Negative pressure-based device and method for manufacturing porous textures by laser sintering and quick molding

A porous structure and laser sintering technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve problems such as powder clogging, achieve fast forming speed, high precision and high forming efficiency, and guarantee the effect of porosity and pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples.

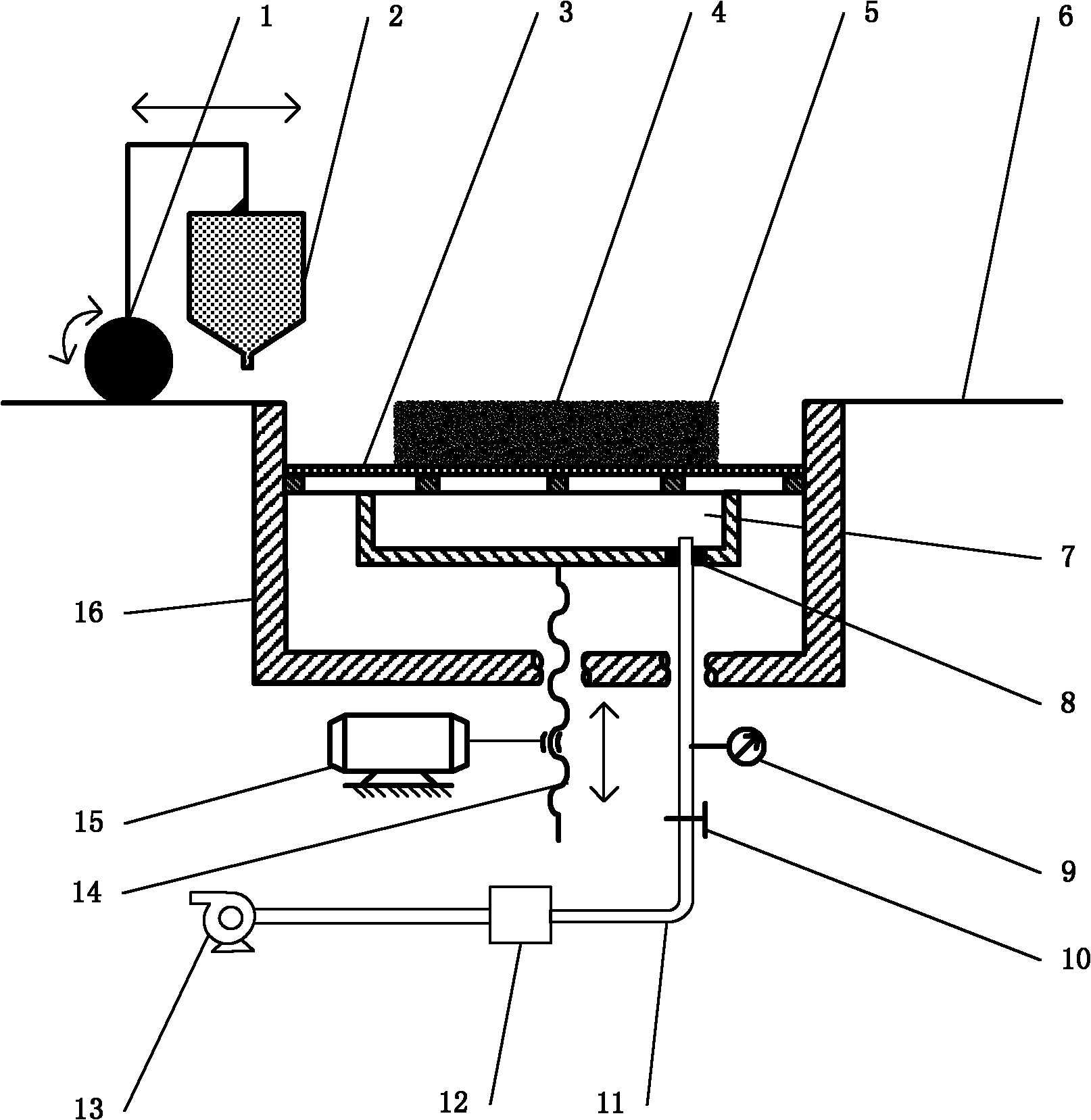

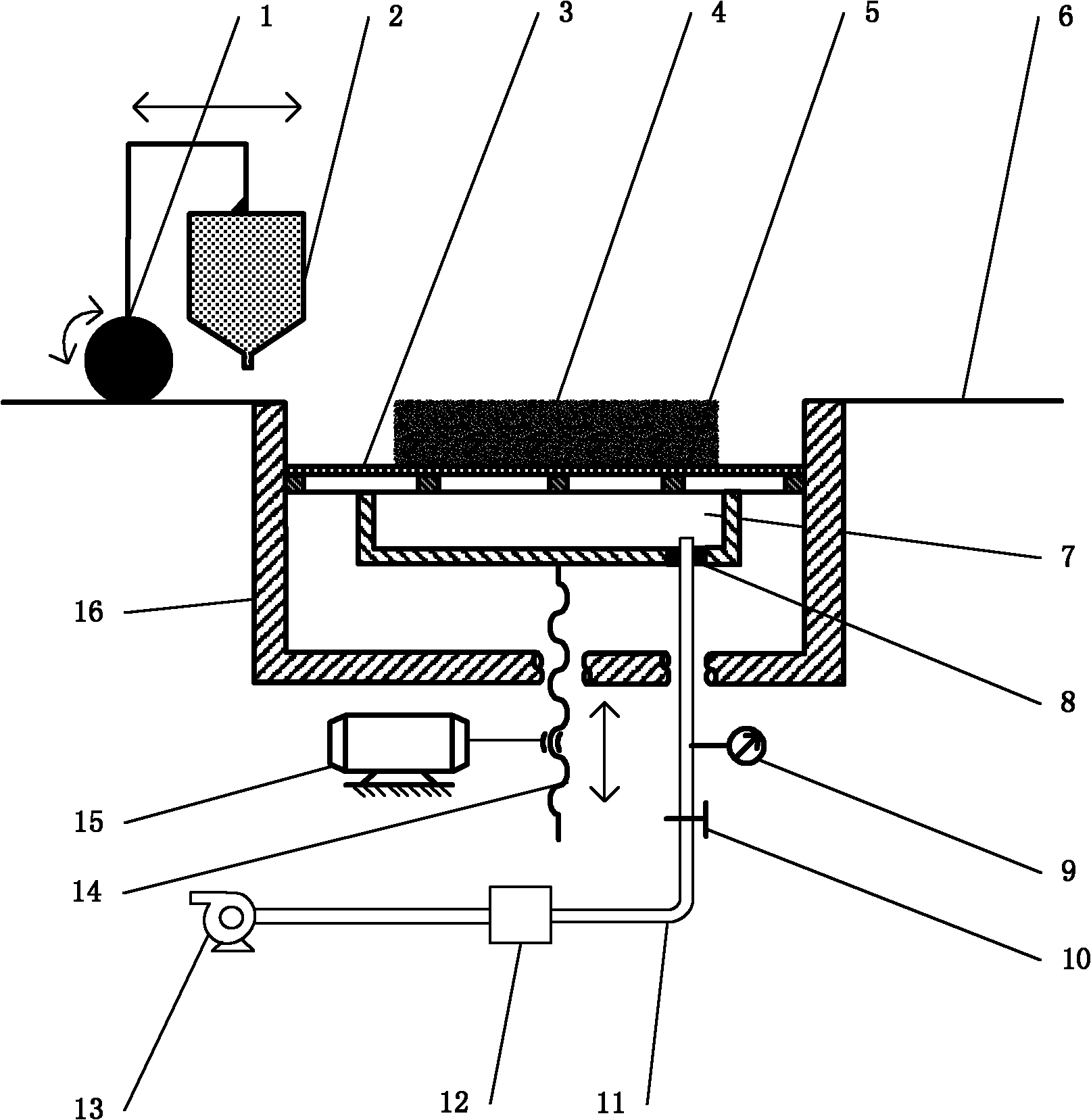

[0025] see figure 1 and figure 2 As shown, the device of the present invention includes: an X-Y working platform, on which a pair of fixed guide rails 6 are arranged in parallel, and the guide rails 6 are provided with a powder spreading roller 1 and a powder spreading groove 2 which move back and forth along the guide rails 6, and powder spreading The bottom of the tank 2 is provided with a long and narrow opening, and the opening and closing thereof is automatically controlled by an electrical device.

