Method and device for producing pressure oxygen by air separation

An air separation and pressure technology, applied in refrigeration and liquefaction, liquefaction, solidification and other directions, can solve the problems of high production cost and complex process, and achieve the effect of low equipment investment cost, improved separation capacity and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

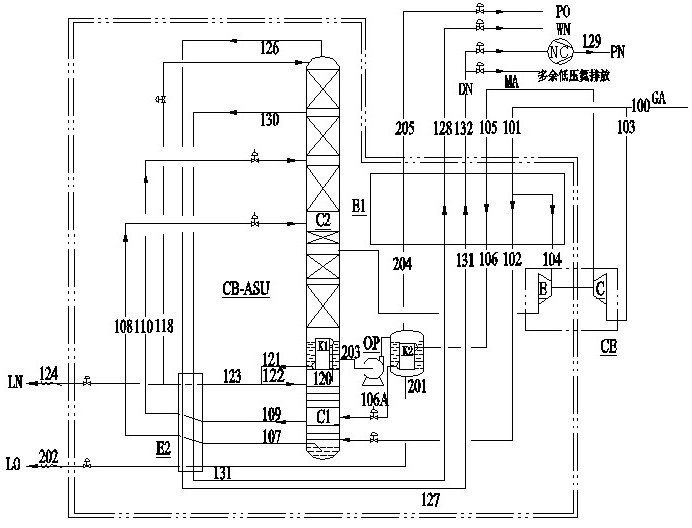

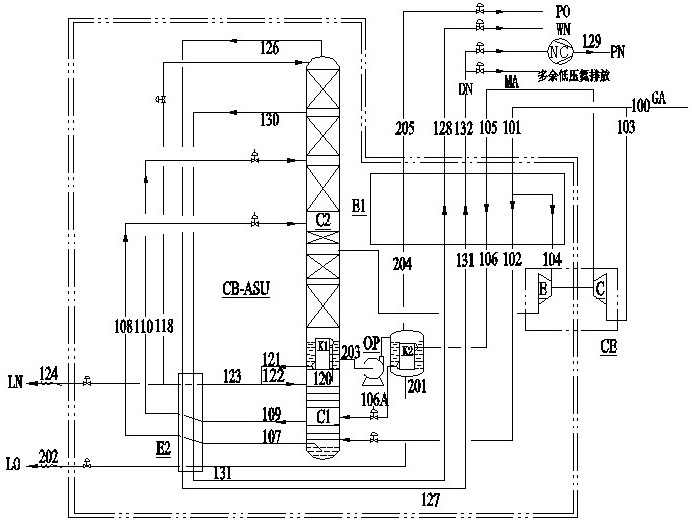

[0032] Embodiment 1: as figure 1 Shown, a kind of air separation produces the method for pressure oxygen, comprises the steps:

[0033] A. The clean compressed air 100 is divided into two paths. One path 103 is pressurized by the booster end of the expander CE and then enters the main heat exchanger E1 for cooling, and then enters the oxygen booster K2 to exchange heat with the pressure liquid oxygen to condense into a liquid state, and then Enter the rectification tower lower column C1 to participate in the rectification at a position of 3 to 7 theoretical plates from the bottom; the other path 101 enters the main heat exchanger E1 and cools down to 145K ~ 180K, and then divides into two parts, and one part 104 expands through the expansion end of the expander CE Then it is sent to the upper column C2 of the rectification tower to participate in the rectification; the other part 102 is sent to the lower tower C1 of the rectification tower, and after heat and mass transfer wit...

Embodiment 2

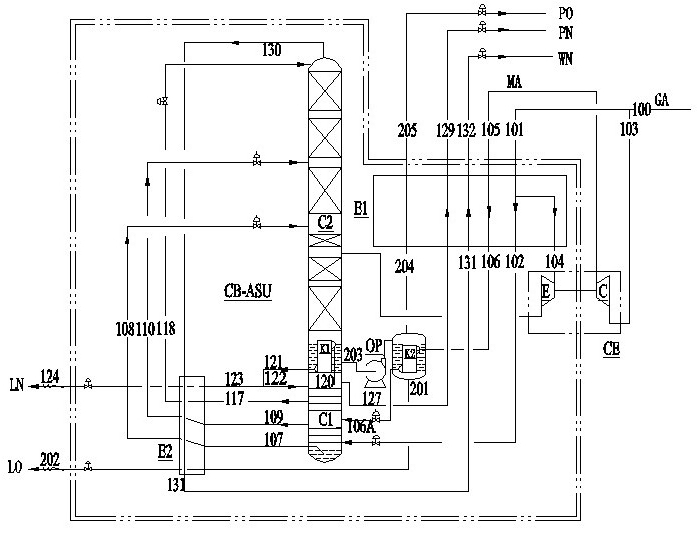

[0045] Embodiment 2: as figure 2 Shown, a kind of air separation produces the method for pressure oxygen, comprises the steps:

[0046] A. The clean compressed air 100 is divided into two paths. One path 103 is pressurized by the booster end of the expander CE and then enters the main heat exchanger E1 for cooling, and then enters the oxygen booster K2 to exchange heat with the pressure liquid oxygen to condense into a liquid state, and then Enter the rectification tower lower column C1 to participate in the rectification at a position of 3 to 7 theoretical plates from the bottom; the other path 101 enters the main heat exchanger E1 and cools down to 145K ~ 180K, and then divides into two parts, and one part 104 expands through the expansion end of the expander CE Then it is sent to the upper column C2 of the rectification tower to participate in the rectification; the other part 102 is sent to the lower tower C1 of the rectification tower, and after heat and mass transfer wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com