Method and device for rapidly reducing moisture content of sludge

A treatment method and water content technology, which is applied in the directions of dehydration/drying/thickened sludge treatment, pyrolysis treatment sludge, by-product vaporization, etc., can solve the difficulty of large-scale production, high risk of secondary pollution, and effectively kill problems such as extinction, to achieve the effects of easy large-scale treatment, making up for the long disposal cycle, and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

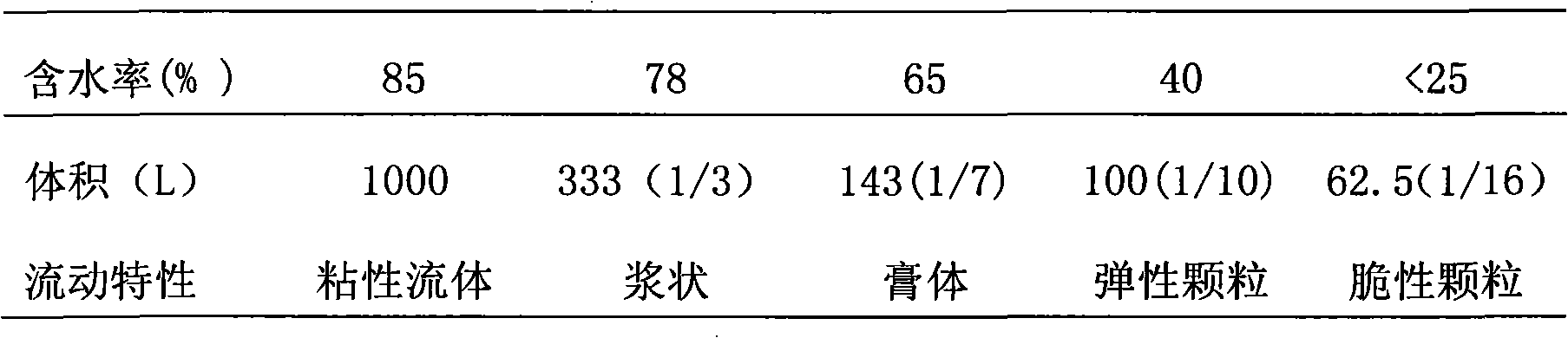

[0040] 1. First, import 2 tons of excess sludge from the sewage treatment plant into the slurry reactor for chemical catalytic hydrolysis, introduce inorganic acid sulfuric acid through the guide pipe, control the pH 5-6, control the reaction temperature (76°C-82°C), flash Steam exhausted steam back-mixing preheating pulping, steam and mechanical co-stirring, chemical catalytic hydrolysis reaction, in the pulping reactor, organic matter is hydrolyzed by atmospheric pressure steam, and a large amount of organic acids, such as oxalic acid and lignin are produced.

[0041] 2. Carry out the hydrolysis and cracking reaction of high temperature and high pressure hydrothermal dehydration, input inorganic acid catalyst (such as sulfuric acid) from the catalyst storage tank and the generated pulped sludge and organic acid into the unreacted hydrolysis tank, from the sub-cylinder to the hydrolysis reaction Steam is input into the kettle for hydrothermal dehydration. The reaction temperat...