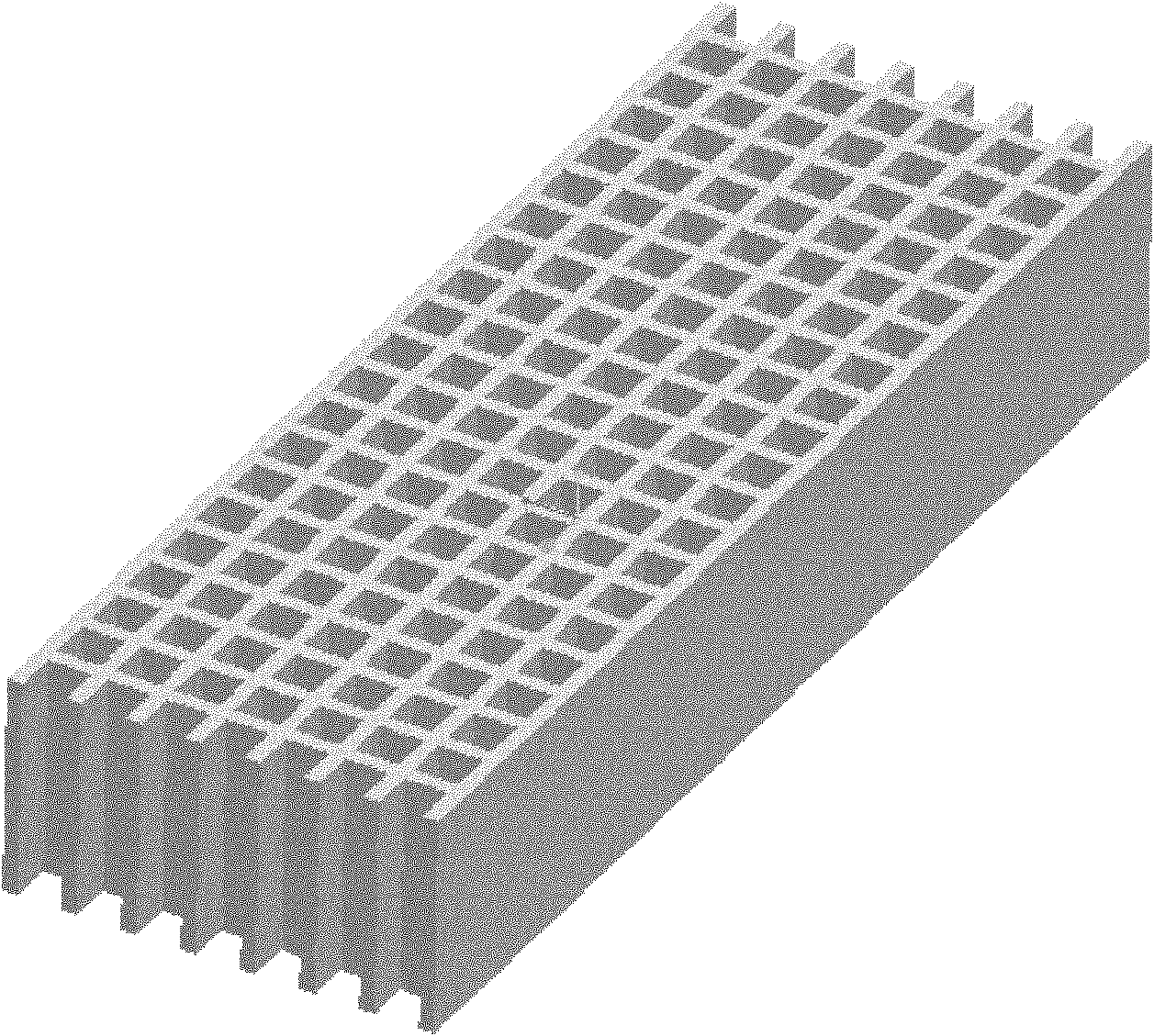

[0026] X-Y working platform is provided with forming cylinder 16, and forming cylinder 16 inside is provided with the forming workbench that can move along the vertical direction, and forming workbench is made up of mesh plate 3 and support frame 5 densely covered with small holes; Forming workbench support frame 5 The lower surface is fixed with a negative pressure chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com