parts are set on the middle and left parts of the base 1; the vertical part of the test bench 3 is provided with a circular hole;

[0033] A bearing cooling device 4 includes an intermediate shaft 40 arranged in the center of the bearing cooling device 4, the bearing cooling device 4 is arranged on the left side of the vertical part of the test bench 3, the bearing cooling device 4 and the test bench 3 vertical The round holes on the straight part are coaxial, and the right part of the bearing cooling device 4 is correspondingly connected with the round holes on the vertical part of the test bench 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com