Embodiment 2

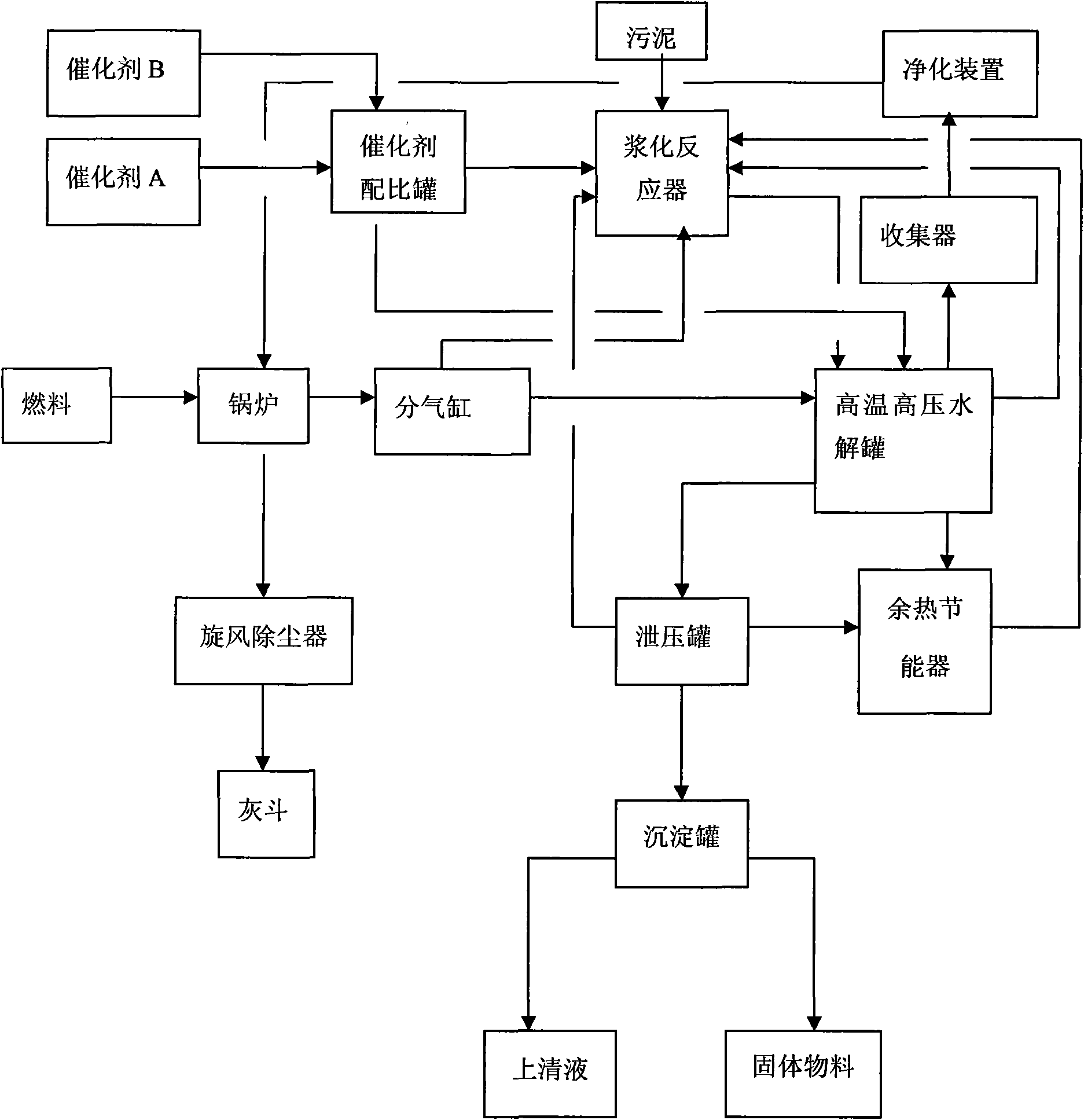

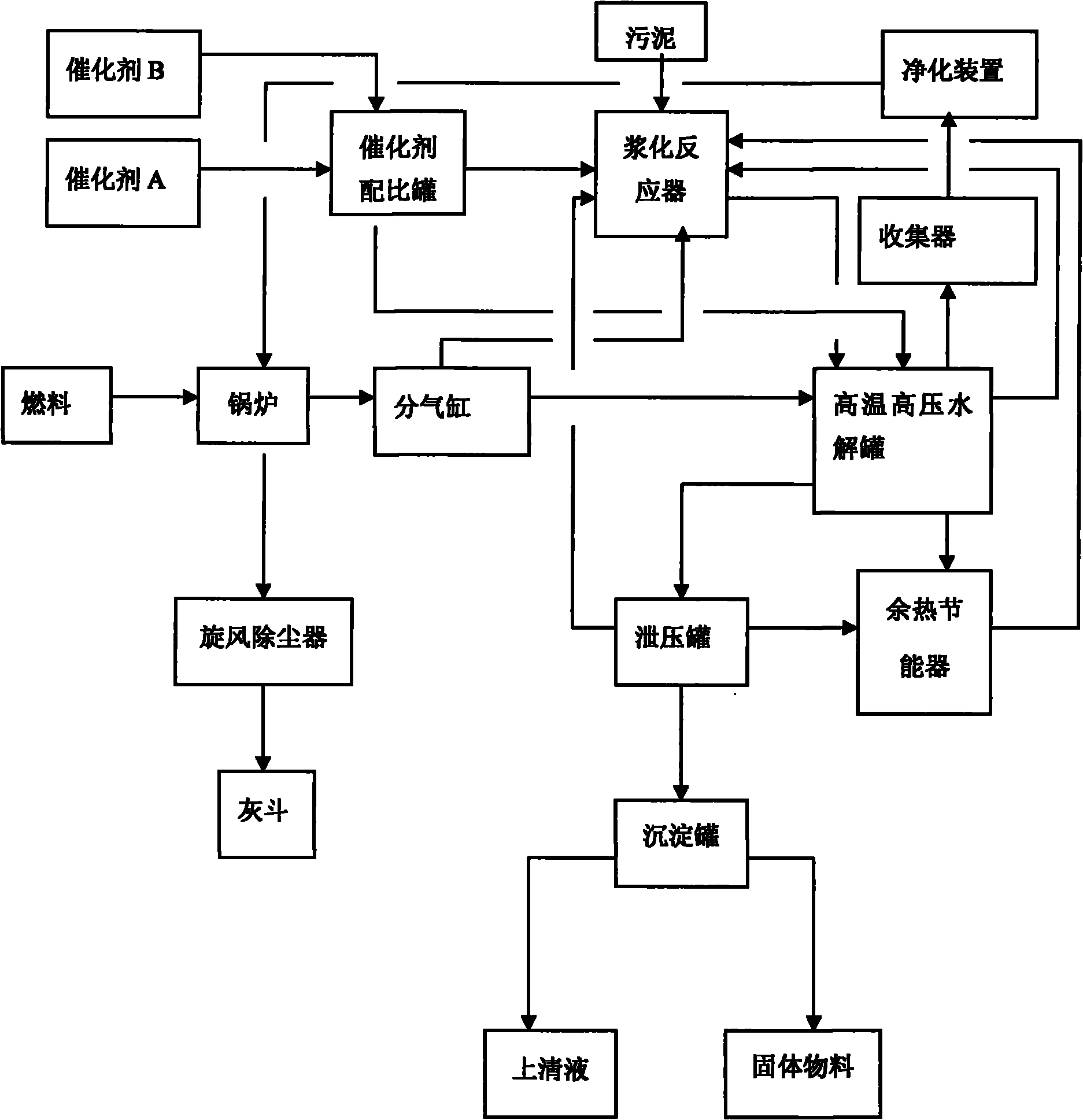

[0045] A device for rapidly reducing the moisture content of sludge, comprising: a catalyst tank for disposing catalysts, and a slurry reactor connected to the catalyst tank and reacting with imported sludge;

[0046] A high-temperature and high-pressure hydrolysis tank that is connected to the slurry reactor, the catalyst tank and the sub-cylinder respectively to allow the sludge organic matter to undergo a chemical catalytic cracking reaction to generate small molecular carbides and nitrides;

[0047] The high-temperature and high-pressure hydrolysis tank is connected to a pressure relief tank for pressure relief and exhaust; the pressure relief tank is connected to a pair of sedimentation tanks for hydrolyzed sludge for sedimentation and separation to generate solid materials and supernatant.

[0048] The pressure relief tank is also connected to a pulping reactor through a waste heat economizer connected in the middle. In the pulping reactor, organic matter is hydrolyzed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com